At the SAE World Congress, FEV is displaying a number of vehicles that they have contributed to recently including a diesel powered version of the new Chrysler Sebring and the Lincoln MKR concept. Perhaps the most interesting vehicle is a large brown UPS delivery van. This is no ordinary UPS truck though. This one has a series hybrid drivetrain, but even that is different. Unlike the Chevy Volt or the Ford Airstream/HySeries Edge, this van has no batteries for energy storage or electric motors. Instead this one has a hydraulic hybrid system.

Continue reading after the jump.

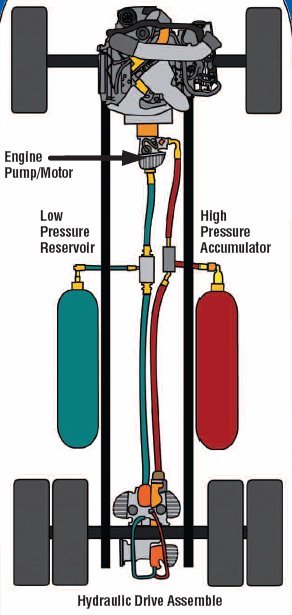

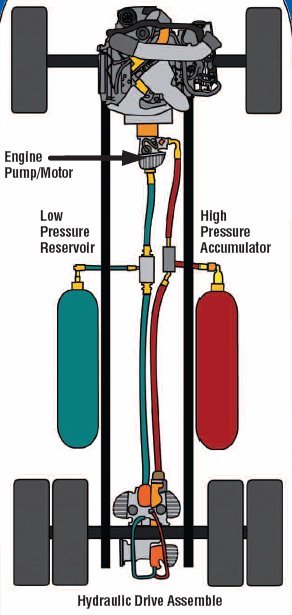

A conventional UPS van is powered by a diesel engine driving through a transmission and drive-shaft and rear axle. In the hydraulic hybrid version everything behind the engine is replaced. The diesel engine drives a hydraulic pump which draws fluid from a reservoir and pressurizes a high pressure accumulator. The accumulator acts as a power buffer, in a similar manner to a battery in an electric hybrid. The pressure from the accumulator is used to drive a hydraulic motor attached to the rear axle.

The hydraulic motor actually provides power to the rear axle to propel the vehicle. The fluid coming out the motor is fed back to the reservoir. Regenerative braking is achieved by having another hydraulic pump attached to the rear axle. When the driver lifts off the accelerator the rear axle drives the second pump which also pressurizes the accumulator. The resistance working back against the pump provides simulated engine braking. When the accumulator pressure is above a threshold the diesel engine can be shut off just as it would be with an electric hybrid.

The advantage a hydraulic hybrid system has over an battery electric system is the rate at which it can capture regenerative braking energy. Because a battery cannot absorb energy that quickly it can generally only capture about thirty percent of the energy from braking. A hydraulic system like this one can capture up to seventy percent of the braking energy. On the negative side, the hydraulic system has a limited energy capacity can only propel the vehicle short distances. The performance of the hydraulic hybrid system is actually more akin to a ultracapacitor, with the quick charge and discharge and limited capacity. Unlike the capacitors, the system is bulky and wouldn't be well suited to a smaller vehicle but is relatively simple and inexpensive for a system of it's size..

The system works very well on large 20,000 pound urban delivery trucks like this one. The continuous charging and discharging of the high pressure accumulator in this usage scenario takes maximum advantage of the system. FEV built two demonstration vehicles for UPS to test and they have been running since last fall. They have been testing several setups , including the engine running all the time, engine off when the vehicle is stopped and engine off when the vehicle is stopped or decelerating. Fuel consumption savings of 39-44 percent, 52-59 percent and 70-74 percent were found in the three scenarios. They also estimate a reduction in greenhouse gas emissions of forty percent.

Some of the hydraulic components used in the hybrid system

FEV estimates fuel savings of 1,000 gallons per year per vehicle and payback time for the hybrid system of only 2-3 years and $50,000 in lifetime savings per vehicle. FEV isn't a parts supplier, rather they are an engineering and design consultant. They do systems integration work and build prototypes for manufacturers. In this case FEV worked with UPS, EPA, Eaton, and International Truck to design and build these vehicles. Hopefully UPS and other delivery companies will take note of this and expand the use of such systems to all of their vehicles soon.

Continue reading after the jump.

A conventional UPS van is powered by a diesel engine driving through a transmission and drive-shaft and rear axle. In the hydraulic hybrid version everything behind the engine is replaced. The diesel engine drives a hydraulic pump which draws fluid from a reservoir and pressurizes a high pressure accumulator. The accumulator acts as a power buffer, in a similar manner to a battery in an electric hybrid. The pressure from the accumulator is used to drive a hydraulic motor attached to the rear axle.

The hydraulic motor actually provides power to the rear axle to propel the vehicle. The fluid coming out the motor is fed back to the reservoir. Regenerative braking is achieved by having another hydraulic pump attached to the rear axle. When the driver lifts off the accelerator the rear axle drives the second pump which also pressurizes the accumulator. The resistance working back against the pump provides simulated engine braking. When the accumulator pressure is above a threshold the diesel engine can be shut off just as it would be with an electric hybrid.

The advantage a hydraulic hybrid system has over an battery electric system is the rate at which it can capture regenerative braking energy. Because a battery cannot absorb energy that quickly it can generally only capture about thirty percent of the energy from braking. A hydraulic system like this one can capture up to seventy percent of the braking energy. On the negative side, the hydraulic system has a limited energy capacity can only propel the vehicle short distances. The performance of the hydraulic hybrid system is actually more akin to a ultracapacitor, with the quick charge and discharge and limited capacity. Unlike the capacitors, the system is bulky and wouldn't be well suited to a smaller vehicle but is relatively simple and inexpensive for a system of it's size..

The system works very well on large 20,000 pound urban delivery trucks like this one. The continuous charging and discharging of the high pressure accumulator in this usage scenario takes maximum advantage of the system. FEV built two demonstration vehicles for UPS to test and they have been running since last fall. They have been testing several setups , including the engine running all the time, engine off when the vehicle is stopped and engine off when the vehicle is stopped or decelerating. Fuel consumption savings of 39-44 percent, 52-59 percent and 70-74 percent were found in the three scenarios. They also estimate a reduction in greenhouse gas emissions of forty percent.

Some of the hydraulic components used in the hybrid system

FEV estimates fuel savings of 1,000 gallons per year per vehicle and payback time for the hybrid system of only 2-3 years and $50,000 in lifetime savings per vehicle. FEV isn't a parts supplier, rather they are an engineering and design consultant. They do systems integration work and build prototypes for manufacturers. In this case FEV worked with UPS, EPA, Eaton, and International Truck to design and build these vehicles. Hopefully UPS and other delivery companies will take note of this and expand the use of such systems to all of their vehicles soon.

Sign in to post

Please sign in to leave a comment.

Continue