BMW's twin-turbo 3.0L inline-six has been a rousing success, with nothing less than a Wards 10 Best Engines award sitting in its trophy case. The praise is understandable and well-deserved, as the engine uses a combination of forced induction and direct injection to serve up a torque curve that's far beefier and flatter than what should be expected from a engine of its size. So what next for the propeller brand? Simple -- take similar technology, add it to the company's 4.4L V8 and toss in a dash of unconventional packaging to make everything fit.

BMW put its latest jewel on display at the 2008 Detroit Auto Show, and we snapped some shots of it to give you an idea of why this engine is so special. We've included those photos in one of our galleries, and below the fold, we've thrown in a few observations.

BMW put its latest jewel on display at the 2008 Detroit Auto Show, and we snapped some shots of it to give you an idea of why this engine is so special. We've included those photos in one of our galleries, and below the fold, we've thrown in a few observations.

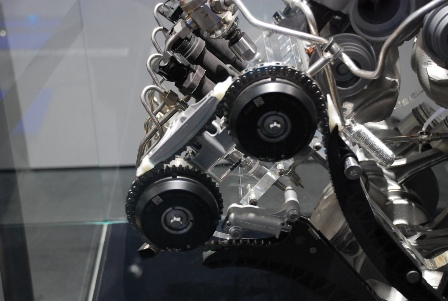

Undoubtedly, the most unique feature of the 4.4L TT is the packaging of the turbochargers in the valley between the cylinder banks.

This is made possible by the swapping of the intake and exhaust ports in the cylinder heads, with the exhaust now exiting towards the middle. This allows the turbochargers to be mounted in the valley with minimal plumbing, which means less bulk, lower weight and better efficiency.

Immediately after exiting the turbochargers, the exhaust gases enter the catalysts. It's important to keep the cats as close as possible, as the exhaust carries heat that is required for the converters' operation.

Packaging the cats in this location underneath the hood must present some interesting insulation challenges!

Instead of expensive variable-vane technology, each turbo makes use of fixed geometry and relatively simple wastegates.

Each compressor is fed via a black oval-shaped duct, as shown above.

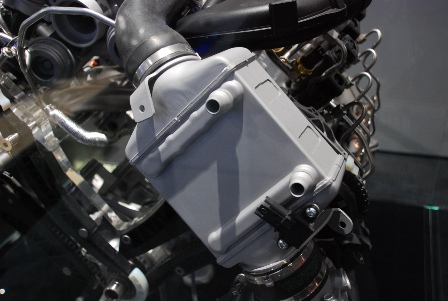

Between the compressor outlet and the intake manifolds lie a pair of air-to-water intercoolers, one for each bank. Such an intercooler reduces packaging volume and tract length compared to a top- or front-mounted air-to-air heat exchanger.

Immediately downstream of the intercoolers lie a pair of electronically-controlled throttle bodies.

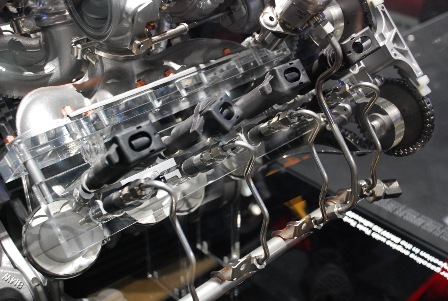

Below each centrally-located coil-on-plug (COP) assembly resides the direct injector, along with the feed lines and fuel rail. It's presumed that piezoelectric injectors are employed here, which are fast enough to allow several injection events per combustion cycle.

Each fuel rail gets its own fuel-pressure regulator. The operating system of this system is yet unknown, but we're guessing that it's similar to the 200 bar (3000 PSI) that is used in the engine's direct-injection predecessors.

Dished pistons are used to lower the compression ratio, with a compact ring package to reduce crevice volume and frictional losses.

The net effect is a peak of 400 HP, with 450 lb-ft of torque delivered between 1750 and 4500 RPM. In a sport sedan such as the 5 Series, this engine will likely erase fond memories of the musclecar era, and even in portly SUVs such as BMW's X5 and X6, the result should still be rather impressive.

Sign in to post

Please sign in to leave a comment.

Continue