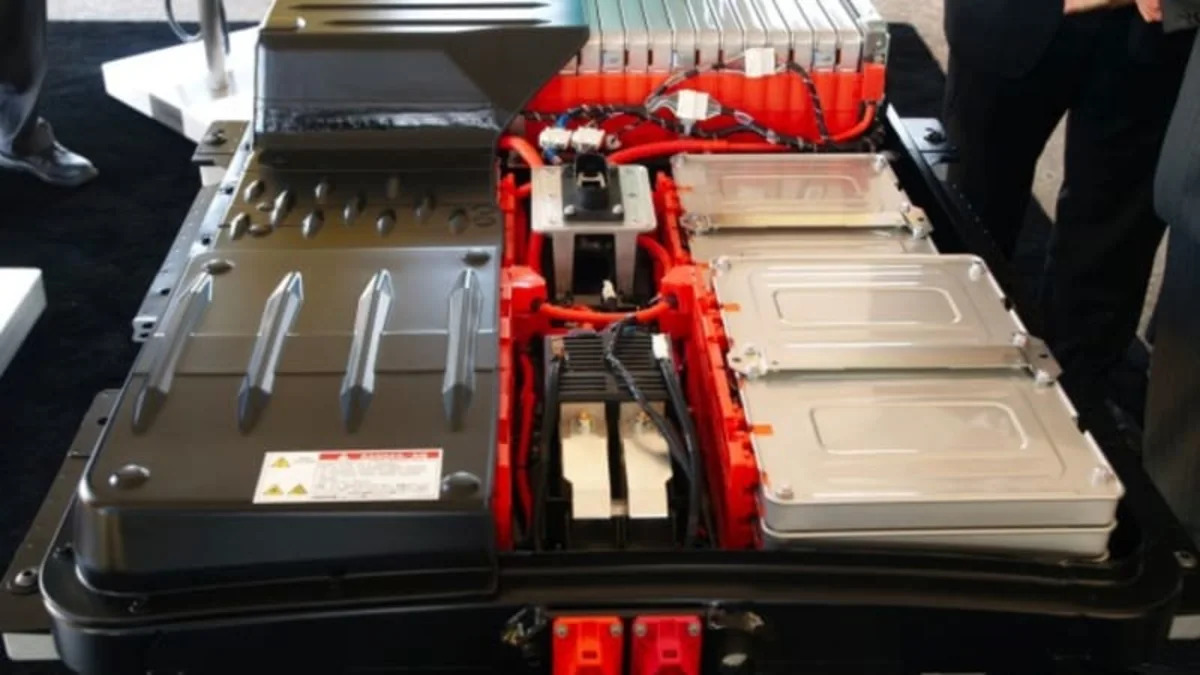

Nissan Leaf battery pack – Click above for high-res image gallery

As automakers decide upon the best approach for marketing and selling their upcoming battery-powered vehicles, manufacturing engineers are scrambling to find the best ways to make them. As Norm Bafunno, president of Toyota Motor Manufacturing, Indiana Inc. said, "Electric vehicles present an engineering challenge even for the most flexible automakers." Bafunno said that electric vehicles (EVs) commonly utilize many materials and parts which are not present in conventional autos and this presents a problem at the assembly line because many manufacturing facilities are not equipped to accommodate material changes or the installation of additional parts such as the Leaf's underbody battery cover.

Of course, Nissan is already ironing out the details as it begins to ready its plant in Smyrna, TN for Leaf production. Susan Brennan, vice president of manufacturing at the Nissan plant, recently spoke about the manufacturing challenges with Automotive News (sub. req.) and building the Leaf may require some manual overhead work – a potentially dangerous task that has been eliminated by the company. She said, "There will be some challenges for us to figure out. But if we can't, the consequences for us are too great." Surely there will be hurdles to overcome as automakers venture into EV production, but we're entirely confident that the industry will come up with creative solutions to build these cars.

Sign in to post

Please sign in to leave a comment.

Continue