It's only a matter of time before cars' suspensions become a part of the electric power-regeneration process (similar to regenerative braking), and that time is coming very soon courtesy of ZF Friedrichshafen AG and Levant Power Corp. Levant Power has been developing what it calls GenShock-technology, the first active suspension system with the ability to recapture energy, and ZF has entered a partnership with the Massachusetts-based company to build it.

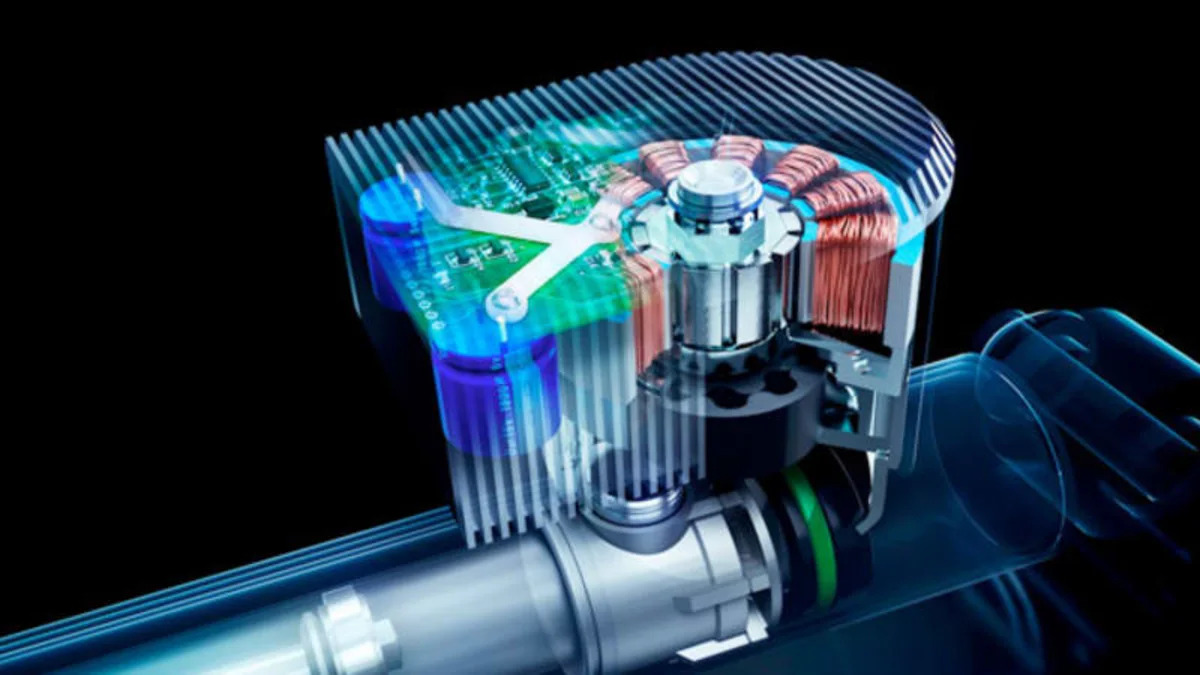

The active dampers employ a new type of valve technology to regulate the flow of oil in the shocks, which is the basis for the active and regenerative characteristics. The technology is contained in a device mounted to the outside of each shock. The device houses its own control unit, an electric motor and an electrohydraulic gear pump, and controls the flow of fluid in the shocks to adjust the damping rate, like a normal active damper.

The process is reversed when the shock is regenerating energy. As the vehicle is traversing uneven terrain or is unsettled in a turn, during acceleration or while braking, the swaying motion of the piston in the damper pushes fluid past the electrohydraulic gear pump, which drives the electric motor and converts the kinetic energy into electricity that is fed back into the power supply. If you think that a system like this would function better on poor road surfaces, you're right. The rougher the road surface, the more movement the damper experiences, which generates more electricity.

Portable jacks also could be a thing of the past for cars that use ZF's and Levant Power's new suspension system, because it's capable of actively raising each individual wheel - perfect for a roadside spare-tire change.

Click on the image above to enlarge, and read about the details of the new suspension system in the press release below. And read carefully, as regenerative suspension has the potential to be the next big suspension breakthrough.

The active dampers employ a new type of valve technology to regulate the flow of oil in the shocks, which is the basis for the active and regenerative characteristics. The technology is contained in a device mounted to the outside of each shock. The device houses its own control unit, an electric motor and an electrohydraulic gear pump, and controls the flow of fluid in the shocks to adjust the damping rate, like a normal active damper.

