click image to enlarge

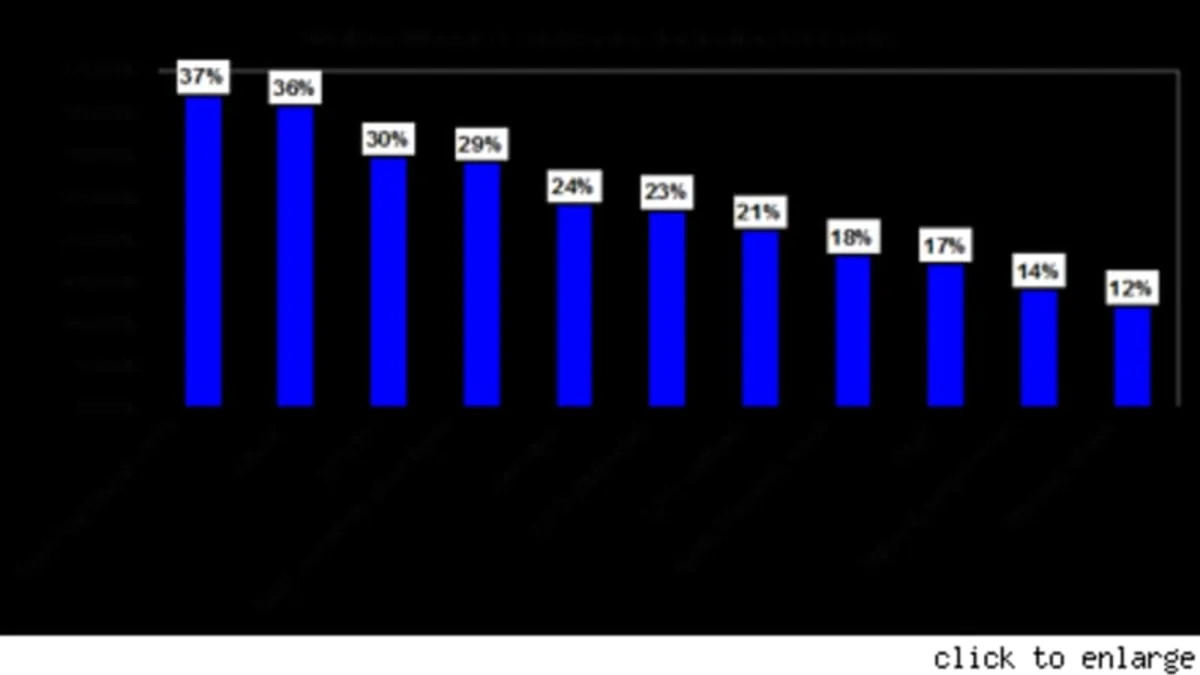

It's no surprise that advocacy groups release statistics that promote the group's mission. The latest greener driving groups to do so is Clean Air Power (CAP) with the chart above (you can see a more readable version by clicking on the image). CAP is releasing the data as part of an effort to encourage the UK government to use a standard Wells to Wheels (WTW) method of figuring energy efficiency for vehicles. Notably missing in CAP's chart: electric vehicles.

Aside from this omission, CAP's Dual-Fuel system is "proven to be the most carbon-efficient fuel option." You can read CAP's reasoning after the jump. I'll just agree that taking fuel production into account is the responsible thing to do when discussing energy, leaving EVs off the chart is not.

Related:

PRESS STATEMENT

For immediate release

31.7.07

CLEAN AIR POWER CALLS FOR 'WELL TO WHEELS' EMISSIONS ANALYSIS MODEL TO BE ADOPTED AS STANDARD IN THE HEAVY GOODS TRANSPORT INDUSTRY

Dual-Fuel™ proven to be the most carbon-efficient fuel option

Steve Whelan, Technology Director, Clean Air Power urges the transport industry to standardise measurement of emissions by using the 'Well To Wheels' (WTW) evaluation formula. This gives a true and realistic figure for all fuels from source to powering the engine, rather than simply taking the emission reading from the exhaust. It covers all stages of the fuel cycle, from energy and feedstock recovery in the case of biofuels, to energy delivered to the vehicle's wheels.

