In the last few months General Motors has been on real energy diversity kick. They seem to have bought wholeheartedly into the idea that monocultures are bad, particularly when it comes to energy supplies. While ninety-eight percent of the energy that we use for motorized transportation today is derived from petroleum, it isn't going to remain that way forever. We've already started seeing a shift toward biofuels and electric drive systems that can get their energy from any number of sources.

In the last few months General Motors has been on real energy diversity kick. They seem to have bought wholeheartedly into the idea that monocultures are bad, particularly when it comes to energy supplies. While ninety-eight percent of the energy that we use for motorized transportation today is derived from petroleum, it isn't going to remain that way forever. We've already started seeing a shift toward biofuels and electric drive systems that can get their energy from any number of sources.

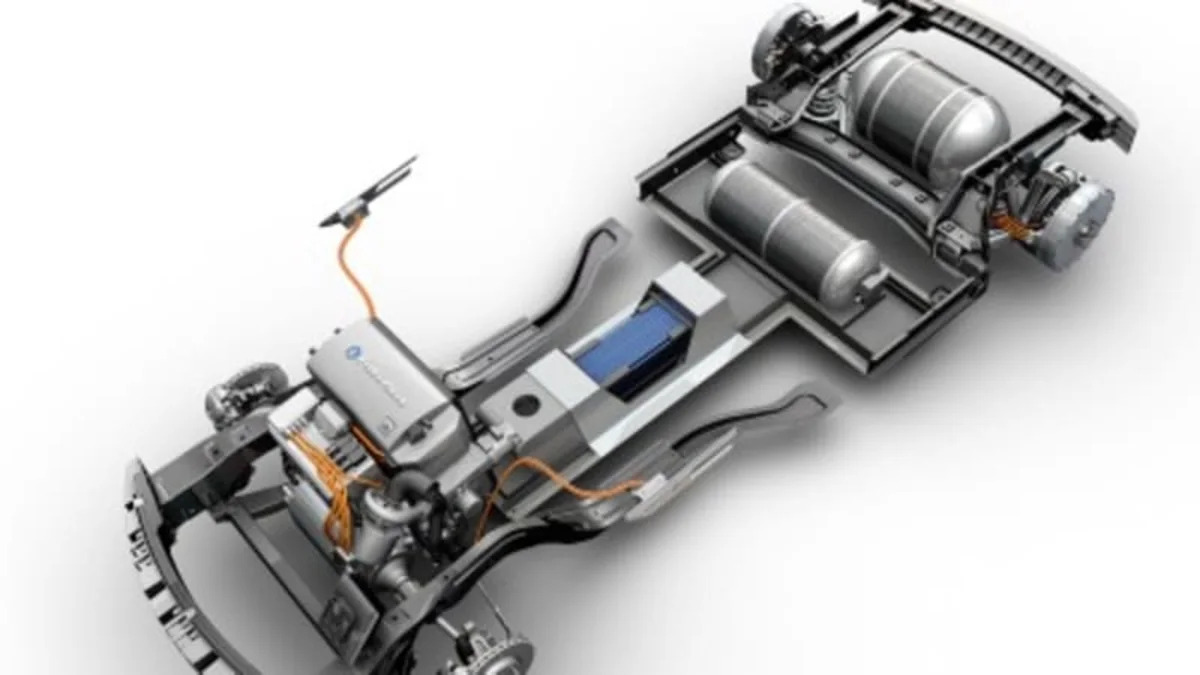

Back in January General Motors showed the world their new E-Flex electric drive platform in the form of a chassis mock-up of a plug-in series hybrid system and the Chevrolet Volt concept. At the time and repeatedly since GM has emphasized that the power-train system is designed to be modular and flexible to allow for many different energy sources to be used. They showed renderings of E-Flex powered entirely by batteries and also by fuel cells. At the 2007 Shanghai Motor Show, GM is unveiling the second major E-Flex variant with a hydrogen fuel cell powertrain. The new E-Flex version is powered by GM's new fifth-generation stack, which may well be the best performing fuel cell yet.

Continue reading all about the fuel cell E-Flex after the jump.

[Source: General Motors]

GM vice-president of Research and Development Larry Burns gave AutoblogGreen a preview of the new E-Flex and the fifth-generation stack that will be used on future GM fuel cell vehicles. The E-Flex system is built on top of the next generation of GM's global compact car platform which currently goes under the codename Delta and will be the basis of the replacements for the current Chevy Cobalt and Opel/Saturn Astra. This all means that major components like suspension, brakes, chassis rails and other items can be common between conventionally powered and E-Flex versions. All that should help keep the costs of E-Flex vehicles to a manageable level.

The original E-Flex used a plug-in series hybrid propulsion system with a 16kWh lithium ion battery and a flex-fuel internal combustion range extender. Version two still has plug-in capability but cuts the battery size in half (along with the battery-powered range). While the Volt and Ford's HySeries drive system both rely on the batteries as the primary source of electricity for the motor, the new edition uses the battery for supplementary power to reduce the transient loads on the fuel cell stack making it a parallel hybrid system. The 16kWh lithium ion battery pack of the original now has half as many cells and a capacity of 8kWh giving a battery range of 20 miles.

The original E-Flex used a plug-in series hybrid propulsion system with a 16kWh lithium ion battery and a flex-fuel internal combustion range extender. Version two still has plug-in capability but cuts the battery size in half (along with the battery-powered range). While the Volt and Ford's HySeries drive system both rely on the batteries as the primary source of electricity for the motor, the new edition uses the battery for supplementary power to reduce the transient loads on the fuel cell stack making it a parallel hybrid system. The 16kWh lithium ion battery pack of the original now has half as many cells and a capacity of 8kWh giving a battery range of 20 miles.

