Not so long ago, it was common for automatic transmissions to be referred to as slushboxes, since that's how they often behaved. Rather than use a mechanical clutch, traditional automatic transmissions use a fluid coupling between the engine and the gear-sets to transmit drive torque. This provides some benefits, but isn't a perfect system.

Unless a mechanical clutch is worn out and slipping, it transfers nearly 100 percent of the torque that goes in. Automatics use a torque converter that consists of three main components: the pump, turbine and stator all within a cavity filled with hydraulic fluid. The pump is connected to the engine and, at lower speeds, it spins within the fluid without driving the turbine. As the engine speeds up, the slippage within the fluid increases and the turbine begins to rotate. This, in turn, drive the gears and the wheels. The stator increases the turbulence between the other two components providing a torque multiplication effect. There is generally no direct connection between the pump and turbine other than the fluid, which is why the efficiency is anywhere between zero and about 80 percent. All this removes a pedal, but it used to mean automatics got much worse mileage than manual transmission vehicles. Read on after the jump to find out what engineers have done to overcome this discrepancy.

In the last 25 years, there have been three major advances to automatic transmissions that have made the biggest difference in fuel economy gains: more gear ratios, lock-up torque converters and electronic controls. Lock-up converters incorporate a mechanical clutch that can hard-couple the pump and turbine when the vehicle is cruising with no transmission shifting. The clutch allows the torque converter to achieve near-100 percent efficiency. In recent years, engineers have also been able to utilize electronic controls to increase the proportion of time that the torque converter is locked, further increasing efficiency.

Those electronics have played a much bigger role than just controlling the torque converter clutch. Since the mid-1990s, engineers have integrated the management of the engine and transmission making the entire system work together. In combination with electronic throttle, spark and fuel control, engineers have been able to optimize how the engine behaves during shifts as well as during acceleration.

Since fuel efficiency is measured on standard driving cycles on a dynamometer, the engineers are able to calibrate how the throttle responds regardless of what the driver actually requests with the accelerator pedal. This way, actual vehicle response can be closer to the demands of the cycle so the transmission typically shifts at lower engine speeds. The increasing number of ratios – automatics have gone from three speeds in the early-1980s to six, seven and eight speeds today – has also allowed engineers to calibrate shift patterns that keep the engine closer to its most efficient speed regardless of vehicle speed.

Despite the mechanical efficiency advantages of manual transmissions, the transmission is controlled by the vagaries of the driver trying to follow the test protocol. The result is that in most cases, the automatic transmission can now match or beat the manual. Going forward, automatics are likely to improve even more as torque converter automatics are gradually supplanted by dual-clutch transmissions (DCT). Volkswagen was the first automaker to introduce DCTs in some of its European models in the mid-2000s under the brand name DSG (and S-Tronic in Audi vehicles). DCTs are now becoming increasingly common from companies like Ford, Porsche, Volvo and others.

