Mechanism used to "force unintended acceleration - Click above for high-res image gallery

In a video webcast for the media that concluded a just a few moments ago, Toyota hit back at the "simulated unintended acceleration" demonstration that was shown by ABC News late last month. When we saw the original report, we postulated that the condition Gilbert produced may not be representative of a scenario that can actually happen in the real world, and judging by Toyota's findings, we were right.

As reported on Friday, Toyota went to an independent testing firm called Exponent to attempt to replicate the results from the Gilbert study. Dr. Shukri J. Souri of Exponent acknowledged that Gilbert did indeed create a scenario that produced what looked like a valid accelerator pedal signal to the electronic engine management system. But before demonstrating how the test was performed, Souri explained how the pedal sensor wiring works and showed how the connector is constructed. As we expected, Gilbert's testing methods and ABC News' report are very much in question. Make the jump for our full breakdown.

[Source: Toyota]

Tired of Toyota recall news? Try out the recall-free version of Autoblog.

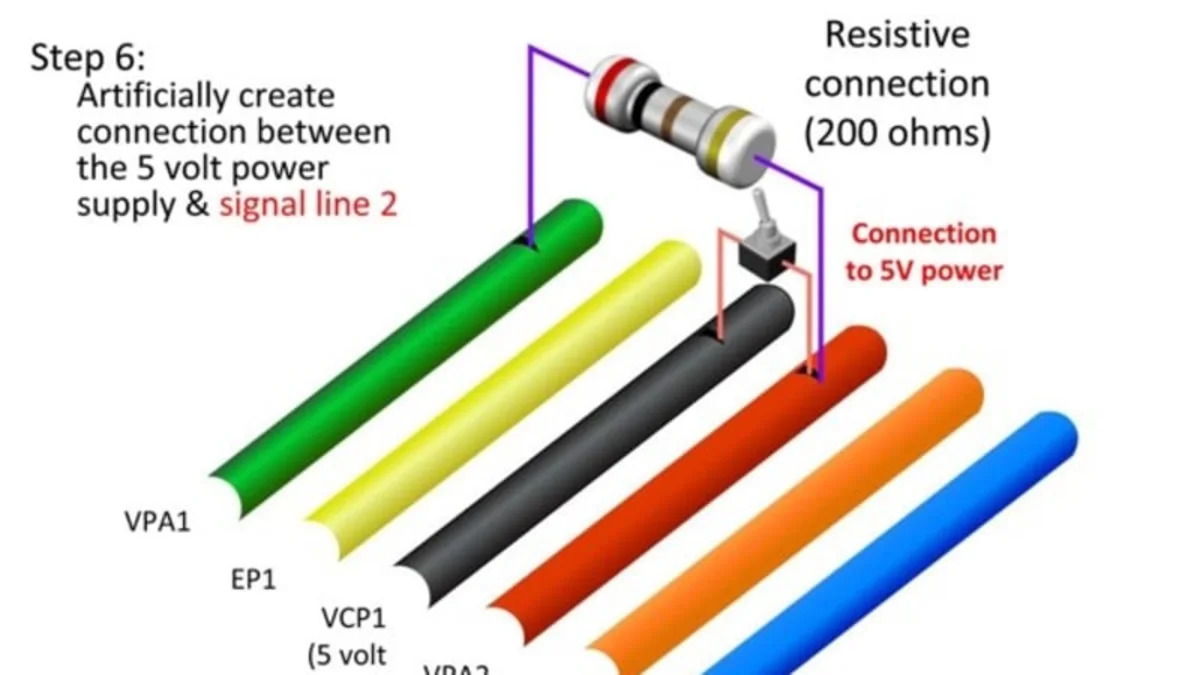

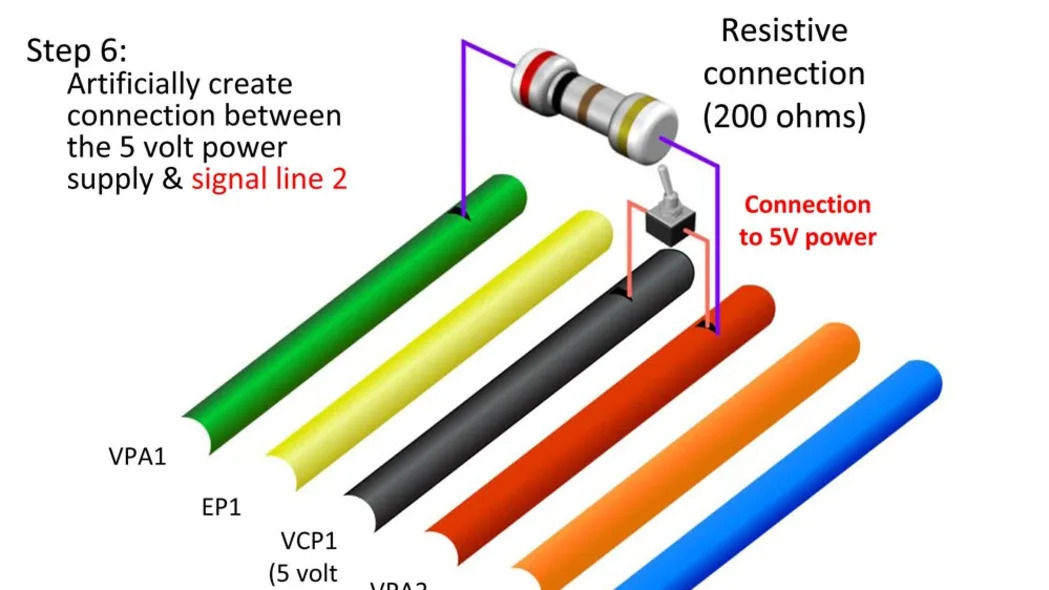

The Toyota's normal pedal sensor configuration consists of two independent sensors that produce voltages in different ranges, and there should always be a correlation between the voltages. One of the ways a fault in the sensor system can be detected is if the signals does not rise or fall in the correct relationship.

The wires in the connector are in-line, and Souri's team actually sectioned a connector to show all the insulation between the six wires. Gilbert's setup required breaching three of the six wires, attaching a 200 ohm resistor between two of them and then shorting the third line with full power to the resistance circuit.