As early as 1995, with funding from the US Department Of Energy's (DOE) Office of Transportation Technologies, the GREET model was developed by the Argonne National Laboratory, one of the US DOE's largest research centres, as an analytical tool to estimate WTW energy use and emissions associated with transportation fuels and advanced vehicle technologies. This model separately calculated:

* Fuel-cycle energy consumption for total energy (all energy sources), fossil fuels (petroleum, Natural Gas and coal), and petroleum

* Fuel-cycle emissions of GHGs – CO2, Methane and N2O

* Fuel-cycle emissions of five criteria pollutants, separated into urban and total emissions – Volatile Organic Compounds, CO, NOx, particulate matter and SOx

Since then, WTW has formed the basis of numerous high level studies into viable alternative fuel around the world. This includes the study of WTW Energy Use commissioned by the US DOE, and the more recent evaluation of bio-methane in the research paper 'Fuelling the Future', produced by Biogas West and Business Region Göteborg, Sweden.

Steve says: "We believe that WTW gives the true reading of emissions from source to powering the vehicle and should be adopted by the heavy goods transport industry in the UK, and in fact globally. Our technical team has used the WTW formula to calculate the efficiency of Dual-Fuel™, using Natural Gas substitution of diesel. The results are extremely positive, and provide further evidence that our technology delivers an immediate solution to substantially reduce CO2 emissions and generate cost savings."

As shown in the table above, using the WTW emissions model, fuelling a standard diesel engine with Natural Gas (NG), facilitated by Dual-Fuel™ technology equals the best current WTW-efficient fuel. As NG contains less carbon and more energy than diesel, the Dual-Fuel™ WTW efficiency translates into a c.20% reduction in WTW carbon footprint over diesel.

In the drive to cut pollutant – air quality related – exhaust emissions, especially particulates (soot), NG is a clear winner. Whether delivered in compressed (CNG) or liquefied (LNG) form, it scores highly in any WTW evaluation. NG drawn from the earth's plentiful underground reserves has high methane and energy content and requires minimal energy-intensive processing, other than compression or liquefaction and transportation.

When engines are fuelled with NG in the form of renewable bio-methane, the WTW balance is even more favourable, the gas being produced typically close to the point of use, minimising tanker or pipeline costs. Furthermore, the fuel is wholly renewable. When Bio-methane is considered, the WTW carbon footprint can approach zero as Bio-methane production gives the best energy yield per hectare of any bio-fuel. Dual-Fuel™ operates with bio-diesel and bio-methane. As Dual-Fuel™ uses the liquid fuel as an ignition source only; it requires only a fraction of the liquid fuel of a conventional diesel engine. Therefore, it makes best use of the scarce bio-diesel resources and the plentiful bio-methane sources. With the shortage of available land for low-yield bio-diesel production, Dual-Fuel™ has the potential to optimise the use of bio-fuels; taking what is available and using it efficiently.

A Dual-Fuel™ engine running on bio-methane with bio-diesel in its 'pilot' fuel tank – brings together the fuel's WTW attributes and the universally acknowledged fuel efficiency of the Diesel combustion cycle. As a fuel-engine combination it offers the highest possible WTW energy efficiency, which translates also into low greenhouse gas (CO2) and air-quality emissions. When whole-life costings for the truck or bus operator are also taken into account, Dual-Fuel™ technology based on bio-fuel usage offers a unique blend of environment-friendliness and attractive economics.

It's no surprise that advocacy groups release statistics that promote the group's mission. The latest greener driving groups to do so is Clean Air Power (CAP) with the chart above (you can see a more readable version by clicking on the image). CAP is releasing the data as part of an effort to encourage the UK government to use a standard Wells to Wheels (WTW) method of figuring energy efficiency for vehicles. Notably missing in CAP's chart: electric vehicles.

Aside from this omission, CAP's Dual-Fuel system is "proven to be the most carbon-efficient fuel option." You can read CAP's reasoning after the jump. I'll just agree that taking fuel production into account is the responsible thing to do when discussing energy, leaving EVs off the chart is not.

