Battery electric and plug-in hybrid electric vehicles with lithium-ion batteries are putting more and more odometer miles on every day. After two years on the market, some of these cars have up to 30,000 miles on them. That's good and all, but there's more to be done to prepare for the long term. General Motors, for example, tested the Chevrolet Spark EV batteries for over 200,000 hours. Ford, too, is looking way down the road, testing what life will be like for li-ion batteries after 10 years and 150,000 miles.

Ford set up a test lab, called the Key Life Test, to see what will happen to its new li-ion batteries. The company is also tapping into more than 20 years of company experience with hybrid electric vehicle batteries.

Ford engineers are simulating typical driving conditions that its electrified cars will be experiencing in coming years, including different temperature conditions and various acceleration and stopping styles. They are also testing how the location of the battery within a vehicle affects the pack. The scope of the testing allows Ford to put 150,000 test miles – roughly equivalent to 10 years for the average driver – on the batteries in about 10 months.

Ford's battery tests include simulating hot and sunny Phoenix weather by subjecting batteries to greater than 140-degree Fahrenheit temperatures, extreme cold conditions in Manitoba, Canada with frigid -40-degree Fahrenheit tests and by driving vehicles equipped with the batteries through ditches filled with water. As Nissan has learned, li-ion batteries driving in Arizona heat can raise the hackles of some electric car owners.

Ford says that out of the 50 million battery cells that were put into use in all Ford production models built to date, only six have failed. As more car buyers are shopping for electrified models and doing their homework, they'll probably be very interested in the results Ford learns from its Key Life Test. Ford's press release is available below.

• New Ford battery life validation protocol draws on two decades of electrified vehicle field experience to predict how lithium-ion (li-ion) batteries are likely to perform as far as 150,000 miles down the road

• Battery reliability has been identified as the top purchase consideration for potential customers, beating out other factors including fuel efficiency

• Ford is investing $135 million in the design, engineering and production of key components – including doubling its battery testing capabilities – for the five electrified vehicles it will offer by the end of the year

• Ford battery technology plays a key role in delivering class-leading fuel economy and range throughout its hybrid, plug-in hybrid and all-electric vehicle lineup

DEARBORN, Mich., Dec. 12, 2012 – Ford is putting the equivalent of 10 years and 150,000 miles of wear and tear on hybrid vehicle batteries using a new lab test that takes less than a year to complete.

Ford designed a new test – the Key Life Test – specifically for its new lithium-ion (li-ion) batteries, drawing on more than 20 years of extensive data and experience to deliver reliable hybrid vehicles today.

The test allows engineers to simulate in a lab setting many factors, including location of a battery within a vehicle, the temperatures they might have to endure, and various kinds of acceleration and stopping that different drivers would apply. The scope of the testing also includes the ability to put 150,000 miles (the equivalent of about 10 years of average use) on the test batteries in about 10 months.

The Key Life Test aims at delivering higher-quality and even more reliable batteries, said Kevin Layden, director of Ford Electrification Programs.

In fact, battery reliability ranks as the single-most important purchase consideration by potential hybrid customers – topping 17 other factors such as fuel economy and number of safety features, according to a recent Ford-commissioned survey.

"Recent studies show consumers are keeping their vehicles longer, and regulations in some regions now require batteries to carry warranties for greater distances," said Layden. "Fortunately, our tests take into account distances and conditions that go way beyond those normal requirements."