This methodology provides a voltage input to the two circuits. The presence of the 200 ohm resistor ensures that the relationship between the two signals remains within the parameters the ECU is expecting. If there is more or less resistance, the relationship between the two signals will not be maintained and a fault should be detected.

This methodology provides a voltage input to the two circuits. The presence of the 200 ohm resistor ensures that the relationship between the two signals remains within the parameters the ECU is expecting. If there is more or less resistance, the relationship between the two signals will not be maintained and a fault should be detected.

Given the nature of the connector between the wiring harness and the pedal assembly, it's highly unlikely that such a scenario could ever occur in the real world. The only way this is could occur is if the insulation on the wires in the harness itself was stripped away (exactly the way Gilbert did for his test) and just the right amount of resistance occurred only between the two signal lines. Obviously, such a scenario is unlikely.

According to Kristen Tabar of Toyota, the resistance range that will work is very narrow. The 200 ohm resistance is not something that could occur with any materials that are likely to appear in the vehicle environment. For example, water intrusion would produce resistance in the 1,000+ ohm region. A straight short of the wires would be well below 200 ohms. Either scenario would trigger a fault code.

During the webcast, Toyota and Exponent demonstrated the same scenario on a Ford Fusion, BMW 325i and Subaru Legacy (they also had a host of other vehicles on hand) and each vehicle replicated the racing engine condition without signaling a fault code, although each one required a different resistance value. Like pretty much every modern vehicle available, these vehicles use a similar type of gas pedal architecture.