The same 70kW motor from the Volt drives the front wheels of the new chassis and is joined by a pair of 25kW hub motors at the back end to provide all wheel drive capability. The hub motors are GM's third generation coreless motors. They are more efficient and lighter than the units used in the Sequel. This is a similar arrangement to the existing Sequel concept, but aside from the basics of the powertrain configuration all the details are different.

While the Sequel used General Motors fourth-generation fuel stack in a horizontal arrangement in the skateboard chassis the E-Flex uses a fifth generation stack. The dramatically improved efficiency of the new design, allows the E-Flex to maintain the same 300-mile range but from only 4kg of hydrogen compared to the 8kg in the Sequel. The new stack is also only half the size of the old stack with the same power.

The new stack has a vertical orientation like the latest Honda vertical flow stack in the FCX concept but the hydrogen still flows horizontally through the stack. In spite of that, the new manufacturing techniques developed by General Motors have allowed them to increase the power density to 3kW/L and 2kW/kg. They can now get 80kW of power from a package that is half the size of the units in the Sequel and Equinox. By comparison the latest Honda stack only achieves 2kW/L and 1.5kW/kg.

At the same time the cost of the new generation stack has been reduced through the use of catalyst thrifting. GM has put a lot of effort in developing new ways of applying platinum to the electrodes in the stack to achieve an even spread while minimizing the amount needed. Larry Burns believes that GM will achieve their goal of having a fuel cell system design by the end of 2009 that can be produced in million-unit annual volumes at a cost of $50/kW with 150,000 mile life span and 300 mile range. That price point will put the system on a par with conventional internal combustion drivetrains. Because the volumes obviously won't be at the million unit level in that time frame, the costs will still be higher and drop as they ramp up production.

GM is actively working on the production engineering of both the series hybrid and fuel cell versions of the E-Flex platform although the series hybrid variant is likely to see higher volume production first. The lithium ion batteries are being tested now and given the developments that we've seen in the industry in the past two years, it seems likely that we will see something like this by 2010-11. After the Project Driveway Equinox production run is completed, the next fuel cell vehicle will probably be based on E-Flex. The chassis being shown at Shanghai is just a mock-up but GM is promising another big E-Flex announcement in September at the Frankfurt Motor Show. That one will likely be a fully functional running E-Flex vehicle prototype.

CHEVROLET VOLT CONCEPT SEDAN SPECIFICATIONS

Overview

| Model:

|

Chevrolet Volt Concept

|

| Body style / driveline:

|

4-5-passenger sedan, unitized frame, all wheel drive electric propulsion

|

| Construction:

|

body-frame-integral structure with composite exterior panels and roof

|

| EPA vehicle class

|

compact car (four doors with rear liftgate)

|

Propulsion System

| Description:

|

All wheel electrically driven propulsion system using a fuel cell and a "plug in" charged storage battery

|

| Fuel Cell:

|

|

| Type:

|

Proton Exchange Membrane

|

| Peak Power:

|

80 kW

|

| Continuous Power:

|

80 kW

|

| Hydrogen Storage Capacity:

|

4.0 kg in two Type 4 tanks

|

| Battery system:

|

|

| Type:

|

lithium-ion

|

| Energy:

|

8 kWh (total)

|

| Peak power:

|

50 kW

|

| Voltage:

|

320 to 350

|

| Charger:

|

|

| Type:

|

On board plug in

|

| Voltage / amp:

|

110 / 15 (typical household supply)

|

| Battery recharge time (80% SOC):

|

|

| 110-volt outlet:

|

3.5 to 4 hours

|

| Electric traction system:

|

|

| Front drive motor max mech power:

|

70 kW

|

| Front drive motor torque (lb-ft/Nm)

|

250 Nm (motor)

|

| Rear wheel motor max mech pwr (x2):

|

25 kW

|

| Rear drive motor torque (lb-ft/Nm) (x2)

|

500 Nm (wheel)

|

| Electric mode range:

|

20 miles – on battery stored power

|

| 0 to 60 mph:

|

8 to 8.5 seconds

|

| Top speed – Burst (mph)

|

120 mph

|

| Top speed – Continuous (mph)

|

100 mph

|

Chassis/Suspension

| Front:

|

independent, strut-type

|

| Rear:

|

semi-independent torsion beam

|

| Steering type:

|

electric, speed-sensitive, variable assist rack-and-pinion

|

| Turning circle, curb-to-curb (ft / m):

|

37 to 38 / 11.2 to 11.5

|

Brakes

| Type:

|

electro-hydraulic power assisted; front disc, rear drum

|

Wheels/Tires

| Wheel size (in):

|

21 x 6.5

|

| Tires:

|

195/55R21, low-rolling resistance

|

Dimensions

Exterior

| Overall length (in / mm):

|

170 / 4318

|

| Height (in / mm):

|

52.6 / 1336

|

| Width (in / mm):

|

70.5 / 1791

|

Interior

| Seating capacity (front / rear):

|

2 / 2

|

| Headroom (in / mm):

|

front: 37.3 / 947

rear: 35.9 / 912

|

| Legroom (in / mm):

|

31.5 / 802

|

| Shoulder room (in / mm):

|

50.6 / 1285

|

| Hip room (in / mm):

|

53.1 / 1349

|

Related:

Sign in to post

Please sign in to leave a comment.

Continue