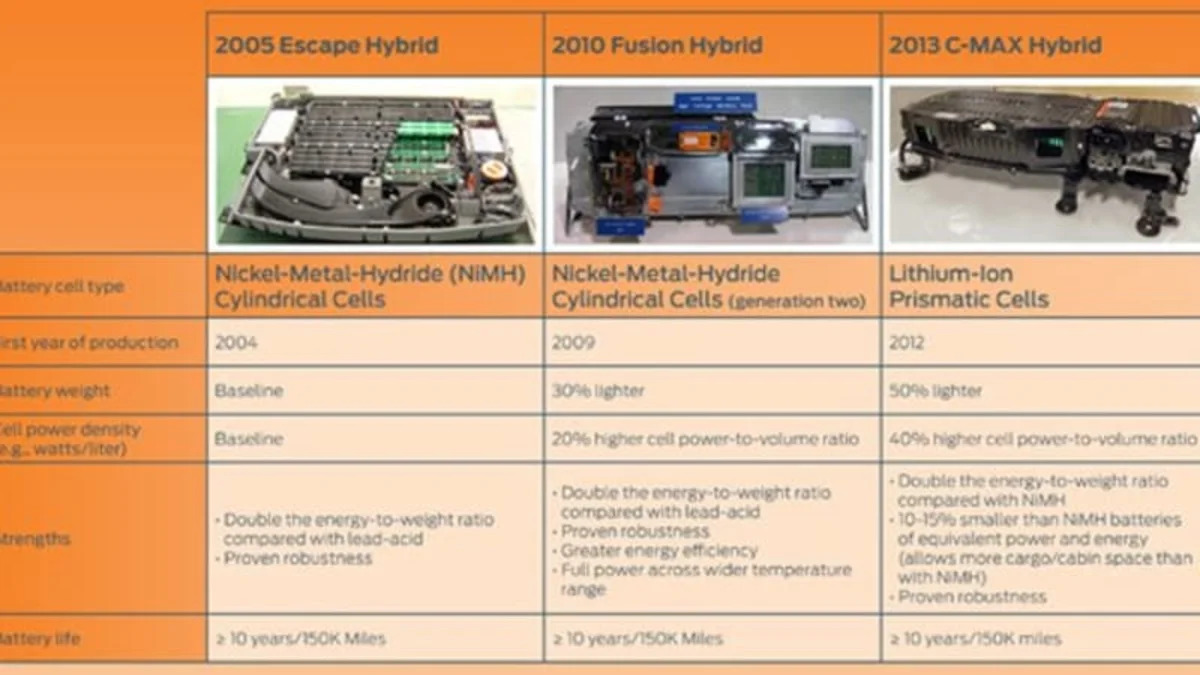

Ford will offer five electrified vehicles by 2013 – all equipped with advanced li-ion batteries. Previous-generation vehicles from Ford's lineup featured nickel-metal-hydride (NiMH) batteries. Li-ion batteries offer numerous benefits – including a size 25 to 30 percent smaller, and the ability to provide about three times the amount of power per cell than the previous state-of-the-art NiMH battery technology.

Other battery tests include simulating hot and sunny Phoenix weather by subjecting batteries to greater than 140-degree Fahrenheit temperatures, extreme cold conditions in Manitoba, Canada with frigid -40-degree Fahrenheit tests, and by driving vehicles equipped with the batteries through ditches filled with water to ensure there are no issues.

Ford's experience with hybrid vehicle technology dates back to the late 1980s. The technology evolved quickly, resulting in limited release of the Ranger EV in 1998, the Escape Hybrid in 2004 and the Fusion Hybrid in 2009. Ford draws on these vast amounts of data it collected from previous-generation hybrids.

For example, 50 million battery cells have been produced since 2004 in previous-generation production Ford hybrid vehicles such as the Escape Hybrid and Fusion Hybrid.

Some of these have been put to use in taxi fleets in such cities as San Francisco and New York, with some taxi vehicles attaining more than 250,000 miles individually and taxi fleets in California alone attaining a total of nearly 100 million miles.

The success rate is stellar: Of all Ford production hybrid vehicles produced to date, only six battery cells have failed of the 50 million that were put into use.

"We can't do an apples-to-apples comparison between the nickel-metal-hydride and lithium-ion batteries," says Mazen Hammoud, chief engineer, Electrified Powertrain Systems. "But we can evaluate much of the data collected to see how hybrid vehicles are driven, the kinds of conditions they face and the demands that are placed on them. Knowing all of that helps us benchmark our tests and ensure the lithium-ion batteries are meeting or exceeding expectations."

Going further

The Key Life Test represents just one aspect of Ford's commitment to deliver leading fuel economy across its lineup and triple electrified vehicle production capacity by 2013.