The process is reversed when the shock is regenerating energy. As the vehicle is traversing uneven terrain or is unsettled in a turn, during acceleration or while braking, the swaying motion of the piston in the damper pushes fluid past the electrohydraulic gear pump, which drives the electric motor and converts the kinetic energy into electricity that is fed back into the power supply. If you think that a system like this would function better on poor road surfaces, you're right. The rougher the road surface, the more movement the damper experiences, which generates more electricity.

Portable jacks also could be a thing of the past for cars that use ZF's and Levant Power's new suspension system, because it's capable of actively raising each individual wheel - perfect for a roadside spare-tire change.

Click on the image above to enlarge, and read about the details of the new suspension system in the press release below. And read carefully, as regenerative suspension has the potential to be the next big suspension breakthrough.

ZF and Levant Power Develop the World's First Fully Active, Regenerative Suspension for Automobiles

- ZF Friedrichshafen AG has entered into partnership with Levant Power Corp. to build the world's first fully active suspension system with energy recovery function

- GenShock-technology is a fully active system for passenger cars which combines dynamics, safety and comfort characteristics with minimum energy consumption

- Intelligent, simple design creates the basis for future cost-effective volume production

Automakers have long sought a suspension that allows sport cars handling while maintaining the comfort of a premium luxury sedan. The difficulty in achieving this outcome rests in balancing comfort and handling; comfort requires a soft suspension to absorb bumps, while handling requires stiffness for control. Previous attempts to achieve high-bandwidth active suspension have fallen short due to cost, complexity and power consumption. ZF and Levant Power are now developing GenShock-technology to unite the vast gains of active suspension with modest power consumption, minimal complexity and affordable cost.

The recently agreed cooperation between ZF Friedrichshafen AG and Levant Power Corp., based in Woburn, Mass., U.S., paves the way for revolutionary damper technology. "We look forward to working closely together with Levant Power. The objective is to develop the world's first fully active and regenerative suspension, make it ready for volume production and introduce it to the market. Thus, we are promoting efficient innovations that are tailored to meet global requirements," said Rolf Heinz Rüger, in charge of the Suspension Technology business unit of ZF's Car Chassis Technology division.

"Ride and handling are at the core of the driving experience. With GenShock-technology, ZF and Levant will reinvent that experience," continued Shakeel Avadhany, Founder & CEO of Levant Power.

Newly conceived valve

An innovative functional unit, fitted to the outside of the ZF damper, forms the technological basis of the active, regenerative system. The valve technology has been developed specifically for this application. The very compact unit is composed of its own control unit, an electric motor and an electrohydraulic gear pump. Driven by an electronically controlled electric motor, the gear pump regulates the oil flow in the damper. "For dynamics, comfort and safety, it is essential that active forces can be applied into the chassis," explained Rüger. For this reason, the damping characteristic curve not only adapts optimally and automatically to each driving situation, but bodywork pitch motions are also virtually eliminated during abrupt braking maneuvers and rolling motions. Moreover, the technology is capable of actively raising each individual wheel.

Electricity for the vehicle power supply

As soon as the driving situation permits, the innovative valve system automatically uses the swaying motion of the damper piston to recover energy. Then, the system guides the oil in the damper in such a way that it drives the electric pump motor. This then functions like a generator; it converts the generated kinetic energy into electricity and feeds it into the vehicle power supply, thus contributing to a reduction in CO2 emissions. This effect is most powerful when the vehicle is traveling on poor quality country roads.

With this project, ZF is making use of its long-standing know-how of adaptive dampers. Continuous Damping Control (CDC) has been winning over vehicle manufacturers since its market launch in 1994 and is still doing so with its fourth generation. The production numbers continue to rise; 2011 marked the temporary record high with more than 2.2 million dampers produced for the following customers: Alpina, Audi, Bentley, BMW, Ferrari, Maserati, Opel, Rolls-Royce, Mercedes-Benz, Porsche and Volkswagen. A total of around 14 million CDC systems have already come off the production line at ZF, and the company expects an annual production of more than three million CDC units for passenger car applications alone by 2016. In addition, there are ZF systems for buses, trucks, agricultural machines and motorcycles.

About:

ZF is a global leader in driveline and chassis technology with 121 production companies in 26 countries. In 2012, the Group achieved a sales figure of about EUR 17.4 billion with approximately 75,000 employees. In order to continue to be successful with innovative products, ZF annually invests about five percent of its sales (2012: EUR 861 million) in research and development. ZF is one of the 10 largest automotive suppliers worldwide.

