Recently, we ran an article: LeefH2 wants to clean up pretty much every diesel engine and it mentioned the way HNO Green Fuels, the maker of the LeefH2, wants to create oxygen from a diesel engine while also reducing particulate matter. I had some concerns with that.

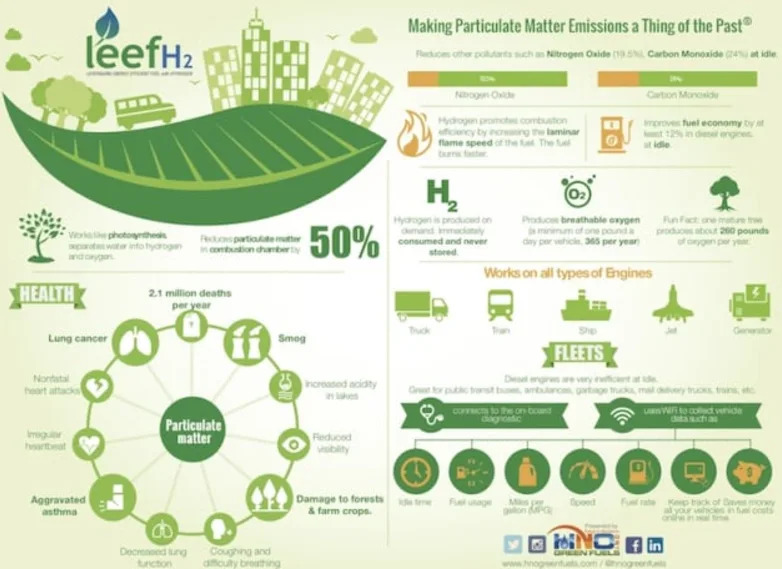

Turn your diesel engine into an oxygen farm? Really? LeefH2 supposedly works by breaking the water molecule up into hydrogen and oxygen, releasing oxygen into the atmosphere and then burning hydrogen in the fuel mixture. Except that when hydrogen is burned it bonds again with oxygen from the atmosphere, so the net oxygen produced by this scheme? Zero!

HNO harps on a strange claim in their promotional video:

The problem with the "scheme" is Newton's Third Law of Motion: For every action there is an equal but opposite reaction. Non-engineers sometime think electricity in a car is free, but producing electricity in a car increases the load on the engine, reduces fuel efficiency and actually costs about $0.50 per kWhr in a car: more than 4 times what electricity costs at home. Similar things have been tried by many, including a product announcement by the beloved Malcolm Bricklin which never came to market.

Automobiles are designed to produce enough electricity to run all the systems in the car simultaneously. When you add extra loads like an "electrolyzer," the alternator will burn out. So for this scheme to work the current must be kept very low. Except that hydrogen produced through electrolysis at 12V at a low current will have a very low efficiency: probably much less than 50 percent. This means it takes twice as much energy to produce the hydrogen than is produced when the hydrogen is burned, which wastes energy.