Related:

- Biomethane mixed with natural gas or diesel to make heavy vehicles greener

- Clean Air Power coming to Mitchell Corp. freight trucks in Australia

- Diesel-natural gas dual-fuel retro-fit systems from Clean Air Power coming out clean

- Clean Air Power's diesel-natural gas conversion system could help Britain reach Kyoto targets

PRESS STATEMENT

For immediate release

31.7.07

CLEAN AIR POWER CALLS FOR 'WELL TO WHEELS' EMISSIONS ANALYSIS MODEL TO BE ADOPTED AS STANDARD IN THE HEAVY GOODS TRANSPORT INDUSTRY

Dual-Fuel™ proven to be the most carbon-efficient fuel option

Steve Whelan, Technology Director, Clean Air Power urges the transport industry to standardise measurement of emissions by using the 'Well To Wheels' (WTW) evaluation formula. This gives a true and realistic figure for all fuels from source to powering the engine, rather than simply taking the emission reading from the exhaust. It covers all stages of the fuel cycle, from energy and feedstock recovery in the case of biofuels, to energy delivered to the vehicle's wheels.

As early as 1995, with funding from the US Department Of Energy's (DOE) Office of Transportation Technologies, the GREET model was developed by the Argonne National Laboratory, one of the US DOE's largest research centres, as an analytical tool to estimate WTW energy use and emissions associated with transportation fuels and advanced vehicle technologies. This model separately calculated:

* Fuel-cycle energy consumption for total energy (all energy sources), fossil fuels (petroleum, Natural Gas and coal), and petroleum

* Fuel-cycle emissions of GHGs – CO2, Methane and N2O

* Fuel-cycle emissions of five criteria pollutants, separated into urban and total emissions – Volatile Organic Compounds, CO, NOx, particulate matter and SOx

Since then, WTW has formed the basis of numerous high level studies into viable alternative fuel around the world. This includes the study of WTW Energy Use commissioned by the US DOE, and the more recent evaluation of bio-methane in the research paper 'Fuelling the Future', produced by Biogas West and Business Region Göteborg, Sweden.

Steve says: "We believe that WTW gives the true reading of emissions from source to powering the vehicle and should be adopted by the heavy goods transport industry in the UK, and in fact globally. Our technical team has used the WTW formula to calculate the efficiency of Dual-Fuel™, using Natural Gas substitution of diesel. The results are extremely positive, and provide further evidence that our technology delivers an immediate solution to substantially reduce CO2 emissions and generate cost savings."

As shown in the table above, using the WTW emissions model, fuelling a standard diesel engine with Natural Gas (NG), facilitated by Dual-Fuel™ technology equals the best current WTW-efficient fuel. As NG contains less carbon and more energy than diesel, the Dual-Fuel™ WTW efficiency translates into a c.20% reduction in WTW carbon footprint over diesel.

In the drive to cut pollutant – air quality related – exhaust emissions, especially particulates (soot), NG is a clear winner. Whether delivered in compressed (CNG) or liquefied (LNG) form, it scores highly in any WTW evaluation. NG drawn from the earth's plentiful underground reserves has high methane and energy content and requires minimal energy-intensive processing, other than compression or liquefaction and transportation.

When engines are fuelled with NG in the form of renewable bio-methane, the WTW balance is even more favourable, the gas being produced typically close to the point of use, minimising tanker or pipeline costs. Furthermore, the fuel is wholly renewable. When Bio-methane is considered, the WTW carbon footprint can approach zero as Bio-methane production gives the best energy yield per hectare of any bio-fuel. Dual-Fuel™ operates with bio-diesel and bio-methane. As Dual-Fuel™ uses the liquid fuel as an ignition source only; it requires only a fraction of the liquid fuel of a conventional diesel engine. Therefore, it makes best use of the scarce bio-diesel resources and the plentiful bio-methane sources. With the shortage of available land for low-yield bio-diesel production, Dual-Fuel™ has the potential to optimise the use of bio-fuels; taking what is available and using it efficiently.

A Dual-Fuel™ engine running on bio-methane with bio-diesel in its 'pilot' fuel tank – brings together the fuel's WTW attributes and the universally acknowledged fuel efficiency of the Diesel combustion cycle. As a fuel-engine combination it offers the highest possible WTW energy efficiency, which translates also into low greenhouse gas (CO2) and air-quality emissions. When whole-life costings for the truck or bus operator are also taken into account, Dual-Fuel™ technology based on bio-fuel usage offers a unique blend of environment-friendliness and attractive economics.

Sign in to post

Please sign in to leave a comment.

Continue