Ford is investing $135 million in the design, engineering and production of key components – including doubling its battery testing capabilities – for the five electrified vehicles the company will have in its portfolio by the end of the year: Fusion Hybrid, Fusion Energi plug-in hybrid, C-MAX Hybrid, C-MAX Energi plug-in hybrid and Focus Electric.

Ford also now has more than 1,000 engineers working on vehicle electrification, which is headquartered at its 285,000-square-foot Advanced Electrification Center in Dearborn.

The investment in people and infrastructure is already paying off: Ford has reduced the cost of its current hybrid system by 30 percent compared with previous-generation technology and vehicles are coming to market 25 percent faster.

More information about Ford's electrified vehicle lineup – including press releases, fact sheets, product sheets, technical specifications, photos and videos – can be found here - http://media.ford.com/mini_sites/10031/Electrification/

# # #

About Ford Motor Company

Ford Motor Company, a global automotive industry leader based in Dearborn, Mich., manufactures or distributes automobiles across six continents. With about 172,000 employees and 65 plants worldwide, the company's automotive brands include Ford and Lincoln. The company provides financial services through Ford Motor Credit Company. For more information regarding Ford and its products worldwide, please visit http://corporate.ford.com.

Ford set up a test lab, called the Key Life Test, to see what will happen to its new li-ion batteries. The company is also tapping into more than 20 years of company experience with hybrid electric vehicle batteries.

Ford engineers are simulating typical driving conditions that its electrified cars will be experiencing in coming years, including different temperature conditions and various acceleration and stopping styles. They are also testing how the location of the battery within a vehicle affects the pack. The scope of the testing allows Ford to put 150,000 test miles – roughly equivalent to 10 years for the average driver – on the batteries in about 10 months.

Battery reliability is the top purchase consideration for hybrid customers, topping 17 other factors including fuel economy and safety features, according to a recent Ford-commissioned survey. "Recent studies show consumers are keeping their vehicles longer, and regulations in some regions now require batteries to carry warranties for greater distances," said Kevin Layden, director of Ford Electrification Programs, in a statement (available below)."Recent studies show consumers are keeping their vehicles longer, and regulations ... now require batteries to carry warranties for greater distances."

Ford's battery tests include simulating hot and sunny Phoenix weather by subjecting batteries to greater than 140-degree Fahrenheit temperatures, extreme cold conditions in Manitoba, Canada with frigid -40-degree Fahrenheit tests and by driving vehicles equipped with the batteries through ditches filled with water. As Nissan has learned, li-ion batteries driving in Arizona heat can raise the hackles of some electric car owners.

By next year, Ford will have five models on the market with advanced li-ion batteries. Li-ion batteries are smaller and have the capacity to offer up three times the amount of power per cell than the NiMH batteries. The earliest versions of these batteries go back to the late 1980s for Ford, and were tested out in the Ford Ranger EV in 1998, and then in the Escape Hybrid in 2004 and the Fusion Hybrid in 2009.By next year, Ford will have five models on the market with advanced li-ion batteries.

Ford says that out of the 50 million battery cells that were put into use in all Ford production models built to date, only six have failed. As more car buyers are shopping for electrified models and doing their homework, they'll probably be very interested in the results Ford learns from its Key Life Test. Ford's press release is available below.

• New Ford battery life validation protocol draws on two decades of electrified vehicle field experience to predict how lithium-ion (li-ion) batteries are likely to perform as far as 150,000 miles down the road

• Battery reliability has been identified as the top purchase consideration for potential customers, beating out other factors including fuel efficiency

• Ford is investing $135 million in the design, engineering and production of key components – including doubling its battery testing capabilities – for the five electrified vehicles it will offer by the end of the year

• Ford battery technology plays a key role in delivering class-leading fuel economy and range throughout its hybrid, plug-in hybrid and all-electric vehicle lineup

DEARBORN, Mich., Dec. 12, 2012 – Ford is putting the equivalent of 10 years and 150,000 miles of wear and tear on hybrid vehicle batteries using a new lab test that takes less than a year to complete.

Ford designed a new test – the Key Life Test – specifically for its new lithium-ion (li-ion) batteries, drawing on more than 20 years of extensive data and experience to deliver reliable hybrid vehicles today.