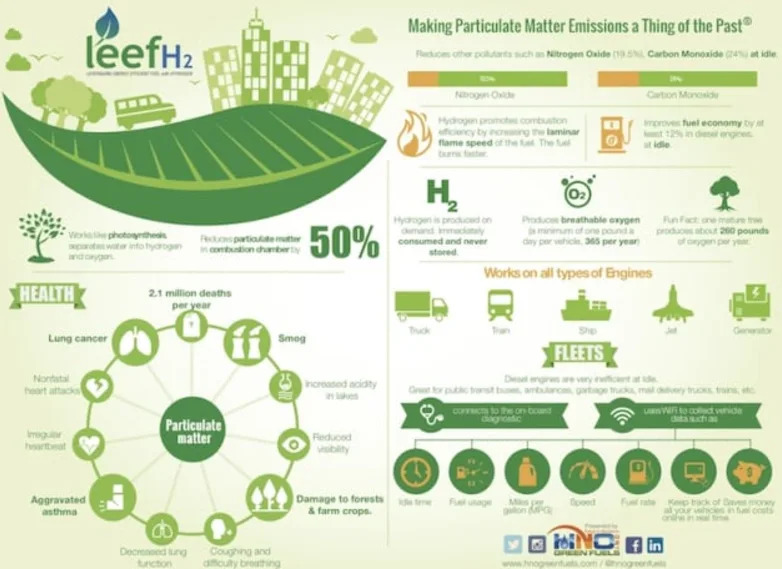

LeefH2 says that the efficiency of the diesel burn is so dramatically improved that it makes up for this loss in efficiency caused by producing the hydrogen. The idea is that hydrogen burns so quickly that it will make the diesel burn more thoroughly. Except that nobody can ever demonstrate that the improved diesel burn makes up for the loss in efficiency.

HNO's slick promotional video to get you to part with your money is also flat out wrong about clean diesel: advanced new technologies such as electronic controls, common rail fuel injection, variable injection timing, improved combustion chamber configuration and turbocharging definitely improve diesel combustion.

All internal combustion automobile engines (diesel and gasoline alike) today use electronic fuel injection controlled by a computer located somewhere in your car. Computer software controls how much fuel and air are combined based on a slew of variables to produce the most efficient burn possible. When hydrogen (which in this case is a fuel), normally not present in the air we breathe, is added to the engine air intake, the entire software to optimize the engine and reduce pollution is compromised. And unlike diesel or gasoline fuel which are precisely controlled by fuel injectors, the LeefH2 just allows hydrogen fuel to be added to the air intake without any regulation.

A group called Performance, Innovation, Transport investigated hydrogen injection claims (but not LeefH2 specifically, as far as we know), and writes in Hydrogen Injection: Myths and Facts that, "Contrary to manufacturer claims, none of these technologies has shown any ability to reduce vehicle fuel consumption."

Just like other contraptions which are supposed to reduce fuel consumption, if there was really something to the LeefH2 major automobile manufacturers would have implemented it a long time ago. If you want to lower fuel consumption and reduce emissions (and keep your money in your pocket) the US Department of Energy has some excellent suggestions you can follow which really do work.

So, those are my concerns with the LeefH2 technology. In the spirit of fairness, I asked a number of questions to HNO Fuels' Donald Owens. Owens has a mechanical-electrical engineering degree from Kettering University (formerly General Motors Institute) and a law degree from the Georgetown University Law Center.

===

ABG: What voltage does the HNO Electrolyzer use to perform electrolysis?

Owens: We have two different electrolyzer products. One is the LVU (Low volume unit) and the other is an HVU (High volume unit)

The LVU needs between 10.5 and 14 volts to operate. We are using PEM (Polymer Electrolyte Membrane) to accomplish the electrolysis of water. This particular cell/stack design uses two volts per cell and we are currently using a seven-cell stack in our LVU although we can add cells for application that may require a little more hydrogen than the current LVU produces, but not as much as what the HVU provides.

The HVU is a different cell/stack configuration and also requires 2 volts per cell, but the surface area of the cells are much larger and draws more current. Depending upon the configuration of the HVU (and hence the application), the voltage can be as low as eight to as high 30 for the applications we currently have in mind right now. However, the one we are testing has six cells and can operate on nine-to-12 volts.

ABG: How much current does the HNO Electrolyzer use?

Owens: The LVU uses from 3.5 to 5 amps. The HVU, as high as 40 - 50 amps.

ABG: Can the Electrolyzer be mounted on its side, or does it need to be facing upright to function?

Owens: The electrolyzer itself can be mounted on "its side" and still function, but in our application the water is "gravity fed" to our electrolyzers, hence the device itself (HVU or LVU) needs to be upright, if for no other reason for gravity to feed the electrolyzer with water. The HVU uses a pump that pumps water through the cells for reasons beyond your question, but it also helps with cooling the electrolyer.