Levant Power Corp. is an emerging technology company headquartered in Woburn, Massachusetts working to develop the world's first fully active, regenerative suspension for the automotive, trucking, mass transit, and defense industries. The company holds several patents focused primarily on vehicle dynamics, and is the originator of GenShock and Activalve technology. Levant Power was founded in 2009 out of the Massachusetts Institute of Technology.

- ZF Friedrichshafen AG has entered into partnership with Levant Power Corp. to build the world's first fully active suspension system with energy recovery function

- GenShock-technology is a fully active system for passenger cars which combines dynamics, safety and comfort characteristics with minimum energy consumption

- Intelligent, simple design creates the basis for future cost-effective volume production

Automakers have long sought a suspension that allows sport cars handling while maintaining the comfort of a premium luxury sedan. The difficulty in achieving this outcome rests in balancing comfort and handling; comfort requires a soft suspension to absorb bumps, while handling requires stiffness for control. Previous attempts to achieve high-bandwidth active suspension have fallen short due to cost, complexity and power consumption. ZF and Levant Power are now developing GenShock-technology to unite the vast gains of active suspension with modest power consumption, minimal complexity and affordable cost.

The recently agreed cooperation between ZF Friedrichshafen AG and Levant Power Corp., based in Woburn, Mass., U.S., paves the way for revolutionary damper technology. "We look forward to working closely together with Levant Power. The objective is to develop the world's first fully active and regenerative suspension, make it ready for volume production and introduce it to the market. Thus, we are promoting efficient innovations that are tailored to meet global requirements," said Rolf Heinz Rüger, in charge of the Suspension Technology business unit of ZF's Car Chassis Technology division.

"Ride and handling are at the core of the driving experience. With GenShock-technology, ZF and Levant will reinvent that experience," continued Shakeel Avadhany, Founder & CEO of Levant Power.

Newly conceived valve

An innovative functional unit, fitted to the outside of the ZF damper, forms the technological basis of the active, regenerative system. The valve technology has been developed specifically for this application. The very compact unit is composed of its own control unit, an electric motor and an electrohydraulic gear pump. Driven by an electronically controlled electric motor, the gear pump regulates the oil flow in the damper. "For dynamics, comfort and safety, it is essential that active forces can be applied into the chassis," explained Rüger. For this reason, the damping characteristic curve not only adapts optimally and automatically to each driving situation, but bodywork pitch motions are also virtually eliminated during abrupt braking maneuvers and rolling motions. Moreover, the technology is capable of actively raising each individual wheel.

Electricity for the vehicle power supply

As soon as the driving situation permits, the innovative valve system automatically uses the swaying motion of the damper piston to recover energy. Then, the system guides the oil in the damper in such a way that it drives the electric pump motor. This then functions like a generator; it converts the generated kinetic energy into electricity and feeds it into the vehicle power supply, thus contributing to a reduction in CO2 emissions. This effect is most powerful when the vehicle is traveling on poor quality country roads.

With this project, ZF is making use of its long-standing know-how of adaptive dampers. Continuous Damping Control (CDC) has been winning over vehicle manufacturers since its market launch in 1994 and is still doing so with its fourth generation. The production numbers continue to rise; 2011 marked the temporary record high with more than 2.2 million dampers produced for the following customers: Alpina, Audi, Bentley, BMW, Ferrari, Maserati, Opel, Rolls-Royce, Mercedes-Benz, Porsche and Volkswagen. A total of around 14 million CDC systems have already come off the production line at ZF, and the company expects an annual production of more than three million CDC units for passenger car applications alone by 2016. In addition, there are ZF systems for buses, trucks, agricultural machines and motorcycles.

About:

ZF is a global leader in driveline and chassis technology with 121 production companies in 26 countries. In 2012, the Group achieved a sales figure of about EUR 17.4 billion with approximately 75,000 employees. In order to continue to be successful with innovative products, ZF annually invests about five percent of its sales (2012: EUR 861 million) in research and development. ZF is one of the 10 largest automotive suppliers worldwide.

Levant Power Corp. is an emerging technology company headquartered in Woburn, Massachusetts working to develop the world's first fully active, regenerative suspension for the automotive, trucking, mass transit, and defense industries. The company holds several patents focused primarily on vehicle dynamics, and is the originator of GenShock and Activalve technology. Levant Power was founded in 2009 out of the Massachusetts Institute of Technology.

Sign in to post

Please sign in to leave a comment.

Continue