The Environmental Protection Agency (EPA) is turning to a company whose home base is as old-school Rust Belt as one can get, but the company's specialty's undeniably new-school technology. The EPA has struck a deal with Pittsburgh-based ANSYS to model simulations of internal combustion engines. And while the models will be theoretical, the EPA is shooting for some very real results.

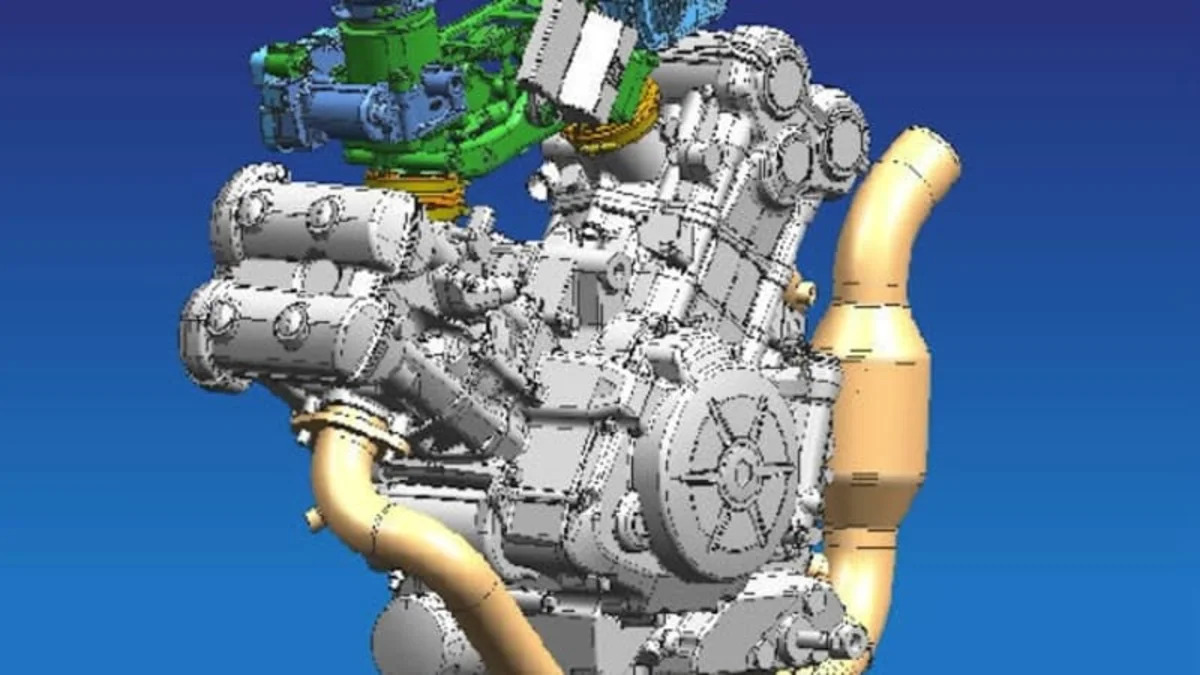

ANSYS, which employs more than 2,700 people and was founded in 1970, will model the inside of engines, with everything from chamber geometries to valve timing to fuel composition to fuel-injection methods being examined in order to find ways to eke out better fuel economy and lower greenhouse-gas emissions. The EPA will ultimately build a test engine based on the information gleaned from the three-dimensional simulation of the in-cylinder combustion process.

The process may not seem as sexy as battery-electric or hydrogen fuel-cell technology or even plug-in hybrid drivetrains. Still, the is EPA looking for improvements in light-duty vehicle engines to help cut fleetwide greenhouse gases in half between 2010 and 2025. And with internal combustion engines expecting to continue to account for the vast majority of car engines for the foreseeable future, these simulations may be valuable indeed. Check out ANSYS's press release below.