ABG: How do you plan to install the Electrolyzer in small cars of today where there is little extra space under the hood?

Owens: Firstly, the device is never installed under the hood. The space under the hood is too "unpredictable" from vehicle to vehicle, so we could never hope to have universal installation if we were even thinking about under the hood.

Secondly, we do not have any intention of installing the device in small cars (or even large cars for that matter...at least initially). In our testing, we discovered something I call "load sensitivity" in gasoline engines with what I would call "less than adequate" alternators. There is a limit to the amount load you can put on a vehicle and not have repercussions in terms of fuel economy. If the alternator has to work to hard to produce the hydrogen, there will be no gains in fuel economy. There may be some emission gains, but in the gasoline world, right now, the only thing that is important is fuel economy. For small cars....there is too much load even with our LVU.

Even though we did see a pretty good gain of fuel economy when we tested a 2010 Chevy Suburban (almost 24 percent on the highway test), there are a number of "variables" that can make the fuel economy gains in gasoline engines unpredictable or not consistent.

That is why our focus is on diesel engines, because the alternators (particularly for vehicles) are never as "sensitive" and particulate matter is a constant.

ABG: What additive do you use in water to make electrolysis possible?

Owens: There is no additive with the LeefH2. This is not alkaline electrolysis, where some type of additive is required, usually KOH, to cause the water to decompose to HHO.

We use PEM Electrolysis. PEM electrolysis is a different process altogether. There is no electrolytic solution. We only use deionized or distilled water. And instead of Oxyhydrogen or HHO being produced, we produce H2 and O2 as separate gas streams, where the H2 goes to the engine and the O2 goes to the environment. I cannot say this enough: this is not Alkaline Electrolysis. We do not produce HHO or Oxyhydrogen gas.

ABG: Has HNO been the recipient of government grants to promote this outstanding research? If yes then please list them along with dates and amounts.

Owens: No, we are in the process of hiring a grant writer so we can apply for government grants. The application for grant writing is a long process, and not as easy as most people would think.

ABG: How much oxygen and hydrogen does the Electrolyzer produce per hour?

Owens: The LVU (at least the seven-cell one, we have a 13-cell that we are testing), produces 0.230 liters per minute or 13.800 liters (.23 x 60) per hour of hydrogen

The HVU varies with the stack that we use. It can accommodate as few as four cells and as many as 40 in its present configuration. The HVU we are testing currently has six cells, which produces about 2.5 liters per minute or times 60 equals 150 liters of hydrogen per hour.

The electrolyzer is designed to produce hydrogen, so the the specs that we get from our supplier has to do with hydrogen production not oxygen production. Oxygen just happens to be a by-product.

However, in our testing, the LVU uses approximately an ounce of water every four hours or in 512 hours the LVU would have used about one gallon of water which is a little over seven pounds of oxygen. Per hour, this is roughly 0.0136 lbs per hour.

The HVU, as currently configured would use roughly one ounce of water every 24 minutes. In roughly 51 hours, this particular HVU would use roughly a gallon on water or a little over seven pounds of oxygen. Per hour, this is approximately 0.137 lbs per hour.

We have larger HVUs that will produce more oxygen for different applications and different engine sizes.

ABG: What is the efficiency of the HNO electrolysis unit?

Owens: We do not produce our electrolyzers, we get them from a supplier, so I do not know the exact efficiency numbers. PEM electrolyzers are known to be more efficient than Alkaline electrolyzers. According to a study from J. Electrochemical Society, "the initial performances [of PEM electrolysis] yielded 1.88 V at 1.0 A/cm2 which was, compared to the alkaline electrolysis technology of that time, very efficient." We use PEM electrolysis.

ABG: How does hydrogen increase the Laminar flame speed?

Owens: The question of the century. Hydrogen is known to have a flame speed that is much, much faster than typical fuels used in combustion engines. There is a demonstration of this (that we did not produce) on YouTube. It is very instructive relating to just the pure flame speed of hydrogen. Please review it for your own edification if you are not already aware of it. The explanation of Laminar Flame Speed will make more sense once you do.

