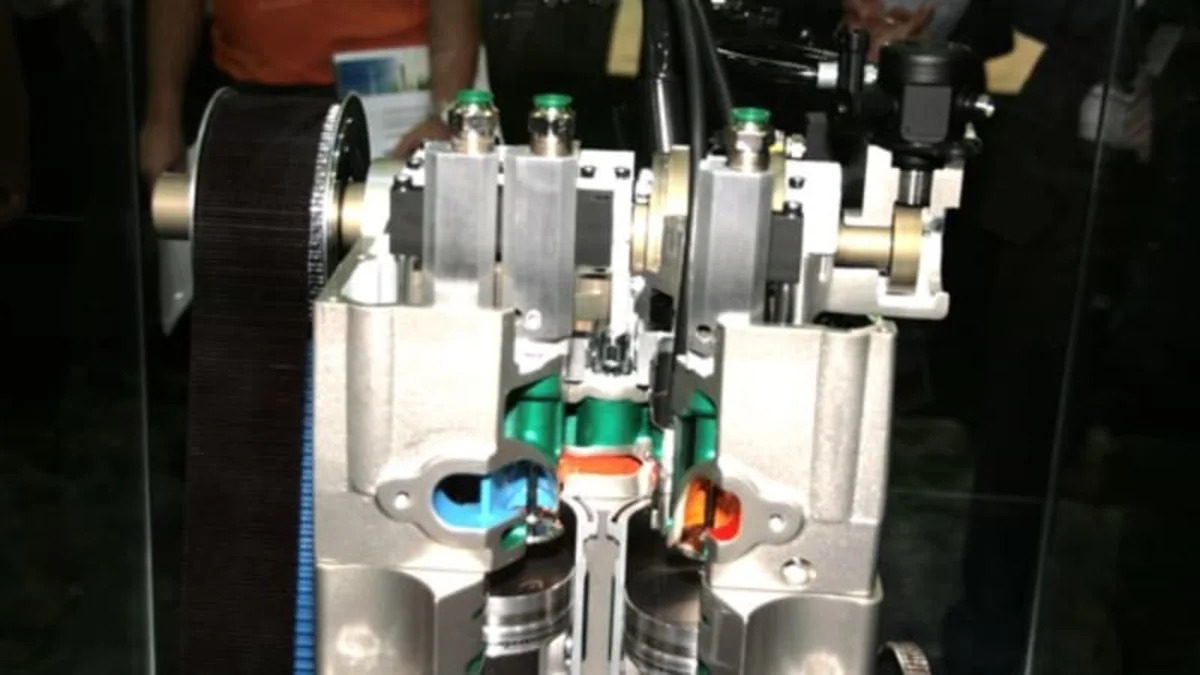

The Scuderi group unveiled a cutaway version of its first prototype of a new split cycle engine at the SAE World Congress this week. We first heard about this engine three years ago and got more details at the 2007 SAE WC, but this is the first time we have seen something physical rather than just CG animations. The first actual running prototype used to prove out the combustion process is being assembled right now and expected to start running by mid-May. It will be a normally aspirated variant with a displacement of 1.0-liter.

The engine uses pairs of pistons operating in parallel to split the typical 4-stroke cycle into pairs of two strokes. The first piston handles the intake and compression strokes with only air coming in. As a result, the air is compressed at a ratio of 100:1 before a crossover valve is opened allowing the compressed air to pass over to the power side. What happens next? Find out after the jump.

The engine uses pairs of pistons operating in parallel to split the typical 4-stroke cycle into pairs of two strokes. The first piston handles the intake and compression strokes with only air coming in. As a result, the air is compressed at a ratio of 100:1 before a crossover valve is opened allowing the compressed air to pass over to the power side. What happens next? Find out after the jump.

A pair of poppet valves manage the flow of compressed air to flow from the compression to the power cylinder. However, because of the high pressures being generated, approximately 50 BAR, Scuderi set the crossover valves to be outward opening (that is, they open away from the cylinder rather than into it). As the compressed air passes through the crossover, the shape of the passage and high pressure combine to induce more swirl. A Bosch-supplied injector of the same type used for direct injection systems sprays fuel into the cross over passage and the high pressure air causes it to mix more thoroughly than a conventional engine.

Scuderi believes that they can make this design work with the fuel being ignited after the power piston passes top dead center. Firing the spark plug after TDC prevents any re-compression of the expanding gases, raising the thermal efficiency compared to earlier split cycle engine designs. The cylinder pressure rises to about 65 BAR during ignition but drops as the piston moves down the cylinder. The result is that the combustion temperature actually drops at the same time, eliminating about 80 percent of NOx production.

%Video-451%

Scuderi claims the split cycle process will work with spark ignition as well as compression ignition diesel engines. The first prototype is normally aspirated and Scuderi expects it to get about same fuel efficiency as a similarly powerful conventional Otto cycle engine. The big advantage will be in emissions with dramatic reductions in NOx and HC.

Future variants will include turbocharged and air hybrid designs that will allow increased efficiency in addition to the lower emissions. The turbo version could produce up to 135 hp/liter allowing for a much smaller engine without compromising power output. Scuderi is also developing an air hybrid variant that adds a high pressure air accumulator to improve the efficiency of the engine to a level the company claims will be comparable to current gas-electric hybrids at much lower cost.

Speaking of cost, Scuderi claims that in spite of the new architecture, the split cycle engine will cost about the same as a conventional engine of similar output. A diesel version could conceivably significantly less expensive because the complex after-treatment systems could be scaled back or eliminated while still meeting emissions requirements. Scuderi claims to be talking to a number of automakers about licensing the technology and hopes to have a deal within a year to 18 months. Hopefully, a production engine based on this design will be on the road within 3-5 years.

Sign in to post

Please sign in to leave a comment.

Continue