Think CIty factory in Elkhart, IN – Click above for high-res image gallery

Turns out, 20 electric cars a day can make a huge difference.

That's how many vehicles Think is running through the production line at its new Elkhart, IN production facility right now as it ramps up for full production in the middle of next year. The vehicles are only being assembled here – the parts are all made elsewhere, like Finland and Turkey – and they are just the beginning of a big multi-year project to kickstart electric vehicle production in Indiana. We got to visit the plant yesterday afternoon and got a glimpse of Think's vision of how the empty space will grow to include local batteries and a more American-made product.

Think has invested $55 million in its Elkhart plant, which used to belong to an RV supplier, and the first employees started work there on October 4, 2010. Now, there are 27 employees working in 65,000 square feet. Think has 205,000 sq. ft. available in the facility and hopes to employ 400 people there, which shows just how large the company's plans are. Read on after the jump to find out how big. Oh, and to find out just how much one will cost and how far one can go (the details are a bit different than we thought).

Photos by Sebastian Blanco / Copyright ©2010 Weblogs, Inc.

Working in 10-hour shifts seven days a week, Think's tiny Elkhart crew will assemble 304 vehicles in 2010. Next year, the plan calls for 2,500 to be made – 1,000 of those will be "battery install" vehicles that will be used in different ways to shift the plant from simple assembly to actual production; 1,500 of those will be full production models, starting in July 2011. If 2,500 is not big enough for you, then know that the plant has an annual "theoretical capacity" of 60,000 vehicles if demand warrants it, said Think manufacturing director Karl Turner.

Could Think really sell 60,000 electric vehicles (EVs) a year? Not at first, but Think CEO Barry Engle told AutoblogGreen that his company's marketing strategy is different and is poised to target a lot of potential City drivers. After working on EVs for 19 years, Think knows who its customers are (and could be). Engle said he knows his company is selling a car designed for use in heavily-congested European cities and that the upcoming U.S. marketing efforts will most certainly be aimed at people who live in cities and people who commute in and out of them.

First, though, Think will focus on fleet sales. Then, in the middle of 2011, Think will open its first retail dealerships in the U.S., starting with three or four boutiques in places like California and New York. Oh, and Indianapolis, too, given the company's ties to the area. By end of 2011, Think hopes to have a half dozen shops open and, by 2012, it wants to be in the top 20 markets. By then, perhaps, sales of the City might be half fleet/ half residential.

How a Think City gets made today (and how this will change)

Right now, the "battery install" vehicles come partially assembled from Valmet on wooden skids (seen here). The skids are sent back to Finland while the cars are put together in Eklhard at about ten stations. The first station is where the EnerDel batteries, made nearby, are put in and the mandated TPMS system is put in. In later stations, the full interior, air conditioner, headlamps, seats and everything else is installed and checked for accuracy and safety. The EnerDel batteries arrive at Elkhart with a 40 percent state of charge, and the finished cars leave the plant full of juice. (You can read about how this system differs from Think's production line at Valmet in Finland here.)

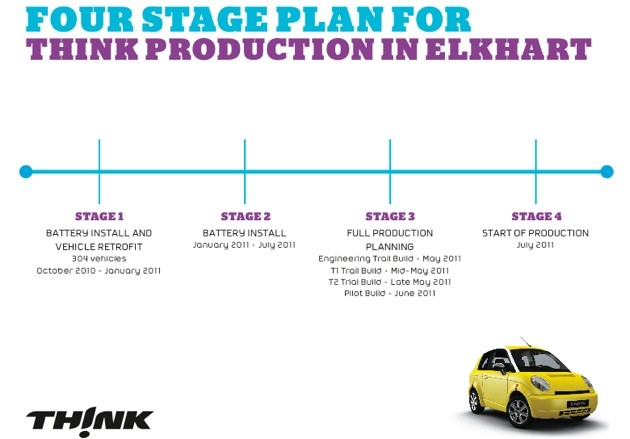

Over the next few months, though, Think will be expanding this assembly process at Elkhart according to the timeline pictured here as it moves to "full production."

- Stage 1– Battery Install, Vehicle Retrofit – 304 vehicles – October 2010-January 2011

- Stage 2 – Battery Install – Jan 11-July 11

- Stage 3 – Full Production Planning – in four sub-stages

- engineering trial build - May 2011

- 1st trial build - Mid-May 2011

- 2nd trial build - End of May 2011 (This includes line balancing and hiring more workers)

- Pilot build - end of June 2011 (This is where the plant get ready to go into full production.)

- State 4 - Start of Production – July 2011 will see the start of full vehicle production of 1,500 in 2011 (the first thousand for 2011 will be the battery install vehicles).

Think representatives say getting all these components from other companies means they are trading off lower investment costs for higher piece costs and that this can be a good thing. For example, the company can freshen the product more quickly. By the way, the next-gen City is supposed to debut in 2013.

Here are a few more important details about the car that will be sold in the U.S.:

It has a "100-mile range"

The City has a window sticker that has been okayed by the EPA and says the car has a range of 100 miles. Don't think this means the City can easily go further than the all-electric Nissan Leaf, which has an official EPA sticker range of 73 miles. Instead, Engle explained to AutoblogGreen, the EPA currently uses two different test cycles, one that the EPA will conduct for OEMs under a new test cycle that is not mandatory until 2012 and another, older test cycle that companies can use if they conduct it themselves and then submit the results to the EPA. "This is what we did," Engle said. "Our result is on a different drive cycle than the Leaf's. Their window sticker is under the new, 2012 cycle." Engle would not guess which number the City will get under the 2012 cycle, but did admit that, "It will obviously be less."

The MSRP is, well, what, exactly?

Walking through the plant, we could see vehicles that have a listed MSRP of $39,995. This is higher than the $34,000 cost we heard about just a month ago. Think spokesperson Brendan Prebo clarified to AutoblogGreen that:

So, it looks like the price is already dropping as production slowly. slowly ramps up. As production in Elkhart continues to expand – and the marketplace gets crowded with other, potentially cheaper options – we'll be watching to see where that number goes.The price [$34,000] that was quoted is our price for 2011. We plan to begin targeting retail customers next year in the second half of the year. The price on the window sticker [$39,995] is the price of the cars being built this year. All of which have been committed to customers already.

Photos by Sebastian Blanco / Copyright ©2010 Weblogs, Inc.

Our travel for this media event was provided by the manufacturer.

Sign in to post

Please sign in to leave a comment.

Continue