Now that you have seen that, you can have a better understanding of the research that has been done on Hydrogen and Laminar flame speed. In studies at Princeton and MIT, hydrogen was shown to increase the Laminar flame speed and combustion efficiency. Because of the presence of hydrogen, the flame speed of diesel fuel (even natural gas) is increased. There even seems to be a linear relationship between the addition of hydrogen and the flame speed increase.

ABG: How much capital has been invested in HNO Green Fuels, Inc. so far?

Owens: We have "self funded" with friends and family. We are a private company and the amount that we have raise is confidential.

ABG: Bloomberg mentions HNO Green Fuels, Inc. filed for Private Placement on January 17, 2014. How is this proceeding? Have you raised funds or are you currently a public company?

Owens: We have not raised much with our private placement yet. We are still in the process of raising funds, and most has been through our personal network of friends and family.

We are not a public company.

===

Charlie Paglee is the CEO of Brannan Auto, an American automotive component engineering and manufacturing company focused on China, specifically on the electric vehicle industry. Mr. Paglee has more than two decades of business experience in China and speaks fluent Chinese Mandarin. Mr. Paglee is an electrical engineer who started working with electric vehicles in 1991. Mr. Paglee was the Vice President of China for Fisker Automotive and before that he was Employee Number 5 at Aptera Motors.

Turn your diesel engine into an oxygen farm? Really? LeefH2 supposedly works by breaking the water molecule up into hydrogen and oxygen, releasing oxygen into the atmosphere and then burning hydrogen in the fuel mixture. Except that when hydrogen is burned it bonds again with oxygen from the atmosphere, so the net oxygen produced by this scheme? Zero!

HNO harps on a strange claim in their promotional video:

This shows that HNO doesn't understand very basic science and might not be a company you want to be giving your money to. But they made a really slick video!If adopted worldwide we really could make particulate matter from diesel emissions a thing of the past, while adding billions of tons of life sustaining oxygen to the atmosphere.

The problem with the "scheme" is Newton's Third Law of Motion: For every action there is an equal but opposite reaction. Non-engineers sometime think electricity in a car is free, but producing electricity in a car increases the load on the engine, reduces fuel efficiency and actually costs about $0.50 per kWhr in a car: more than 4 times what electricity costs at home. Similar things have been tried by many, including a product announcement by the beloved Malcolm Bricklin which never came to market.

Automobiles are designed to produce enough electricity to run all the systems in the car simultaneously. When you add extra loads like an "electrolyzer," the alternator will burn out. So for this scheme to work the current must be kept very low. Except that hydrogen produced through electrolysis at 12V at a low current will have a very low efficiency: probably much less than 50 percent. This means it takes twice as much energy to produce the hydrogen than is produced when the hydrogen is burned, which wastes energy.

LeefH2 says that the efficiency of the diesel burn is so dramatically improved that it makes up for this loss in efficiency caused by producing the hydrogen. The idea is that hydrogen burns so quickly that it will make the diesel burn more thoroughly. Except that nobody can ever demonstrate that the improved diesel burn makes up for the loss in efficiency.

HNO's slick promotional video to get you to part with your money is also flat out wrong about clean diesel: advanced new technologies such as electronic controls, common rail fuel injection, variable injection timing, improved combustion chamber configuration and turbocharging definitely improve diesel combustion.

All internal combustion automobile engines (diesel and gasoline alike) today use electronic fuel injection controlled by a computer located somewhere in your car. Computer software controls how much fuel and air are combined based on a slew of variables to produce the most efficient burn possible. When hydrogen (which in this case is a fuel), normally not present in the air we breathe, is added to the engine air intake, the entire software to optimize the engine and reduce pollution is compromised. And unlike diesel or gasoline fuel which are precisely controlled by fuel injectors, the LeefH2 just allows hydrogen fuel to be added to the air intake without any regulation.

