Click to enlarge

Hyundai has joined the "Blue is the new green movement" at the LA Auto Show, where the Korean automaker has announced its "Blue Drive" efficiency strategy. The core of the plan is meet the federally-mandated 35 mpg fleet average economy requirement by 2015 rather than the 2020 date specified in last year's energy bill. Hyundai has been in the top three along with Honda and Toyota for CAFE performance for several years now and intends to stay at the top of the list. The company plans to use a number technologies to achieve that goal including an in-house developed hybrid drive system that will debut on the next Sonata in 2010.

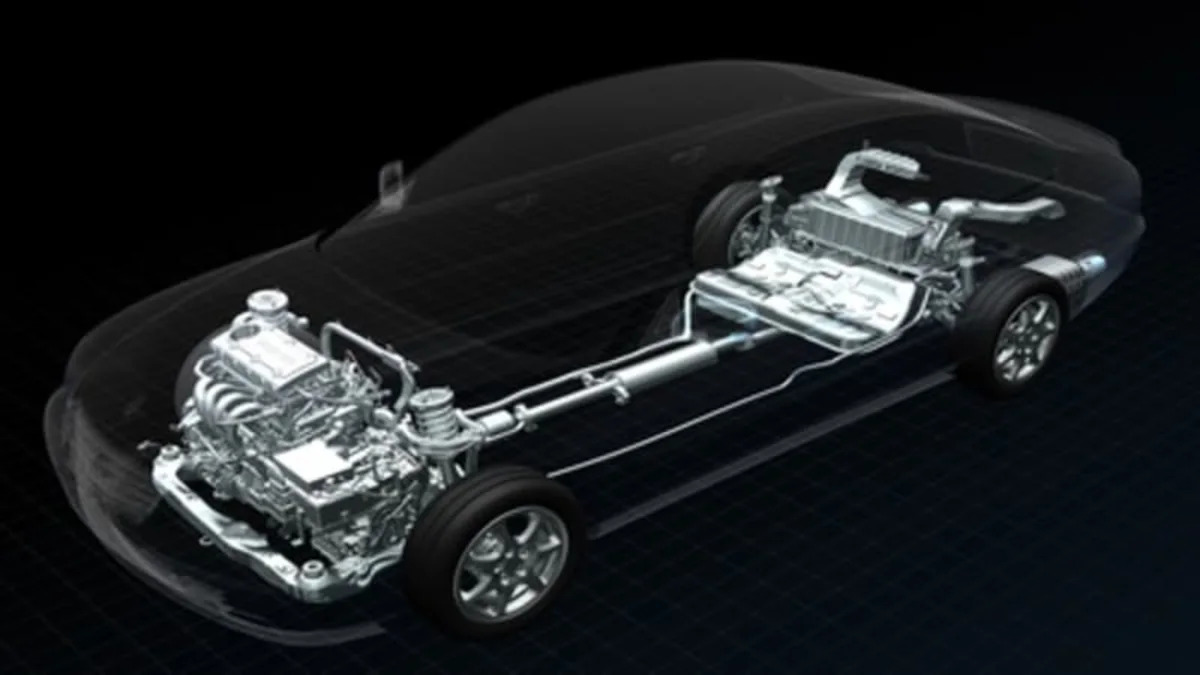

We had expected to see a prototype Sonata hybrid in LA, but instead Hyundai is just showing off the drive system that will go in the redesigned car. Hybrid Blue Drive integrates a 30 kW / 151 lb-ft motor/generator into the six-speed automatic transmission. The three lowest gears of the transmission have taller ratios than the conventional gearbox so that the engine is running at lower speed. The electric motor will make up for the reduced mechanical advantage of the new ratios. Learn more about Hyundai's plans after the jump.

[Source: Hyundai]

Hyundai has decided to follow a different path with the battery for its hybrid. Instead of the usual nickel metal hydride or even lithium ion, the company is going with lithium polymer. A hybrid version of the Elantra will debut in Korea in 2009 using this battery technology. For the US market Sonata, the battery will have a 1.4 kWh capacity. Hyundai is claiming the lithium polymer battery has better energy density than current lithium ion types. The packaging of the new battery with its flat cells will certainly be more efficient than those that use cylindrical cells like the Tesla battery.

The lithium polymer battery is also claimed to have better performance than nickel batteries over a wider temperature range which should help to improve hybrid efficiency in cold weather conditions. LG Chem, the company believed to have been chosen to supply the battery for the Chevy Volt is supplying Hyundai's batteries. Eventually the company also plans to add plug-in capability to its hybrids. The use of these lithium polymer batteries should give Hyundai a head start on adding plug-in capability since they won't have to transition to a completely different technology.