So what does this all prove? First, it demonstrates that with a bit of re-engineering of the pedal circuit, any engine can be made to race independently of what the driver commands with their foot. David Gilbert was able to modify the Toyota pedal sensor circuit to make this happen within the parameters that the fault diagnosis system was expecting so that no fault was detected.

What it doesn't prove is that Gilbert's scenario is a possible cause of the issues that drivers have seen. In fact, based on how this test was conducted, it's almost impossible that this is the cause of Toyota's unintended acceleration woes.

In no way does any of this exonerate Toyota with regard to a potential software problem. It's too early tell if a errant black box is the cause and we still have no evidence one way or the other on this count. This also doesn't discount the possibility of some other electrical (such as electromagnetic interference) or mechanical problem that we aren't aware of at this time. So the mystery continues... Toyota's press release is available below.

COMPREHENSIVE ANALYSIS RAISES CONCERNS ABOUT GILBERT CONGRESSIONAL TESTIMONY, ABC NEWS SEGMENT

Sequence and Nature of Artificially Manipulated Faults Unrealistic, Televised "Unintended Acceleration" Staged With Virtual Remote Throttle Control

TORRANCE, Calif., March 8, 2010 /PRNewswire/ - Today, during a live webcast, Toyota raised serious concerns about the validity, methodology and credibility of a demonstration of alleged "unintended acceleration" in a Toyota Avalon by Professor David Gilbert of Southern Illinois University and depicted in ABC News broadcasts and on-line segments.

A comprehensive analysis conducted by a world renowned engineering group, as well as testing by Toyota, has concluded the following about Professor Gilbert's demonstration:

The vehicle's electronics were rewired and reengineered in multiple ways, in a specific sequence, and under conditions that are virtually impossible to occur in real-world conditions without visible evidence.

Toyota vehicle electronic systems were actively manipulated to mimic a valid full-throttle condition.

Substantially similar results were successfully created in vehicles made by other manufacturers.

In the demonstration dramatized by ABC on February 22, Professor Gilbert, assisted by segment reporter Brian Ross, asserted that he had detected a "dangerous" flaw in the Toyota electronic control system that he alleged could lead to unintended acceleration. The following day, Professor Gilbert offered a preliminary report of his findings in testimony to the U.S. House of Representatives Energy and Commerce Subcommittee on Oversight and Investigations.

Engineers at Exponent, one of the country's leading engineering and scientific consulting firms, as well as Toyota engineers, have reviewed and recreated Gilbert's demonstration with substantially similar results in representative vehicles of other makes.

Separately, at Toyota's request, Dr. J. Christian Gerdes, associate professor of mechanical engineering at Stanford University and the director of the Center for Automotive Research at Stanford (CARS), conducted an independent review of Professor Gilbert's testimony and the preliminary report presented to Congress.

Their findings were demonstrated today at a news conference during which the accelerator circuitry of a Toyota Avalon, as well as a sampling of well-regarded and popular competitive makes, was rewired and manipulated as Gilbert did in his demonstration.

Kristen Tabar, general manager of electronics systems, Toyota Technical Center, summarizes three of the major concerns with the artificial nature of Professor Gilbert's demonstration.

"First, an electrical circuit that has been reengineered and rewired will not behave as it was originally designed and engineered," said Tabar.

"Second, no automaker can or should be expected to design detection strategies for artificially created events in the absence of any evidence that such an event can occur in the real world.

"Third, if the artificial condition created by Professor Gilbert had occurred in the real world, it would have left readily detectable fingerprints."

Exponent and Toyota engineers have found no evidence to suggest that any of the steps of Professor Gilbert's demonstration exists in the real world. Thus, the fact that the Toyota Avalon used by Professor Gilbert did not show a Diagnostic Trouble Code after his demonstration does not indicate an undetectable safety defect. The same is true of the representative vehicles of other manufacturers tested by Exponent and Toyota.