ANSYS, which employs more than 2,700 people and was founded in 1970, will model the inside of engines, with everything from chamber geometries to valve timing to fuel composition to fuel-injection methods being examined in order to find ways to eke out better fuel economy and lower greenhouse-gas emissions. The EPA will ultimately build a test engine based on the information gleaned from the three-dimensional simulation of the in-cylinder combustion process.

The process may not seem as sexy as battery-electric or hydrogen fuel-cell technology or even plug-in hybrid drivetrains. Still, the is EPA looking for improvements in light-duty vehicle engines to help cut fleetwide greenhouse gases in half between 2010 and 2025. And with internal combustion engines expecting to continue to account for the vast majority of car engines for the foreseeable future, these simulations may be valuable indeed. Check out ANSYS's press release below.

US Environmental Protection Agency Designs Test Engine With ANSYS Simulation Technology

PITTSBURGH, July 9, 2014 -- The U.S. Environmental Protection Agency (EPA) has selected ANSYS (NASDAQ: ANSS) simulation solutions to model in-cylinder combustion to develop an advanced test engine that will demonstrate fuel-saving and emissions-reducing technologies. The EPA's test engine will help establish the feasibility of meeting recently issued fuel standards through improvements to combustion chamber geometries, fuel injection strategies, fuel composition, valve timing and intake conditions.

While physical prototyping and direct tests on real engine hardware can guide engine design, they are very costly and time-intensive. By using ANSYS FORTE, the EPA can experiment with engine design in a virtual setting. As a result, its engineers can quickly and inexpensively make multiple design iterations. ANSYS acquired FORTE as part of its acquisition of Reaction Design earlier this year.

"The goal of our Clean Automotive Technology program is to research, evaluate and develop advanced engine and drivetrain technologies that help increase fuel efficiency, reduce regulated criteria emissions such as nitrogen oxides and particulate matter, and cut greenhouse gas emissions. To accomplish this, we needed to understand how changes in engine design and hardware can impact the engine combustion processes," said Matthew Spears, Heavy-Duty Onroad and Nonroad Center Director of EPA's Office of Transportation and Air Quality. "Using ANSYS solutions to generate realistic 3-D simulations of internal combustion engines, we can gain visibility into critical engine behaviors in a timely, cost-effective manner and obtain accurate and predictive results to guide the development of our test engine."

The new fuel standards are part of a joint final rule published by the EPA and the Department of Transportation's National Highway Traffic Safety administration (NHTSA). The new standards are designed to further reduce greenhouse gas emissions and improve fuel economy for model years 2017 through 2025 for light-duty vehicles. Combined with the previous EPA and NHTSA standards, the new program is projected to result in model year 2025 vehicles emitting one-half of the green gas emissions from the 2010 model year.

"Designing high performance internal combustion engines that meet regulatory mandates for reduced emissions is perhaps the top challenge faced by today's automotive manufacturers," said Bernie Rosenthal, general manager at ANSYS. "We are excited to support the EPA as the agency uses our computer simulation solutions to create its test engine. Reaction Design's fast, accurate and cost-effective modeling is critical to developing products that translate reliably to real-world functionality and lead to new advancements in engine and fuel technology."

In addition to gaining a better understanding of combustion dynamics through CFD modeling, the EPA intends to use ANSYS' detailed soot modeling capabilities to more accurately predict soot mass and particle size distribution, important metrics in the standards.

About ANSYS, Inc.

ANSYS brings clarity and insight to customers' most complex design challenges through fast, accurate and reliable engineering simulation. Our technology enables organizations ― no matter their industry ― to predict with confidence that their products will thrive in the real world. Customers trust our software to help ensure product integrity and drive business success through innovation. Founded in 1970, ANSYS employs more than 2700 professionals, many of them expert in engineering fields such as finite element analysis, computational fluid dynamics, electronics and electromagnetics, and design optimization.

Headquartered south of Pittsburgh, U.S.A., ANSYS has more than 75 strategic sales locations throughout the world with a network of channel partners in 40+ countries. Visit www.ansys.com for more information.