In addition to the hybrid drive, Hyundai is also optimizing other aspects of the new Sonata including the engine, weight and aerodynamics. The next generation Theta II 2.4L gets features like an electric oil pump and power steering assist, and reduced friction throughout the engine.

Before the Sonata hybrid arrives, we'll get "blue" editions of the Accent and Elantra in 2009. Both of these will be targeted at getting better fuel economy without having to pay a premium price. The cars will get low rolling resistance tires, taller final drive ratios, new engine calibrations and some aerodynamic tweaks. Hyundai says the "Blue" editions will get a lower price than current models which means they will probably be de-contented a bit.

Earlier this year, the HED-5 crossover concept appeared with a 2.0L turbocharged and direct injected four cylinder (GTDI) with 286 hp. The same engine also appeared in the Kia Koup concept at the New York Auto Show. Hyundai (and presumably Kia) will be introducing downsized four cylinder engines with GTDI to a variety vehicles in the next few years to help meet that 35 mpg fleet average.

Hyundai also plans to start low-volume series production of a fuel cell vehicle in Korea in 2012 using its own internally developed fourth-generation fuel cell stack.

PRESS RELEASE:

HYUNDAI BLUE DRIVE: A STRATEGY FOR ENVIRONMENTAL LEADERSHIP

Hyundai's First U.S. Hybrid System Uses Breakthrough Lithium Polymer Batteries and Leapfrogs Existing Nickel-Metal Hydride and Lithium-Ion Technology

LOS ANGELES, Nov. 19, 2008 – Hyundai Motor America announced today the launch of Blue Drive an environmental initiative which will bring to market a family of eco-friendly Blue Drive products and establish Hyundai as an environmental leader. With Blue Drive products and technologies, Hyundai will be able to achieve a fleet average of 35 miles per gallon by 2015, five years ahead of government requirements. During a news conference at the Los Angeles Auto Show, the company revealed plans for its first U.S.-market gas-electric full hybrid (to be offered in the next-generation Sonata), introduced a sleek crossover concept powered by a turbocharged gasoline direct injection (GDI) engine, and announced future high-mileage editions of the Accent and Elantra, underscoring its global commitment to sustainable transportation.

Blue Drive At-a-Glance

Hyundai plans to lead all automotive brands in the U.S. in fuel economy by achieving a fleet average of 35 miles per gallon by 2015, five years ahead of the National Highway Traffic Safety Administration's (NHTSA) deadline, powered by the Hyundai Blue Drive global product strategy.

Hyundai will begin building a gas-electric full hybrid edition of the next-generation Sonata for the North American market in 2010. This Sonata will use a parallel hybrid drive system and lithium polymer battery technology – leapfrogging competitive in-market nickel-metal hydride and planned lithium-ion applications.

Near-term, high mileage "Blue" editions of Accent and Elantra will join the Hyundai Blue Drive family in 2009.

An all-new crossover, shown in concept form with a 2.0-liter Theta turbocharged GDI four-cylinder engine, is green lighted for the U.S. market. The engine will appear in various Hyundai models in the future.

Long-term, the Hyundai Blue Drive family will be expanded to include Plug-in Hybrid Electric Vehicles (PHEV) and Fuel Cell Electric Vehicles (FCEV).

"Hyundai aims to be the most fuel-efficient automaker on the planet," said John Krafcik, vice president, Product Development and Strategic Planning, Hyundai Motor America. "We're aligning our global R&D resources in Michigan, California, Nam Yang, and Frankfurt to develop the Blue Drive technologies we need to achieve our goal – a 35 mpg U.S. fleet average by 2015."

HYUNDAI'S HYBRID BLUE DRIVE ARCHITECTURE

An all-new, homegrown hybrid architecture is at the heart of the Hyundai Blue Drive strategy. Hyundai's proprietary parallel hybrid drive system mates the already fuel efficient 2.4-liter Theta II engine to a 6-speed automatic transmission and a 30kW (205 N-m) electric motor for maximum fuel economy. Hybrid Blue Drive has an all-electric mode and a parallel drive mode. This means the wheels are turned by power coming directly from the gasoline engine, or the electric motor, or both together, as conditions demand. This parallel hybrid drive architecture will serve as the foundation for future hybrid drive vehicles to be developed by Hyundai, starting with the next-generation Sonata in the United States.

