Why Not Improve The Cheap Chemistry?

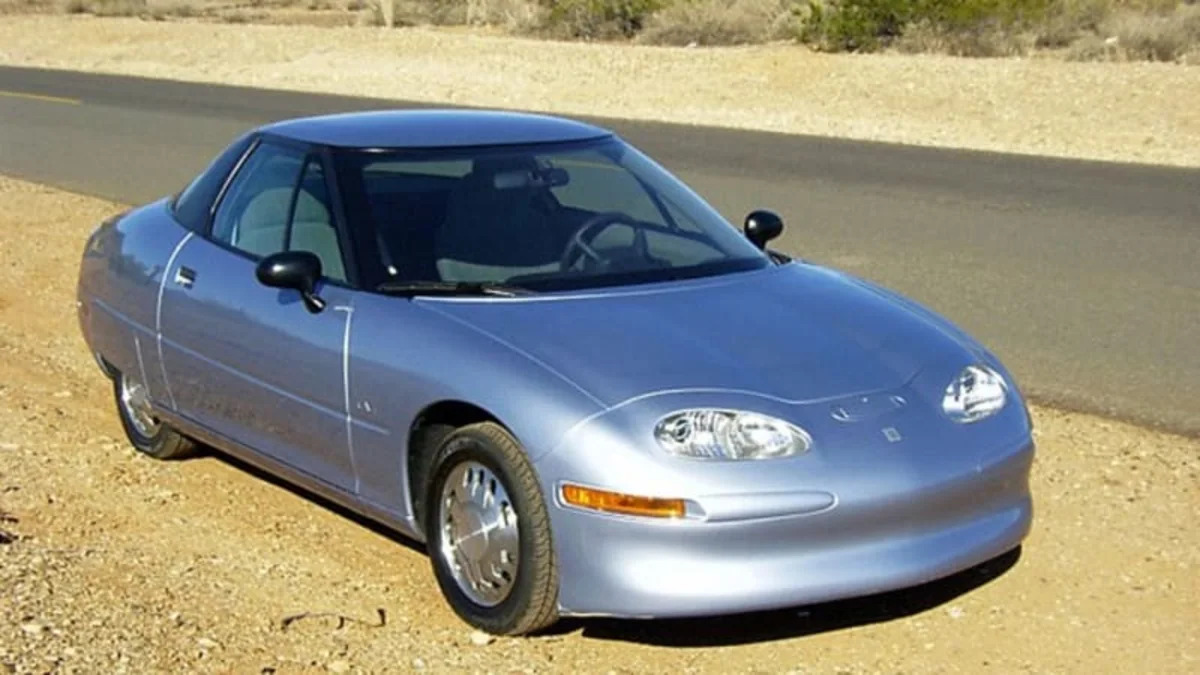

When General Motors launched its pioneering two-seat EV1 in 1997, its batteries were "advanced" lead acid (PbA). That means they were big, heavy, had low energy density and a limited life. But it was the best available chemistry at the time. That first EV1's T-shaped pack of 27 PbA modules weighed nearly 1200 pounds and stored the energy equivalent of a half-gallon of gas. The fact that you could coax 50-70 miles of (warm-weather, flat-road) range out of that tiny amount of on-board energy was a testament to the extreme efficiency of that car.

Then, by working hard with Nickel Metal Hydride (NiMH) developer Ovonic Battery Co., GM was able to offer an optional NiMH pack for the '99 EV1. Roughly the same size and weight as the PbA pack, it required the addition of a cooling system and was much more expensive, but it approximately doubled on-board energy. So, 1999 model year NiMH EV1 drivers could leave home with the equivalent of an entire gallon of gas in their "tank" and drive 100-plus miles.

But lithium-polymer, the next generation battery technology that was supposed to make BEVs much more affordable and practical, never came close to matching expectations. And it wasn't long before PbA's low energy and NiMH's much higher cost put an end to California's ridiculous EV sales mandate – and all the major automakers' production pure EV programs – for a while.

