In June of 2005 Honda became the first car company in the world to lease a hydrogen fuel cell powered car to Jon Spallino, of Redondo Beach, California. During the 2005-6 auto show season, they showed off a concept version of their first purpose-built fuel cell powered car. Earlier this year they announced that the car would go into low volume production in 2008 and yesterday they allowed a group of journalists to drive the first two prototypes at the Laguna Seca racetrack along with the two of the current generation FCX cars. I was there.

The day began with a technical presentation of where Honda's fuel cell development has been and where it's going. Unlike most other car-makers working on hydrogen power, Honda is designing and building their own fuel cell stacks. The previous generations of stacks have been laid out much like the ones from companies like Ballard where the gases flow horizontally through the stack. This horizontal flow is what has led to one of the problems with fuel cells in cars, cold weather performance.

(Continued after the jump)

In a horizontal stack, the hydrogen and oxygen produce electricity and water, some which condenses and sticks to the plates in the stack and eventually drips down and is drained out. The plates have horizontal channels which can make the drainage problematic, sometimes leaving liquid water in the stack which, if allowed to freeze, can damage it. The horizontal layout was chosen because of the size of stacks and the need to keep the center of gravity of the car low.

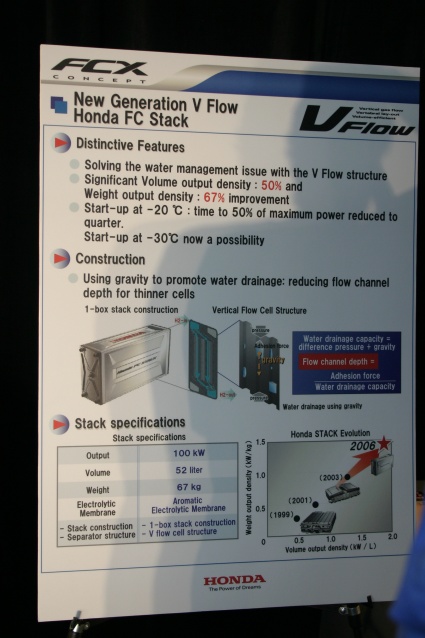

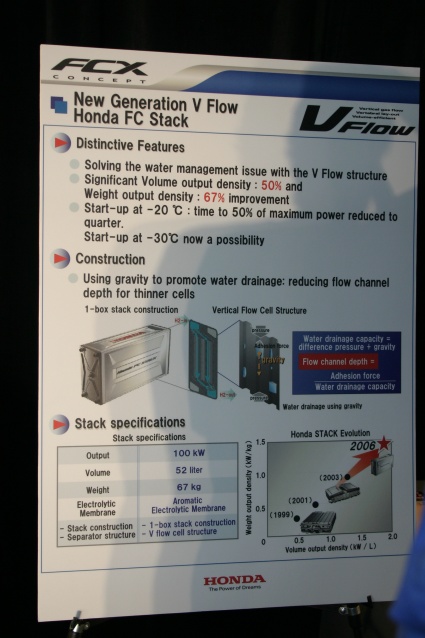

The major innovation of the new FCX concept is the new V-Flow fuel cell stack, where V stands for vertical. In this stack, the hydrogen and oxygen enter from the top and flow down through the stack. The channels in the plates are now vertical, and allow the water to flow out much more freely. Water on the plates reduces the electrical generating capacity and makes it inconsistent. In the new stack, the lack of standing water on the plates allows for much higher and more consistent power generation, and the better drainage means much lower operating temperature capability.

Honda R&D Americas VP Ben Knight discussing the evolution of the Honda fuel cell stacks.

Executive Chief Engineer Yozo Kami discussing the new V-Flow stack.

