Reducing internal engine friction is Federal-Mogul's goal and, with its CarboGlide piston ring coating, the company seems to have mastered the art of making metal slippery. According to Federal-Mogul, CarboGlide delivers a direct improvement in fuel economy and CO2 emissions by reducing ring friction by up to 20 percent, compared to other commonly used coatings.

CarboGlide is Federal-Mogul's third DLC (diamond-like carbon) coated-ring technology. The coating was developed in Burscheid, Germany and several vehicle manufacturers will launch engines using CarboGlide-coated piston rings later this year. Federal-Mogul says CarboGlide's wear resistance will withstand an engine's full operational life and protects the cylinder walls from scuffing and scoring.

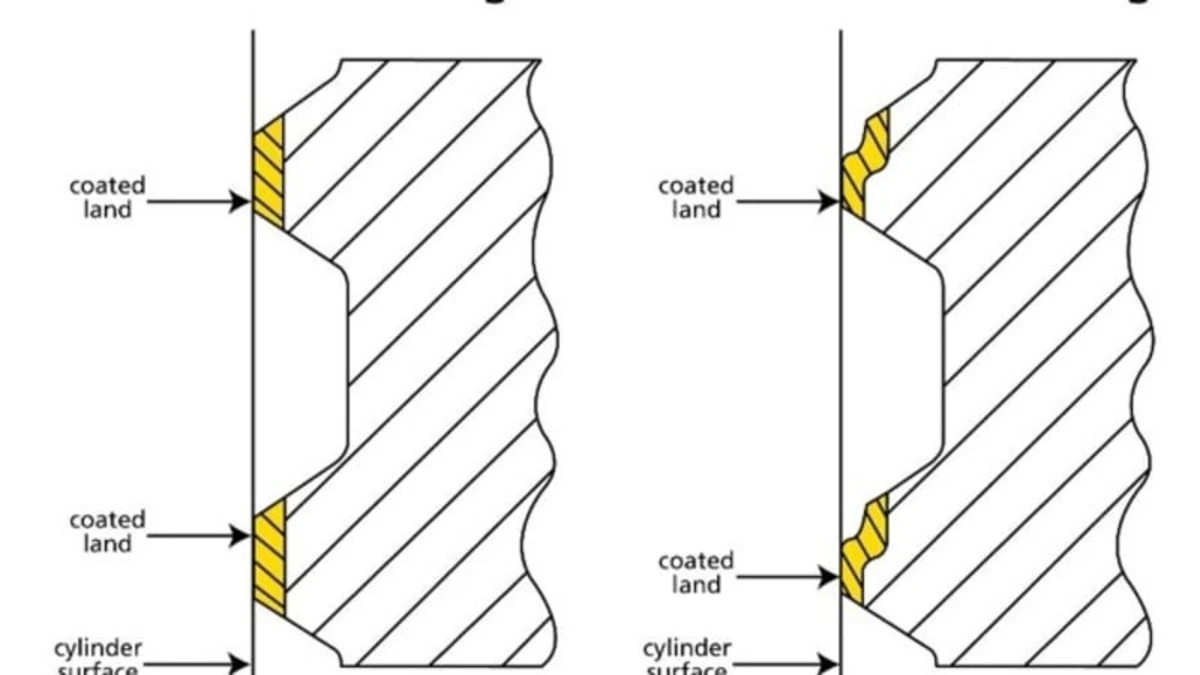

CarboGlide consists of a multi-layer, carbon-containing microstructure deposited in diamond-like form. This unique coating, according to Federal-Mogul, can be up to 10 microns thick, more than three times that of the rest of the industry's DLC coatings.

In terms of boosting fuel economy, Federal-Mogul makes no claim that CarboGlide will reduce fuel consumption by a set amount. Rather, the company says that reduced friction improves engine performance and fuel economy, while reducing CO2 emissions.

CarboGlide is Federal-Mogul's third DLC (diamond-like carbon) coated-ring technology. The coating was developed in Burscheid, Germany and several vehicle manufacturers will launch engines using CarboGlide-coated piston rings later this year. Federal-Mogul says CarboGlide's wear resistance will withstand an engine's full operational life and protects the cylinder walls from scuffing and scoring.

