It's one thing for the Big 3 to get tires and engine parts from cities along the US Rust Belt. It's another thing altogether, though, for Tesla Motors to source far more esoteric materials like graphite, cobalt and lithium from Canada and the northern US. But that's what the California-based company has in mind, and it's all in the name of environmental friendliness and cost, Bloomberg News says.

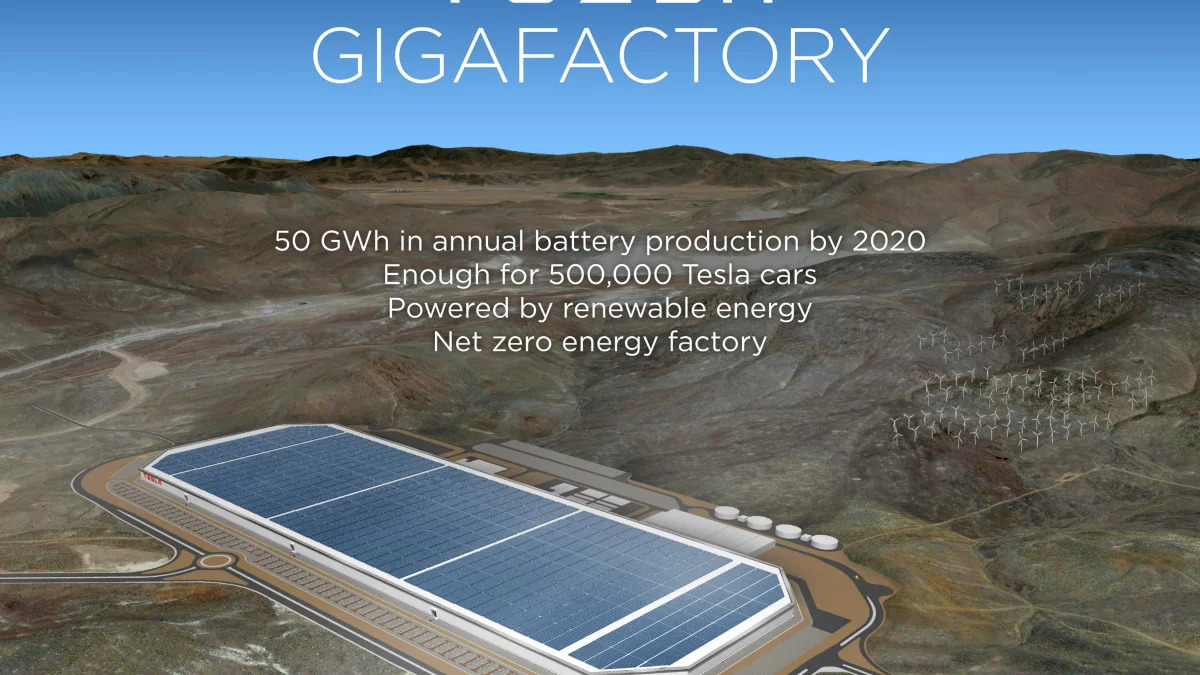

Tesla is looking to bring its raw-material sourcing to this side of the Pond by the time it opens its massive gigafactory that may produce as many as 500,000 vehicles annually, Bloomberg says, citing Tesla spokeswoman Liz Jarvis-Shean. And while the raw-material price may be higher (and driven up further with the additional demand from Tesla), those costs may be offset by the fact that there will be far less transportation and logistics involved.

There are geopolitical issues as well. For instance, China is shutting down some of its graphite mines because of pollution issues, while much of the world's cobalt comes from war-torn Congo, though Tesla says it gets its cobalt from the Philippines. Most of the graphite in Tesla's Model S is of the synthetic variety from Japan and Europe.

Of course, Tesla's still trying to figure out where to put its gigafactory, and has said it will be in one of four states: Arizona, Nevada, New Mexico or Texas. The factory will cost an estimated $5 billion and may support 6,500 jobs, so state governments are already starting to campaign to be the automaker's future production home. Regardless, Jarvis-Shean estimated that the sheer economies of scale from the gigafactory will reduce battery-pack costs per kilowatt hour for the company's "mass market" model (sometimes referred to as the Model E) by 30 percent after a full year of production.

Tesla is looking to bring its raw-material sourcing to this side of the Pond by the time it opens its massive gigafactory that may produce as many as 500,000 vehicles annually, Bloomberg says, citing Tesla spokeswoman Liz Jarvis-Shean. And while the raw-material price may be higher (and driven up further with the additional demand from Tesla), those costs may be offset by the fact that there will be far less transportation and logistics involved.

"Transportation impacts are very significant on the heaviest raw materials if they need to be moved from halfway around the world," Jarvis-Shean wrote in an e-mail to AutoblogGreen, adding that there will be additional cost savings from reduced shipping time and less transit-related working capital requirements. "In the long term, when all costs are considered, it should be cheaper to source most materials from as nearby as possible.""When all costs are considered, it should be cheaper to source most materials from as nearby as possible" - Tesla's Liz Jarvis-Shean

There are geopolitical issues as well. For instance, China is shutting down some of its graphite mines because of pollution issues, while much of the world's cobalt comes from war-torn Congo, though Tesla says it gets its cobalt from the Philippines. Most of the graphite in Tesla's Model S is of the synthetic variety from Japan and Europe.

Of course, Tesla's still trying to figure out where to put its gigafactory, and has said it will be in one of four states: Arizona, Nevada, New Mexico or Texas. The factory will cost an estimated $5 billion and may support 6,500 jobs, so state governments are already starting to campaign to be the automaker's future production home. Regardless, Jarvis-Shean estimated that the sheer economies of scale from the gigafactory will reduce battery-pack costs per kilowatt hour for the company's "mass market" model (sometimes referred to as the Model E) by 30 percent after a full year of production.

Sign in to post

Please sign in to leave a comment.

Continue