Today's renewed hope for volume EV sales is thanks largely to the emergence of lithium-ion battery chemistry, which roughly doubles the energy density of NiMH and quadruples PbA. But li-ion costs even more than NiMH, so the growing list of EVs and hybrids that use it are still way more expensive than conventional ICE counterparts.

"We have been working on developing very advanced battery systems based on lead-acid chemistry," he says. "When I concluded my assignment with Envia two years ago, I realized that we in the battery industry had been making a lot of promises, going back to 1991, to achieve the performance and cost targets that would enable the transportation industry to switch over to electrified powertrains. The focus has been how far you can go on a charge, so the bulk of the effort has been to maximize energy density while keeping an eye on cost.

Dhar concluded that as long as EV batteries required expensive materials – nickel, cobalt, copper and rare-earth metals in NiMH, expensive electrolyte used in li-ion – the hope that their cost would come down with volume and time was unrealistic. So why not try something different? Instead of chasing the highest-performance chemistry, then trying to figure out a way to reduce the cost, what if they would start with the lowest-cost chemistry and try improving its performance?

So he set out to optimize PbA chemistry and battery design in hopes of achieving the power (not necessarily energy) density of NiMH. "If we can do that without disturbing the fundamental cost structure of the chemistry, that is potentially a winner, maybe the solution.

He put together a team of people with experience in NiMH and li-ion batteries and materials science to work on microstructure technology and battery composition, to start thinking "out of the box" and taking a completely different approach to developing a product using PbA chemistry by working on the cathode and anode materials, the substrate, the grid and how the batteries would be designed and assembled. He thought 45-50 Wh/kg might be possible, but not the 150 currently demonstrated by li-ion.

And NiMH is still expensive. "In the late '90s, early 2000s, the Prius battery was $2,500-2,800 per vehicle," he says, "and my guess is that it's still $1,700-$1,800, even though it's a small battery. My belief is that if NiMH batteries were magically cut in cost by a factor of three, we would see a significant surge in the growth of hybrid electric vehicles. With micro hybrids, mild hybrids, even full hybrids, you don't need a battery that's more than 1.2-1.5 kWh, provided you can achieve enough power to add torque to your powertrain at an acceptable cost."

Dhar thinks advanced PbA might also have potential in plug-ins and big-battery EVs. "We are developing solutions for micro, mild and full hybrids, but we also have approaches for applying this product to PHEVs, EREVs and pure EVs. I believe we can combine our high-power, low-cost battery with a lower-cost, higher-energy li-ion battery to make a hybrid pack that could reduce the overall cost by a factor of two. I think it's possible to make a high-energy li-ion battery for maybe $400 per kWh or less, and if I take, say, 10 kWh of high-energy Li-ion battery and attach it to 2-1/2 or three kWh of EPS high-power battery, I can shift the power load to the EPS battery and use energy from the li-ion battery for cruising. The combined cost of this system should be 40-50 percent less than a li-ion pack optimized for both high power and high energy."

Dhar has kept this effort low-profile because he did not want to be another over-optimistic battery developer going public with bold statements and promises he ultimately can't keep. He has seen that happen way too often. "I understand why people sometimes have to do that," he says, "to raise capital. In our case, we are fortunate that raising capital is not our issue today, or likely to be tomorrow." That is because, he says, EPS has more than sufficient backing from his partner Dennis Townsend, founder and chairman of Baltimore-based Townsend Capital.

Dhar has kept this effort low-profile because he did not want to be another over-optimistic battery developer going public with bold statements and promises he ultimately can't keep. He has seen that happen way too often. "I understand why people sometimes have to do that," he says, "to raise capital. In our case, we are fortunate that raising capital is not our issue today, or likely to be tomorrow." That is because, he says, EPS has more than sufficient backing from his partner Dennis Townsend, founder and chairman of Baltimore-based Townsend Capital.

When we talked, he had put off approaching automakers because he wanted to be further down the development road before he did. "I don't want a large gap between talking to them and when I can say, "Here is a prototype, go test it." But you may see Subhash Dhar and EPS telling their advanced PbA story at the Advanced Automotive Batteries Conference (AABC) next February and at a trade show or two in 2013.