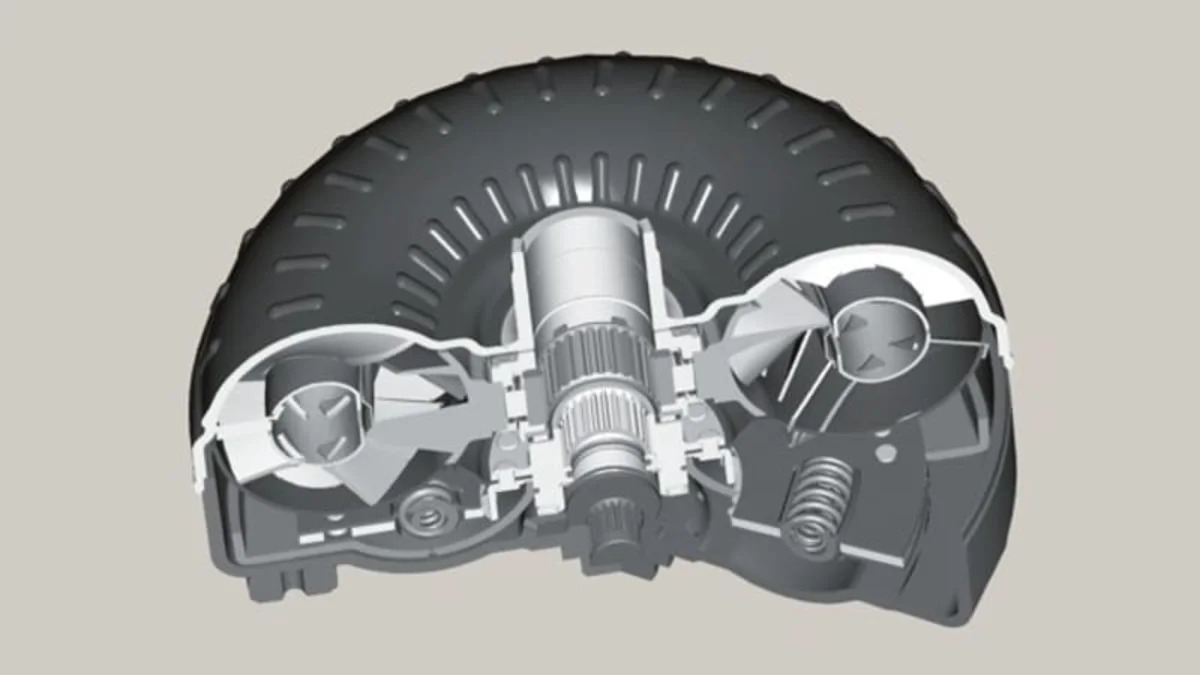

A DCT basically works like two manual transmissions in parallel, with one clutch engaging and disengaging for the odd numbered gears and the other for even numbered gears. As one engages the other disengages, the gear-set is shifted to the next one up or down. The use of mechanical clutches – like standard manuals have – makes the DCT more efficient and full electronic control lets the engineers make the same sort of optimizations they now do on torque converter automatics. The computers win again.

Unless a mechanical clutch is worn out and slipping, it transfers nearly 100 percent of the torque that goes in. Automatics use a torque converter that consists of three main components: the pump, turbine and stator all within a cavity filled with hydraulic fluid. The pump is connected to the engine and, at lower speeds, it spins within the fluid without driving the turbine. As the engine speeds up, the slippage within the fluid increases and the turbine begins to rotate. This, in turn, drive the gears and the wheels. The stator increases the turbulence between the other two components providing a torque multiplication effect. There is generally no direct connection between the pump and turbine other than the fluid, which is why the efficiency is anywhere between zero and about 80 percent. All this removes a pedal, but it used to mean automatics got much worse mileage than manual transmission vehicles. Read on after the jump to find out what engineers have done to overcome this discrepancy.

In the last 25 years, there have been three major advances to automatic transmissions that have made the biggest difference in fuel economy gains: more gear ratios, lock-up torque converters and electronic controls. Lock-up converters incorporate a mechanical clutch that can hard-couple the pump and turbine when the vehicle is cruising with no transmission shifting. The clutch allows the torque converter to achieve near-100 percent efficiency. In recent years, engineers have also been able to utilize electronic controls to increase the proportion of time that the torque converter is locked, further increasing efficiency.

Those electronics have played a much bigger role than just controlling the torque converter clutch. Since the mid-1990s, engineers have integrated the management of the engine and transmission making the entire system work together. In combination with electronic throttle, spark and fuel control, engineers have been able to optimize how the engine behaves during shifts as well as during acceleration.

Since fuel efficiency is measured on standard driving cycles on a dynamometer, the engineers are able to calibrate how the throttle responds regardless of what the driver actually requests with the accelerator pedal. This way, actual vehicle response can be closer to the demands of the cycle so the transmission typically shifts at lower engine speeds. The increasing number of ratios – automatics have gone from three speeds in the early-1980s to six, seven and eight speeds today – has also allowed engineers to calibrate shift patterns that keep the engine closer to its most efficient speed regardless of vehicle speed.

Despite the mechanical efficiency advantages of manual transmissions, the transmission is controlled by the vagaries of the driver trying to follow the test protocol. The result is that in most cases, the automatic transmission can now match or beat the manual. Going forward, automatics are likely to improve even more as torque converter automatics are gradually supplanted by dual-clutch transmissions (DCT). Volkswagen was the first automaker to introduce DCTs in some of its European models in the mid-2000s under the brand name DSG (and S-Tronic in Audi vehicles). DCTs are now becoming increasingly common from companies like Ford, Porsche, Volvo and others.

A DCT basically works like two manual transmissions in parallel, with one clutch engaging and disengaging for the odd numbered gears and the other for even numbered gears. As one engages the other disengages, the gear-set is shifted to the next one up or down. The use of mechanical clutches – like standard manuals have – makes the DCT more efficient and full electronic control lets the engineers make the same sort of optimizations they now do on torque converter automatics. The computers win again.

Sign in to post

Please sign in to leave a comment.

Continue