CarboGlide consists of a multi-layer, carbon-containing microstructure deposited in diamond-like form. This unique coating, according to Federal-Mogul, can be up to 10 microns thick, more than three times that of the rest of the industry's DLC coatings.

In terms of boosting fuel economy, Federal-Mogul makes no claim that CarboGlide will reduce fuel consumption by a set amount. Rather, the company says that reduced friction improves engine performance and fuel economy, while reducing CO2 emissions.

IMPROVES FUEL ECONOMY AND REDUCES CO2 EMISSIONS

Innovative CarboGlide® piston ring coating provides low friction and superior scuffing

protection for full operational life of latest-generation gasoline engines

SOUTHFIELD, Mich., August 8, 2011 ... Federal-Mogul Corporation (NASDAQ: FDML) has

developed a new piston ring coating that supports vehicle manufacturers' efforts to make

gasoline engines more fuel-efficient. The company's patented CarboGlide® coating delivers a

direct improvement in fuel economy and CO2 emissions by reducing ring friction by up to 20

percent as compared to nitride or other commonly used coatings. CarboGlide's high wear

resistance will withstand an engine's full operational life-even in the latest generation of high output gasoline engines with turbocharging or direct injection. CarboGlide additionally protects

the cylinder surface from scuffing and scoring, especially under the most critical lubrication

conditions, because of its high chemical and physical stability.

"CarboGlide provides engine manufacturers and vehicle owners with a strong advantage over

other coated rings in the market by delivering an extremely low friction coefficient, superior wear resistance and long life," said Rainer Jueckstock, senior vice president, Federal-Mogul

Powertrain Energy. "Our CarboGlide-coated rings provide engine manufacturers with an

immediate, cost-effective fuel economy improvement that is easy to implement. The frictionreducing, fuel-economy improvement benefits contribute also to reduce the carbon footprint of gasoline-powered vehicles," Jueckstock added.

CarboGlide's superior coating properties are achieved due to a multi-layer microstructure and a

special coating composition that contains carbon, deposited in diamond-like form, as well as

hydrogen and tungsten. The unique structure can be produced for a coating thickness of 10

microns, more than three times that of the industry's latest state-of-the-art DLC coating. A

specialized advanced process based on the combination of Physical Vapour Deposition and

Plasma-Assisted Chemical Vapor Deposition, specifically developed for piston ring application,

is used in applying CarboGlide. The coating's multi-layer architecture, together with the

company's surface machining and finishing expertise, ensure the integrity of the coating

structure, optimal adhesion of the coating and high coating stability on both steel and cast iron

rings.

"Federal-Mogul tests on engines, using both cast iron and high-silicon aluminum cylinder

surfaces, have shown that CarboGlide-coated rings minimize friction and scuffing for the full

expected life of the engine, even in the challenging environment typical of GDI turbo engines,"

said Dr. Marcus Kennedy, Federal-Mogul's manager, Physical Coatings. "It is highly stable due

to its non-metallic nature. The unique combination of low friction, low wear and scuffing

resistance also makes the technology attractive for application to other Federal-Mogul products

developed for extreme conditions like face seals on construction machinery," Kennedy added.

CarboGlide is Federal-Mogul's third and most advanced generation of the company's DLC

coated ring technology. The coating was developed in Burscheid, Germany, at one of the

company's 18 globally-networked technical centers.

Several leading vehicle manufacturers will launch engines using Federal-Mogul's CarboGlidecoated piston rings beginning this year.

Federal-Mogul will exhibit its CarboGlide-coated rings, along with other leading technologies

from the company that improve fuel economy, reduce vehicle emissions and enhance vehicle

safety, at the 64th International Auto Show in Frankfurt, Germany.

About Federal-Mogul

Federal-Mogul Corporation is a leading global supplier of powertrain and safety solutions to the

world's foremost original equipment manufacturers of automotive, commercial, aerospace,

marine, rail and off-road vehicles; industrial, agricultural and power generation equipment; as

well as the worldwide aftermarket. Federal-Mogul's leading technology and innovation, lean

manufacturing expertise, and global distribution network deliver world-class products, brands

and services at a competitive cost. The company's sustainable global profitable growth strategy

creates value for its employees, customers and shareholders. Federal-Mogul was founded in

Detroit in 1899. The company is headquartered in Southfield, Michigan, and employs

approximately 45,000 people in 35 countries.