To maximize fuel economy, all of the Theta II major driveline and cooling system components have been optimized to reduce friction, while the crankcase has been filled with low friction oil. Engine management software automatically shuts off the engine when the vehicle comes to a halt, cutting emissions to zero. When pressure is reapplied to the accelerator pedal, the Integrated Starter Generator (ISG) automatically restarts the engine. The Theta II's engine management software governing injection pressure, engine cycle timing and exhaust retreatment rates has been revised to further reduce fuel consumption. This control strategy assures that maximum efficiency is achieved during gentle acceleration and greater power is immediately available during full acceleration. During deceleration, braking regeneration comes into play.

In addition, the top three gear ratios in the transmission have been extended to ensure the engine runs at lower RPMs, the latest electric motor-assisted steering system reduces power drain and low resistance tires further optimize fuel economy.

EMBED PowerPoint.Slide.8

Hybrid Blue Drive is made up of nine major components:

An efficient 30kW electric motor delivering 205 N-m of torque

A regenerative braking system

An integrated starter generator that enables the engine to turn off at stops and restart automatically under acceleration

A breakthrough lithium polymer battery package, with 5.3 Ah of capacity at 270 volts

Optimized Theta II 2.4-liter engine

6-speed automatic transmission with an improved efficiency electric oil pump

Weight-efficient architecture coupled with a low drag coefficient

Electric air conditioning compressor

Hybrid power control unit

LITHIUM POLYMER BATTERY TECHNOLOGY

Hyundai's hybrid system stores its electrical charge in a 270V lithium polymer rechargeable battery (5.3Ah/270V) that surpasses existing nickel-metal hydride and pending lithium-ion applications. Lithium polymer batteries are more durable and space-efficient than other hybrid batteries.

Lithium Polymer Batteries vs. Nickel-Metal Hydride Batteries

Compared with nickel-metal hydride batteries, lithium polymer batteries deliver the same power with 30 percent less weight, 50 percent less volume and 10 percent greater efficiency over the nickel-metal hydride batteries found in all of today's hybrids. Lithium polymer batteries offer more than twice the energy density of nickel-metal hydride batteries, and 175 percent greater volumetric energy density, meaning Hyundai engineers can devote less space and weight to the battery pack. Lithium polymer batteries also hold their charge 20 times longer. Lithium polymer batteries also are more resistant to changes in temperature, which improves cycle life. And lithium polymer's self-discharge rate is less than a third of a nickel-metal hydride battery.

Lithium Polymer Batteries vs. Lithium-ion Batteries

Lithium-polymer has significant advantages over lithium-ion batteries, including higher energy density and lower manufacturing costs. Lithium polymer is more resistant to physical damage and can handle more charge-discharge cycles before storage capacity begins to degrade. Lithium polymer technology also offers significant advantages in thermal robustness and safety compared with typical lithium-ion batteries.

A key difference between traditional lithium ion batteries and Hyundai's lithium polymer battery solution is the overall packaging of the cell – the anode, the cathode, the electrolyte, and the encasement material. Traditional lithium-ion batteries, like those found in laptops, use what's known as the 18650 cell format. In this format each mass-produced cell is 18 mm. in diameter and 65 mm. tall, which is a bit larger than a AA battery. Each of these small metal cylinders is filled with a liquid electrolyte which facilitates the movement of lithium ions across anode and cathode, creating the battery current.

Traditional lithium-ion batteries are easy to handle, can withstand mild internal pressures, and have been around in various forms since 1991. That means a manufacturing infrastructure is in place, and scale economies are reasonably high. However, they do have several disadvantages. For example, their cylindrical shape reduces packaging efficiency and they are surprisingly complicated to manufacture since they have so many small parts. These small parts make them robust to thermal fluctuations and add significant cost and weight to the overall battery system. Cell-to-cell consistency also is extremely critical in a vehicle battery package, since the pack is only as robust as its weakest cell. Traditional lithium-ion batteries have considerable cell-to-cell variation, while Hyundai's lithium polymer batteries deliver outstanding cell-to-cell consistency.

Lithium polymer technology uses a completely different approach. Rather than using a liquid electrolyte, which requires a robust metal casing, lithium polymer batteries use a polymer gel as the electrolyte, which allows the use of a thinner and lighter aluminum-walled encasement, or pouch. Inside each lithium polymer cell the cathode, separator, and anode are laminated together, enabling much simpler and more reliable manufacturing. This allows the battery pack to be about 20 percent smaller than a lithium-ion battery pack, making it much easier to change the cell footprint to fit the nooks and crannies of available vehicle space.

Hyundai has spent hundreds of hours testing Hybrid Blue Drive's lithium polymer battery system with its battery supplier, LG Chem. This testing has proven that Hyundai's lithium polymer technology has greater thermal and mechanical stability than existing systems, meaning better safety.