ANSYS also has a strong presence on the major social channels. To join the simulation conversation, please visit: www.ansys.com/Social@ANSYS

ANSYS and any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries. All other brand, product, service and feature names or trademarks are the property of their respective owners.

PITTSBURGH, July 9, 2014 -- The U.S. Environmental Protection Agency (EPA) has selected ANSYS (NASDAQ: ANSS) simulation solutions to model in-cylinder combustion to develop an advanced test engine that will demonstrate fuel-saving and emissions-reducing technologies. The EPA's test engine will help establish the feasibility of meeting recently issued fuel standards through improvements to combustion chamber geometries, fuel injection strategies, fuel composition, valve timing and intake conditions.

While physical prototyping and direct tests on real engine hardware can guide engine design, they are very costly and time-intensive. By using ANSYS FORTE, the EPA can experiment with engine design in a virtual setting. As a result, its engineers can quickly and inexpensively make multiple design iterations. ANSYS acquired FORTE as part of its acquisition of Reaction Design earlier this year.

"The goal of our Clean Automotive Technology program is to research, evaluate and develop advanced engine and drivetrain technologies that help increase fuel efficiency, reduce regulated criteria emissions such as nitrogen oxides and particulate matter, and cut greenhouse gas emissions. To accomplish this, we needed to understand how changes in engine design and hardware can impact the engine combustion processes," said Matthew Spears, Heavy-Duty Onroad and Nonroad Center Director of EPA's Office of Transportation and Air Quality. "Using ANSYS solutions to generate realistic 3-D simulations of internal combustion engines, we can gain visibility into critical engine behaviors in a timely, cost-effective manner and obtain accurate and predictive results to guide the development of our test engine."

The new fuel standards are part of a joint final rule published by the EPA and the Department of Transportation's National Highway Traffic Safety administration (NHTSA). The new standards are designed to further reduce greenhouse gas emissions and improve fuel economy for model years 2017 through 2025 for light-duty vehicles. Combined with the previous EPA and NHTSA standards, the new program is projected to result in model year 2025 vehicles emitting one-half of the green gas emissions from the 2010 model year.

"Designing high performance internal combustion engines that meet regulatory mandates for reduced emissions is perhaps the top challenge faced by today's automotive manufacturers," said Bernie Rosenthal, general manager at ANSYS. "We are excited to support the EPA as the agency uses our computer simulation solutions to create its test engine. Reaction Design's fast, accurate and cost-effective modeling is critical to developing products that translate reliably to real-world functionality and lead to new advancements in engine and fuel technology."

In addition to gaining a better understanding of combustion dynamics through CFD modeling, the EPA intends to use ANSYS' detailed soot modeling capabilities to more accurately predict soot mass and particle size distribution, important metrics in the standards.

About ANSYS, Inc.

ANSYS brings clarity and insight to customers' most complex design challenges through fast, accurate and reliable engineering simulation. Our technology enables organizations ― no matter their industry ― to predict with confidence that their products will thrive in the real world. Customers trust our software to help ensure product integrity and drive business success through innovation. Founded in 1970, ANSYS employs more than 2700 professionals, many of them expert in engineering fields such as finite element analysis, computational fluid dynamics, electronics and electromagnetics, and design optimization.

Headquartered south of Pittsburgh, U.S.A., ANSYS has more than 75 strategic sales locations throughout the world with a network of channel partners in 40+ countries. Visit www.ansys.com for more information.

ANSYS also has a strong presence on the major social channels. To join the simulation conversation, please visit: www.ansys.com/Social@ANSYS

ANSYS and any and all ANSYS, Inc. brand, product, service and feature names, logos and slogans are registered trademarks or trademarks of ANSYS, Inc. or its subsidiaries in the United States or other countries. All other brand, product, service and feature names or trademarks are the property of their respective owners.

Sign in to post

Please sign in to leave a comment.

Continue