Innovative CarboGlide® piston ring coating provides low friction and superior scuffing

protection for full operational life of latest-generation gasoline engines

SOUTHFIELD, Mich., August 8, 2011 ... Federal-Mogul Corporation (NASDAQ: FDML) has

developed a new piston ring coating that supports vehicle manufacturers' efforts to make

gasoline engines more fuel-efficient. The company's patented CarboGlide® coating delivers a

direct improvement in fuel economy and CO2 emissions by reducing ring friction by up to 20

percent as compared to nitride or other commonly used coatings. CarboGlide's high wear

resistance will withstand an engine's full operational life-even in the latest generation of high output gasoline engines with turbocharging or direct injection. CarboGlide additionally protects

the cylinder surface from scuffing and scoring, especially under the most critical lubrication

conditions, because of its high chemical and physical stability.

"CarboGlide provides engine manufacturers and vehicle owners with a strong advantage over

other coated rings in the market by delivering an extremely low friction coefficient, superior wear resistance and long life," said Rainer Jueckstock, senior vice president, Federal-Mogul

Powertrain Energy. "Our CarboGlide-coated rings provide engine manufacturers with an

immediate, cost-effective fuel economy improvement that is easy to implement. The frictionreducing, fuel-economy improvement benefits contribute also to reduce the carbon footprint of gasoline-powered vehicles," Jueckstock added.

CarboGlide's superior coating properties are achieved due to a multi-layer microstructure and a

special coating composition that contains carbon, deposited in diamond-like form, as well as

hydrogen and tungsten. The unique structure can be produced for a coating thickness of 10

microns, more than three times that of the industry's latest state-of-the-art DLC coating. A

specialized advanced process based on the combination of Physical Vapour Deposition and

Plasma-Assisted Chemical Vapor Deposition, specifically developed for piston ring application,

is used in applying CarboGlide. The coating's multi-layer architecture, together with the

company's surface machining and finishing expertise, ensure the integrity of the coating

structure, optimal adhesion of the coating and high coating stability on both steel and cast iron

rings.

"Federal-Mogul tests on engines, using both cast iron and high-silicon aluminum cylinder

surfaces, have shown that CarboGlide-coated rings minimize friction and scuffing for the full

expected life of the engine, even in the challenging environment typical of GDI turbo engines,"

said Dr. Marcus Kennedy, Federal-Mogul's manager, Physical Coatings. "It is highly stable due

to its non-metallic nature. The unique combination of low friction, low wear and scuffing

resistance also makes the technology attractive for application to other Federal-Mogul products

developed for extreme conditions like face seals on construction machinery," Kennedy added.

CarboGlide is Federal-Mogul's third and most advanced generation of the company's DLC

coated ring technology. The coating was developed in Burscheid, Germany, at one of the

company's 18 globally-networked technical centers.

Several leading vehicle manufacturers will launch engines using Federal-Mogul's CarboGlidecoated piston rings beginning this year.

Federal-Mogul will exhibit its CarboGlide-coated rings, along with other leading technologies

from the company that improve fuel economy, reduce vehicle emissions and enhance vehicle

safety, at the 64th International Auto Show in Frankfurt, Germany.

About Federal-Mogul

Federal-Mogul Corporation is a leading global supplier of powertrain and safety solutions to the

world's foremost original equipment manufacturers of automotive, commercial, aerospace,

marine, rail and off-road vehicles; industrial, agricultural and power generation equipment; as

well as the worldwide aftermarket. Federal-Mogul's leading technology and innovation, lean

manufacturing expertise, and global distribution network deliver world-class products, brands

and services at a competitive cost. The company's sustainable global profitable growth strategy

creates value for its employees, customers and shareholders. Federal-Mogul was founded in

Detroit in 1899. The company is headquartered in Southfield, Michigan, and employs

approximately 45,000 people in 35 countries.

Sign in to post

Please sign in to leave a comment.

Continue