Another key engineering challenge for Hybrid Blue Drive has been assuring maintenance-free battery operation over the vehicle's life – at least 10 years, and 150,000 miles – in all weather conditions. Heat is the enemy of battery cycle life. Hyundai's thermal imaging testing shows how much cooler a lithium polymer battery is compared to today's nickel-metal hydride battery or a conventional lithium-ion battery. Consumers will notice these advantages in improved useful life and lower maintenance costs.

EMBED PowerPoint.Slide.8

OTHER ASPECTS OF HYUNDAI BLUE DRIVE – WEIGHT EFFICIENCY, TURBO GDI, OPTIMIZED BLUE MODELS, AND FUEL CELL ELECTRIC VEHICLES

HED-5 i-Mode Concept Vehicle

At the Geneva International Motor Show, Hyundai introduced the revolutionary HED-5 "i-Mode" concept car. Today, Hyundai Motor America is announcing that a production version of this compact, spacious, weight-efficient four-cylinder crossover has been green lighted for the U.S., with timing to be announced at a later date.

Turbocharged Gasoline Direct Injection Technology

The HED-5 concept was shown with an advanced 2.0-liter Theta turbocharged gasoline direct injection (GDI) four-cylinder engine capable of developing as much as 286 horsepower, and delivering more than 30 highway miles per gallon. This engine will appear in various Hyundai models in the future.

By injecting the fuel directly inside the cylinder in a small, precise amount, combustion is improved resulting in higher fuel efficiency and lower exhaust emissions. The performance and response of the engine also improves thanks to intake charge cooling. When direct injection is combined with turbo charging, customers enjoy even better performance and fewer trips to the gas station. Four-cylinder turbocharged gasoline direction injection engines can be 15 – 20 percent more fuel efficient than V6 engines without compromising performance.

Blue Editions

Next year, Hyundai will introduce high mileage "Blue" editions of its Accent and Elantra models. These models will deliver outstanding fuel economy without adding thousands of dollars to the price. In fact, "Blue" models will be priced lower than other models, assuring they will be both efficient and economical.

Hyundai is focused on achieving an excellent MPG-per-dollar ratio with these models. Fuel-efficient modifications include low-rolling-resistance tires, enhanced aerodynamics, revised engine calibrations and reduced final drive ratios to deliver even higher mileage and lower emissions than today's models. These new high mileage editions will be identified with unique "Blue" badging.

Blue Drive Hydrogen Fuel Cell Electric Vehicle

Hyundai is at the forefront of advanced technology research. In September 2005, Hyundai Motor Company celebrated the grand opening of its Eco-Technology Research Institute in Mabuk, Korea, which houses all R&D on environmentally friendly technologies, concentrating Hyundai's efforts to develop alternative powertrains in one state-of-the-art facility.

The ultimate expression of Hyundai Blue Drive TM is the hydrogen-powered Fuel Cell Electric Vehicle, the most promising technology for future transportation. Hyundai is participating in fuel cell verification programs around the world. In the United States, Hyundai has been a member of the California Fuel Cell Partnership (CaFCP) since 2000. The CaFCP is a collaboration of 33 member organizations, including auto manufacturers, energy providers, government agencies and fuel cell technology companies, that work together to promote the commercialization of hydrogen fuel cell vehicles.

In 2004, Hyundai began a partnership with Chevron Corp. and UTC Power to initiate a 32-vehicle fleet testing program. This five-year cost-sharing program is sponsored by the United States Department of Energy.

Hyundai recently celebrated the successful completion of a 13-day, cross-country road trip that served as the first significant U.S. test for the company's proprietary fuel cell technology. The Tucson Fuel Cell Electric Vehicle (FCEV) on display in the Hyundai booth completed a 4,300 mile journey as part of the Hydrogen Road Tour 2008. Nine auto manufacturers, the U.S. Department of Energy, the California Fuel Cell Partnership, National Hydrogen Association and U.S. Department of Transportation sponsored and participated in the event.

Hyundai is making good progress toward meeting its goal of putting a Hyundai Blue Drive TM Hydrogen Fuel Cell Electric Vehicle in series production as early as 2012.

HYUNDAI MOTOR AMERICA

Hyundai Motor America, headquartered in Fountain Valley, Calif., is a subsidiary of Hyundai Motor Co. of Korea. Hyundai vehicles are distributed throughout the United States by Hyundai Motor America and are sold and serviced through almost 800 dealerships nationwide.

Sign in to post

Please sign in to leave a comment.

Continue