The test allows engineers to simulate in a lab setting many factors, including location of a battery within a vehicle, the temperatures they might have to endure, and various kinds of acceleration and stopping that different drivers would apply. The scope of the testing also includes the ability to put 150,000 miles (the equivalent of about 10 years of average use) on the test batteries in about 10 months.

The Key Life Test aims at delivering higher-quality and even more reliable batteries, said Kevin Layden, director of Ford Electrification Programs.

In fact, battery reliability ranks as the single-most important purchase consideration by potential hybrid customers – topping 17 other factors such as fuel economy and number of safety features, according to a recent Ford-commissioned survey.

"Recent studies show consumers are keeping their vehicles longer, and regulations in some regions now require batteries to carry warranties for greater distances," said Layden. "Fortunately, our tests take into account distances and conditions that go way beyond those normal requirements."

Ford will offer five electrified vehicles by 2013 – all equipped with advanced li-ion batteries. Previous-generation vehicles from Ford's lineup featured nickel-metal-hydride (NiMH) batteries. Li-ion batteries offer numerous benefits – including a size 25 to 30 percent smaller, and the ability to provide about three times the amount of power per cell than the previous state-of-the-art NiMH battery technology.

Other battery tests include simulating hot and sunny Phoenix weather by subjecting batteries to greater than 140-degree Fahrenheit temperatures, extreme cold conditions in Manitoba, Canada with frigid -40-degree Fahrenheit tests, and by driving vehicles equipped with the batteries through ditches filled with water to ensure there are no issues.

Ford's experience with hybrid vehicle technology dates back to the late 1980s. The technology evolved quickly, resulting in limited release of the Ranger EV in 1998, the Escape Hybrid in 2004 and the Fusion Hybrid in 2009. Ford draws on these vast amounts of data it collected from previous-generation hybrids.

For example, 50 million battery cells have been produced since 2004 in previous-generation production Ford hybrid vehicles such as the Escape Hybrid and Fusion Hybrid.

Some of these have been put to use in taxi fleets in such cities as San Francisco and New York, with some taxi vehicles attaining more than 250,000 miles individually and taxi fleets in California alone attaining a total of nearly 100 million miles.

The success rate is stellar: Of all Ford production hybrid vehicles produced to date, only six battery cells have failed of the 50 million that were put into use.

"We can't do an apples-to-apples comparison between the nickel-metal-hydride and lithium-ion batteries," says Mazen Hammoud, chief engineer, Electrified Powertrain Systems. "But we can evaluate much of the data collected to see how hybrid vehicles are driven, the kinds of conditions they face and the demands that are placed on them. Knowing all of that helps us benchmark our tests and ensure the lithium-ion batteries are meeting or exceeding expectations."

Going further

The Key Life Test represents just one aspect of Ford's commitment to deliver leading fuel economy across its lineup and triple electrified vehicle production capacity by 2013.

Ford is investing $135 million in the design, engineering and production of key components – including doubling its battery testing capabilities – for the five electrified vehicles the company will have in its portfolio by the end of the year: Fusion Hybrid, Fusion Energi plug-in hybrid, C-MAX Hybrid, C-MAX Energi plug-in hybrid and Focus Electric.

Ford also now has more than 1,000 engineers working on vehicle electrification, which is headquartered at its 285,000-square-foot Advanced Electrification Center in Dearborn.

The investment in people and infrastructure is already paying off: Ford has reduced the cost of its current hybrid system by 30 percent compared with previous-generation technology and vehicles are coming to market 25 percent faster.

More information about Ford's electrified vehicle lineup – including press releases, fact sheets, product sheets, technical specifications, photos and videos – can be found here - http://media.ford.com/mini_sites/10031/Electrification/

# # #

About Ford Motor Company

Ford Motor Company, a global automotive industry leader based in Dearborn, Mich., manufactures or distributes automobiles across six continents. With about 172,000 employees and 65 plants worldwide, the company's automotive brands include Ford and Lincoln. The company provides financial services through Ford Motor Credit Company. For more information regarding Ford and its products worldwide, please visit http://corporate.ford.com.

Sign in to post

Please sign in to leave a comment.

Continue