A group called Performance, Innovation, Transport investigated hydrogen injection claims (but not LeefH2 specifically, as far as we know), and writes in Hydrogen Injection: Myths and Facts that, "Contrary to manufacturer claims, none of these technologies has shown any ability to reduce vehicle fuel consumption."

Just like other contraptions which are supposed to reduce fuel consumption, if there was really something to the LeefH2 major automobile manufacturers would have implemented it a long time ago. If you want to lower fuel consumption and reduce emissions (and keep your money in your pocket) the US Department of Energy has some excellent suggestions you can follow which really do work.

So, those are my concerns with the LeefH2 technology. In the spirit of fairness, I asked a number of questions to HNO Fuels' Donald Owens. Owens has a mechanical-electrical engineering degree from Kettering University (formerly General Motors Institute) and a law degree from the Georgetown University Law Center.

===

ABG: What voltage does the HNO Electrolyzer use to perform electrolysis?

Owens: We have two different electrolyzer products. One is the LVU (Low volume unit) and the other is an HVU (High volume unit)

The LVU needs between 10.5 and 14 volts to operate. We are using PEM (Polymer Electrolyte Membrane) to accomplish the electrolysis of water. This particular cell/stack design uses two volts per cell and we are currently using a seven-cell stack in our LVU although we can add cells for application that may require a little more hydrogen than the current LVU produces, but not as much as what the HVU provides.

The HVU is a different cell/stack configuration and also requires 2 volts per cell, but the surface area of the cells are much larger and draws more current. Depending upon the configuration of the HVU (and hence the application), the voltage can be as low as eight to as high 30 for the applications we currently have in mind right now. However, the one we are testing has six cells and can operate on nine-to-12 volts.

ABG: How much current does the HNO Electrolyzer use?

Owens: The LVU uses from 3.5 to 5 amps. The HVU, as high as 40 - 50 amps.

ABG: Can the Electrolyzer be mounted on its side, or does it need to be facing upright to function?

Owens: The electrolyzer itself can be mounted on "its side" and still function, but in our application the water is "gravity fed" to our electrolyzers, hence the device itself (HVU or LVU) needs to be upright, if for no other reason for gravity to feed the electrolyzer with water. The HVU uses a pump that pumps water through the cells for reasons beyond your question, but it also helps with cooling the electrolyer.

ABG: How do you plan to install the Electrolyzer in small cars of today where there is little extra space under the hood?

Owens: Firstly, the device is never installed under the hood. The space under the hood is too "unpredictable" from vehicle to vehicle, so we could never hope to have universal installation if we were even thinking about under the hood.

Secondly, we do not have any intention of installing the device in small cars (or even large cars for that matter...at least initially). In our testing, we discovered something I call "load sensitivity" in gasoline engines with what I would call "less than adequate" alternators. There is a limit to the amount load you can put on a vehicle and not have repercussions in terms of fuel economy. If the alternator has to work to hard to produce the hydrogen, there will be no gains in fuel economy. There may be some emission gains, but in the gasoline world, right now, the only thing that is important is fuel economy. For small cars....there is too much load even with our LVU.

Even though we did see a pretty good gain of fuel economy when we tested a 2010 Chevy Suburban (almost 24 percent on the highway test), there are a number of "variables" that can make the fuel economy gains in gasoline engines unpredictable or not consistent.

That is why our focus is on diesel engines, because the alternators (particularly for vehicles) are never as "sensitive" and particulate matter is a constant.

ABG: What additive do you use in water to make electrolysis possible?

Owens: There is no additive with the LeefH2. This is not alkaline electrolysis, where some type of additive is required, usually KOH, to cause the water to decompose to HHO.