Editor's Note: A timely coincidence showed up in our inbox as we were getting this post ready. A new report from Pike Research on "Advanced Lead-Acid Batteries." We're not going to spend the nearly $4,000 it costs to read, but this shows Dhar isn't the only one taking another look at lead-acid batteries.

When General Motors launched its pioneering two-seat EV1 in 1997, its batteries were "advanced" lead acid (PbA). That means they were big, heavy, had low energy density and a limited life. But it was the best available chemistry at the time. That first EV1's T-shaped pack of 27 PbA modules weighed nearly 1200 pounds and stored the energy equivalent of a half-gallon of gas. The fact that you could coax 50-70 miles of (warm-weather, flat-road) range out of that tiny amount of on-board energy was a testament to the extreme efficiency of that car.

Then, by working hard with Nickel Metal Hydride (NiMH) developer Ovonic Battery Co., GM was able to offer an optional NiMH pack for the '99 EV1. Roughly the same size and weight as the PbA pack, it required the addition of a cooling system and was much more expensive, but it approximately doubled on-board energy. So, 1999 model year NiMH EV1 drivers could leave home with the equivalent of an entire gallon of gas in their "tank" and drive 100-plus miles.

But lithium-polymer, the next generation battery technology that was supposed to make BEVs much more affordable and practical, never came close to matching expectations. And it wasn't long before PbA's low energy and NiMH's much higher cost put an end to California's ridiculous EV sales mandate – and all the major automakers' production pure EV programs – for a while.

Today's renewed hope for volume EV sales is thanks largely to the emergence of lithium-ion battery chemistry, which roughly doubles the energy density of NiMH and quadruples PbA. But li-ion costs even more than NiMH, so the growing list of EVs and hybrids that use it are still way more expensive than conventional ICE counterparts.

But Troy, MI start-up Energy Power Systems (EPS) founder/CEO Subhash Dhar – who has toiled in the EV battery business for more than 30 years – contends that PbA deserves another chance. Along with inventor Stan Ovshinsky, he founded Ovonic in 1981. Then he was involved in li-ion development as vice chairman of EnerDel and president of Ener1. He then served as chairman and CEO of Envia Systems, a developer of advanced battery anode and cathode materials (and which GM has an interest in). And now he's searching for hidden potential in good old PbA.The search is on for hidden potential in good old PbA (lead-acid) batteries.

"We have been working on developing very advanced battery systems based on lead-acid chemistry," he says. "When I concluded my assignment with Envia two years ago, I realized that we in the battery industry had been making a lot of promises, going back to 1991, to achieve the performance and cost targets that would enable the transportation industry to switch over to electrified powertrains. The focus has been how far you can go on a charge, so the bulk of the effort has been to maximize energy density while keeping an eye on cost.

"We made that promise in the early '90s and repeated it in the early 2000's, and the industry has made significant advances in energy density, battery life and performance. But the issue still remains the cost. We are still at $600-$700 per kilowatt hour, depending on the chemistry, the system and the vehicle, against a target set back in 1991-92 of $150. So for a pure electric vehicle with a 30-kWh battery pack, we're talking $20-plus thousand just in the battery, which is not an economically viable proposition from the consumer standpoint.""We in the battery industry had been making a lot of promises, going back to 1991."

Dhar concluded that as long as EV batteries required expensive materials – nickel, cobalt, copper and rare-earth metals in NiMH, expensive electrolyte used in li-ion – the hope that their cost would come down with volume and time was unrealistic. So why not try something different? Instead of chasing the highest-performance chemistry, then trying to figure out a way to reduce the cost, what if they would start with the lowest-cost chemistry and try improving its performance?

So he set out to optimize PbA chemistry and battery design in hopes of achieving the power (not necessarily energy) density of NiMH. "If we can do that without disturbing the fundamental cost structure of the chemistry, that is potentially a winner, maybe the solution.

