All-wheel drive system supplier Haldex has introduced its latest iteration in the new Saab Turbo X and 9-3 Aero XWD vehicles. XWD strands for Cross-Wheel-Drive and is technically called Haldex version 4.0. Its introduction has generated some excitement amongst general consumers and tuning enthusiasts. Haldex has been riding the high wave with their XWD release as it was recently reported that they won a contract to develop a system for Hyundai. We have yet to see the new all-wheel-drive offering hit consumers in order to better understand its potential under extensive abuse though. However, the wonder that is YouTube has provided us with video of the Saab Aero XWD in action during a Saab comparison test drive event. Haldex has also supplied a wealth of information detailing the elements of their 4.0 system.

The main components of the new Haldex system are the Power Take-Off Unit (PTU), Limited Slip Coupling (LSC) and eLSD (Electronic Limited Slip Differential). The PTU is the final drive unit at the front of the vehicle that transmits power to the front wheels and sends power down the driveshaft to the rear wheels. It is not a Haldex design, but is required to adapt the system to a front-wheel drive vehicle. The LSC sits at the rear of the vehicle in-line with the driveshaft. It controls the torque split between the front and rear wheels of the vehicle. The LSC sends torque to the eLSD that sits between the rear wheels. The eLSD transfers torque to the two rear wheels. Follow the jump to continue reading more about the system.

The main components of the new Haldex system are the Power Take-Off Unit (PTU), Limited Slip Coupling (LSC) and eLSD (Electronic Limited Slip Differential). The PTU is the final drive unit at the front of the vehicle that transmits power to the front wheels and sends power down the driveshaft to the rear wheels. It is not a Haldex design, but is required to adapt the system to a front-wheel drive vehicle. The LSC sits at the rear of the vehicle in-line with the driveshaft. It controls the torque split between the front and rear wheels of the vehicle. The LSC sends torque to the eLSD that sits between the rear wheels. The eLSD transfers torque to the two rear wheels. Follow the jump to continue reading more about the system.

Like with XWD, previous generation Haldex systems also included an LSC and an LSD. However, with the new system Haldex significantly redesigned the workings of their LSC. The LSC is still a clutch pack that adjusts torque split depending on hydraulic pressure. It is the method of fluid flow through the device that has changed. A large complaint about the old system was its lagging response time. LSC versions 3.0 and earlier used a built-in pump to create hydraulic pressure on the clutch pack to increase the torque drive to the rear wheels. While efforts were made on Haldex's part to create pre-emptive torque by adding a check valve and feeder pump to provide some instant pressure when triggered by wheel slippage, it was still limited in capacity. That is why for version 4.0 Haldex made an effort to improve response time by eliminating the hydraulic pump built in to the LSC, which also reduced its overall packaging size. Instead they have added a proportional pressure release valve with an accumulator that is kept filled by a detached feeder pump. This provides more instant response by holding the valve open to limit the torque drive to the rear wheels and keeping the hydraulic fluid flowing through the system. That way when rear torque is demanded, the valve closes and hydraulic pressure is already there.

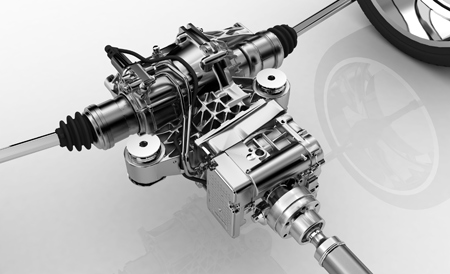

The above image shows the LSC unit on the left side. The component on the right side is the eLSD. Hydraulic lines can be seen running between them. Click the image for a high-res view.

The LSD used by Haldex 4.0 is also not the mechanical limited-slip differential of old. They swapped the old system LSD for an electronic unit. The eLSD works in much the same way as the LSC, a feeder pump and pressure relief valve are used to control hydraulic pressure on the differential clutch pack. This allows for complete control of the rear differential lock-up without the need to wait for wheel slippage to occur. The system has its own control unit contained in the LSC. This control unit communicates between the vehicle systems to get sensor input for data such as wheel speed, rpms, throttle position, steering wheel input, etc. It also works with anti-lock brake and traction control systems.

The above image shows a close up view of the LSC unit and eLSD. The eLSD sits between the rear axles and the LSC is mated to the driveshaft. The electronic control unit can be seen as a rectangle mounted on the nearside of the LSC. Click the image for a high-res view.

The XWD system can transmit 100 percent of available torque to either the front or rear wheels. However, for those conditions to occur one end of the vehicle would have to lose all traction, like driving on ice for instance. During a standing start the rear wheels are put to use, without the need for any slip to occur. Then under straight-line cruising conditions, to conserve fuel and driveline wear, the torque split to the rear wheels is reduced to a level between 5 and 10 percent. Also up to 40 percent of torque can be transferred by the eLSD between the two rear wheels to the one with more grip. The system can adjust torque splits based on calculated conditions, such as those that indicate an aggressive lane change maneuver, to effectively reduce overstreer or understeer without any wheel slip occurring. In the event that some wheel slip does actually get to occur, the system can react more timely and efficiently than in the past.

The above picture shows the XWD driveline. At the forefront of the picture is the eLSD coupled to the LSC unit. The PTU can be see at the opposing end of the driveshaft. Click the image for a high-res view.

The new Haldex system is an improvement on older iterations. Its characteristics are more like those of some of the Japanese manufactures such as Nissan or Mitsubishi than it is like the European Audi Quattro system. While the Haldex 4.0's integration into the Saab vehicles puts it into a front-wheel drive based platform it will be interesting to see if that won't be too much of a hindrance on performance. The Mitsubishi Lancer Evolution has been very successful despite its front-wheel drive base. It would be wonderful to see a Saab Turbo X get thrown in the X-Games Rally ring with all the Subraru WRX STIs or hit the tarmac in Time Attack against all the usual Evos. Until then, the most XWD action we get to see comes from a Saab hosted test drive event. Check out the embedded video below.

The video meant to be presented here is no longer available. Sorry for the inconvenience.

Sign in to post

Please sign in to leave a comment.

Continue