We use PEM Electrolysis. PEM electrolysis is a different process altogether. There is no electrolytic solution. We only use deionized or distilled water. And instead of Oxyhydrogen or HHO being produced, we produce H2 and O2 as separate gas streams, where the H2 goes to the engine and the O2 goes to the environment. I cannot say this enough: this is not Alkaline Electrolysis. We do not produce HHO or Oxyhydrogen gas.

ABG: Has HNO been the recipient of government grants to promote this outstanding research? If yes then please list them along with dates and amounts.

Owens: No, we are in the process of hiring a grant writer so we can apply for government grants. The application for grant writing is a long process, and not as easy as most people would think.

ABG: How much oxygen and hydrogen does the Electrolyzer produce per hour?

Owens: The LVU (at least the seven-cell one, we have a 13-cell that we are testing), produces 0.230 liters per minute or 13.800 liters (.23 x 60) per hour of hydrogen

The HVU varies with the stack that we use. It can accommodate as few as four cells and as many as 40 in its present configuration. The HVU we are testing currently has six cells, which produces about 2.5 liters per minute or times 60 equals 150 liters of hydrogen per hour.

The electrolyzer is designed to produce hydrogen, so the the specs that we get from our supplier has to do with hydrogen production not oxygen production. Oxygen just happens to be a by-product.

However, in our testing, the LVU uses approximately an ounce of water every four hours or in 512 hours the LVU would have used about one gallon of water which is a little over seven pounds of oxygen. Per hour, this is roughly 0.0136 lbs per hour.

The HVU, as currently configured would use roughly one ounce of water every 24 minutes. In roughly 51 hours, this particular HVU would use roughly a gallon on water or a little over seven pounds of oxygen. Per hour, this is approximately 0.137 lbs per hour.

We have larger HVUs that will produce more oxygen for different applications and different engine sizes.

ABG: What is the efficiency of the HNO electrolysis unit?

Owens: We do not produce our electrolyzers, we get them from a supplier, so I do not know the exact efficiency numbers. PEM electrolyzers are known to be more efficient than Alkaline electrolyzers. According to a study from J. Electrochemical Society, "the initial performances [of PEM electrolysis] yielded 1.88 V at 1.0 A/cm2 which was, compared to the alkaline electrolysis technology of that time, very efficient." We use PEM electrolysis.

ABG: How does hydrogen increase the Laminar flame speed?

Owens: The question of the century. Hydrogen is known to have a flame speed that is much, much faster than typical fuels used in combustion engines. There is a demonstration of this (that we did not produce) on YouTube. It is very instructive relating to just the pure flame speed of hydrogen. Please review it for your own edification if you are not already aware of it. The explanation of Laminar Flame Speed will make more sense once you do.

Now that you have seen that, you can have a better understanding of the research that has been done on Hydrogen and Laminar flame speed. In studies at Princeton and MIT, hydrogen was shown to increase the Laminar flame speed and combustion efficiency. Because of the presence of hydrogen, the flame speed of diesel fuel (even natural gas) is increased. There even seems to be a linear relationship between the addition of hydrogen and the flame speed increase.

ABG: How much capital has been invested in HNO Green Fuels, Inc. so far?

Owens: We have "self funded" with friends and family. We are a private company and the amount that we have raise is confidential.

ABG: Bloomberg mentions HNO Green Fuels, Inc. filed for Private Placement on January 17, 2014. How is this proceeding? Have you raised funds or are you currently a public company?

Owens: We have not raised much with our private placement yet. We are still in the process of raising funds, and most has been through our personal network of friends and family.

We are not a public company.

===

Charlie Paglee is the CEO of Brannan Auto, an American automotive component engineering and manufacturing company focused on China, specifically on the electric vehicle industry. Mr. Paglee has more than two decades of business experience in China and speaks fluent Chinese Mandarin. Mr. Paglee is an electrical engineer who started working with electric vehicles in 1991. Mr. Paglee was the Vice President of China for Fisker Automotive and before that he was Employee Number 5 at Aptera Motors.

Sign in to post

Please sign in to leave a comment.

Continue