He put together a team of people with experience in NiMH and li-ion batteries and materials science to work on microstructure technology and battery composition, to start thinking "out of the box" and taking a completely different approach to developing a product using PbA chemistry by working on the cathode and anode materials, the substrate, the grid and how the batteries would be designed and assembled. He thought 45-50 Wh/kg might be possible, but not the 150 currently demonstrated by li-ion.

And NiMH is still expensive. "In the late '90s, early 2000s, the Prius battery was $2,500-2,800 per vehicle," he says, "and my guess is that it's still $1,700-$1,800, even though it's a small battery. My belief is that if NiMH batteries were magically cut in cost by a factor of three, we would see a significant surge in the growth of hybrid electric vehicles. With micro hybrids, mild hybrids, even full hybrids, you don't need a battery that's more than 1.2-1.5 kWh, provided you can achieve enough power to add torque to your powertrain at an acceptable cost."

So his focus has been on improving power density. "We have taken the power of lead-acid chemistry from the typical 200-300 watts per kilogram to 2000, and we have seen cycle-life improvements in our prototypes by factors of three to four. We have accomplished that by taking out all the dead weight, increasing the utilization of active materials and redesigning the pack for reduced internal resistance, so its reactions are faster. The rate at which you put electrons in and draw electrons out of this pack are five to six times faster than today's best power-density PbA battery." His vision is to offer a power-to-energy ratio of 30 to 35 at lead-acid chemistry cost. "Some companies have done that with li-ion, but at four times that cost.""I believe we can combine our high-power, low-cost battery with a lower-cost, higher-energy li-ion battery to make a hybrid pack that could reduce the overall cost by a factor of two."

Dhar thinks advanced PbA might also have potential in plug-ins and big-battery EVs. "We are developing solutions for micro, mild and full hybrids, but we also have approaches for applying this product to PHEVs, EREVs and pure EVs. I believe we can combine our high-power, low-cost battery with a lower-cost, higher-energy li-ion battery to make a hybrid pack that could reduce the overall cost by a factor of two. I think it's possible to make a high-energy li-ion battery for maybe $400 per kWh or less, and if I take, say, 10 kWh of high-energy Li-ion battery and attach it to 2-1/2 or three kWh of EPS high-power battery, I can shift the power load to the EPS battery and use energy from the li-ion battery for cruising. The combined cost of this system should be 40-50 percent less than a li-ion pack optimized for both high power and high energy."

Dhar has kept this effort low-profile because he did not want to be another over-optimistic battery developer going public with bold statements and promises he ultimately can't keep. He has seen that happen way too often. "I understand why people sometimes have to do that," he says, "to raise capital. In our case, we are fortunate that raising capital is not our issue today, or likely to be tomorrow." That is because, he says, EPS has more than sufficient backing from his partner Dennis Townsend, founder and chairman of Baltimore-based Townsend Capital.

Dhar has kept this effort low-profile because he did not want to be another over-optimistic battery developer going public with bold statements and promises he ultimately can't keep. He has seen that happen way too often. "I understand why people sometimes have to do that," he says, "to raise capital. In our case, we are fortunate that raising capital is not our issue today, or likely to be tomorrow." That is because, he says, EPS has more than sufficient backing from his partner Dennis Townsend, founder and chairman of Baltimore-based Townsend Capital.

When we talked, he had put off approaching automakers because he wanted to be further down the development road before he did. "I don't want a large gap between talking to them and when I can say, "Here is a prototype, go test it." But you may see Subhash Dhar and EPS telling their advanced PbA story at the Advanced Automotive Batteries Conference (AABC) next February and at a trade show or two in 2013.

Editor's Note: A timely coincidence showed up in our inbox as we were getting this post ready. A new report from Pike Research on "Advanced Lead-Acid Batteries." We're not going to spend the nearly $4,000 it costs to read, but this shows Dhar isn't the only one taking another look at lead-acid batteries.

Sign in to post

Please sign in to leave a comment.

Continue