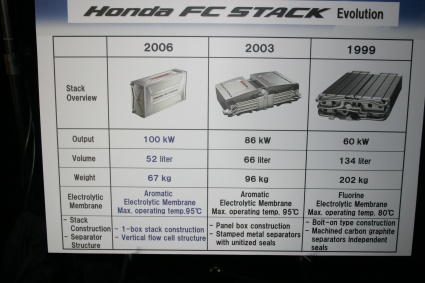

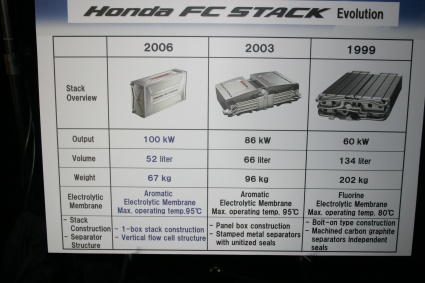

The end result is a power generation unit that has a power/volume density ratio 50 percent higher than the previous generation introduced in 2003 and a 67 percent improvement in power/weight ratio. Compared to the unit from 1999 those numbers are up by a factor of four. So they now have a stack that is small enough and powerful enough to fit upright in the center tunnel of the car.

This desich allows the floorpan and seats to now be moved much lower, allowing for vastly improved design flexibility. The current generation FCX is based on the design of the EV+ electric car built in the nineties, making it a tall four seat hatchback with the ultra capacitor (instead of a battery) sitting under the floor. The new FCX has the fuel cell mounted in the center tunnel between the driver and front passenger seat, and is a remarkably sleek-looking four door, four passenger sport sedan. The two cars are like night and day.

(Click for Part 2, Part 3 and Part 4)

The Spallino family, first retail fuel cell customers with Yozo Kami and Sachito Fujimoto, Executive Chief Engineers and the old and new FCX models.

The day began with a technical presentation of where Honda's fuel cell development has been and where it's going. Unlike most other car-makers working on hydrogen power, Honda is designing and building their own fuel cell stacks. The previous generations of stacks have been laid out much like the ones from companies like Ballard where the gases flow horizontally through the stack. This horizontal flow is what has led to one of the problems with fuel cells in cars, cold weather performance.

(Continued after the jump)

In a horizontal stack, the hydrogen and oxygen produce electricity and water, some which condenses and sticks to the plates in the stack and eventually drips down and is drained out. The plates have horizontal channels which can make the drainage problematic, sometimes leaving liquid water in the stack which, if allowed to freeze, can damage it. The horizontal layout was chosen because of the size of stacks and the need to keep the center of gravity of the car low.

The major innovation of the new FCX concept is the new V-Flow fuel cell stack, where V stands for vertical. In this stack, the hydrogen and oxygen enter from the top and flow down through the stack. The channels in the plates are now vertical, and allow the water to flow out much more freely. Water on the plates reduces the electrical generating capacity and makes it inconsistent. In the new stack, the lack of standing water on the plates allows for much higher and more consistent power generation, and the better drainage means much lower operating temperature capability.

Honda R&D Americas VP Ben Knight discussing the evolution of the Honda fuel cell stacks.

Executive Chief Engineer Yozo Kami discussing the new V-Flow stack.

The end result is a power generation unit that has a power/volume density ratio 50 percent higher than the previous generation introduced in 2003 and a 67 percent improvement in power/weight ratio. Compared to the unit from 1999 those numbers are up by a factor of four. So they now have a stack that is small enough and powerful enough to fit upright in the center tunnel of the car.

This desich allows the floorpan and seats to now be moved much lower, allowing for vastly improved design flexibility. The current generation FCX is based on the design of the EV+ electric car built in the nineties, making it a tall four seat hatchback with the ultra capacitor (instead of a battery) sitting under the floor. The new FCX has the fuel cell mounted in the center tunnel between the driver and front passenger seat, and is a remarkably sleek-looking four door, four passenger sport sedan. The two cars are like night and day.

(Click for Part 2, Part 3 and Part 4)

The Spallino family, first retail fuel cell customers with Yozo Kami and Sachito Fujimoto, Executive Chief Engineers and the old and new FCX models.

Sign in to post

Please sign in to leave a comment.

Continue