Professor Gilbert's reengineering and rewiring of the vehicle's electrical system involves the following manipulations in a specific sequence. First, the protective insulation on two separate wires that carry the accelerator pedal position signals to the Engine Control Module must be individually cut or breached. Next, these wires are connected to each other through a 200 Ohm resistor.

This contrivance, by itself, did not cause an increase in engine speed. To cause an increase in engine speed, it is necessary to cut the insulation on a third wire, the 5-volt power supply to the accelerator pedal, and force a low resistance connection between the power supply and the secondary signal wire.

The resulting increase in engine speed is a result of the subsequent artificial and sudden application of the 5-volt power supply to this signal line with the rewired circuit. When subjected to similar unrealistic reengineering and rewiring, the competitive vehicles evaluated by Exponent and Toyota achieved substantially similar results with varying levels of resistances.

This manipulation of electrical components and a power source created artificial voltages that the engine control module, or ECM, would interpret as valid accelerator pedal signals. In essence, this test created a virtual, remote control accelerator pedal that replicated the vehicle's own normally functioning accelerator pedal.

Also contrary to statements made in the ABC News story, had short circuits of the kind artificially created by Professor Gilbert occurred in real-world driving conditions, they would have left visible evidence such as damage or deterioration of the wiring and components.

As revealed in their testimony before Congress, Professor Gilbert's Preliminary Report was commissioned by Sean Kane, a paid advocate for trial lawyers involved in litigation against Toyota and other automakers. Mr. Kane also appeared on the ABC News broadcast in support of the claim that Professor Gilbert's demonstration revealed a flaw in the electronic throttle control system that could lead to "runaway" Toyota and Lexus vehicles. The relationship between Mr. Kane, Professor Gilbert and the trial lawyers who support Mr. Kane's advocacy was not revealed by ABC News during the newscast, nor was Toyota offered an opportunity to view the demonstration or given time to respond.

Toyota believes that the public and Congressional committees have been misled by Professor Gilbert's demonstration and the dramatization of it by ABC News. This has cast unwarranted doubt on the safety of Toyota and Lexus vehicles. Toyota remains confident in the integrity of the electronic throttle control system in its vehicles and there has been no reliable evidence of any kind to the contrary presented to the media or to Congress. Toyota's electronic systems have multiple fail-safe mechanisms to shut off or reduce engine power in the event of a system failure. Extensive testing of this system by Toyota has not found any sign of a malfunction that could lead to unintended acceleration.

Toyota has commissioned Exponent to conduct a comprehensive analysis of the electronic throttle control systems in Toyota and Lexus vehicles. No limitations of any kind were imposed on Exponent by Toyota. This evaluation is ongoing. An interim report of Exponent's findings has been provided to Congress and establishes the functionality of the electronic throttle control fail-safe systems. The final results of Exponent's exhaustive analysis will be made public when completed. As with all such reliable engineering analyses, Exponent's final results will provide the data and information necessary for others to validate Exponent's conclusions.

Exponent, Inc. is a leading engineering and scientific consulting firm with expertise in over 90 technical disciplines. Exponent has a full-time staff of over 900 located in 23 international offices. Exponent's multidisciplinary organization of engineers, scientists, physicians and business consultants, addresses complicated issues facing industry and government today. The firm's consultants provide product design analysis, development, and testing; analyze failures and accidents to determine their cause and prevent their recurrence; and evaluate environmental and human health concerns to find cost-effective solutions. Exponent is certified to ISO 9001 and is authorized by the General Services Administration (GSA) to provide professional engineering services. For information about Exponent capabilities and credentials visit www.exponent.com

Visual demonstrations of Toyota and Exponent testing, as well as detailed information regarding Toyota's electronic throttle control system operation and testing for electrical and electromagnetic interference can be found at www.toyotanewsroom.com.

Sequence and Nature of Artificially Manipulated Faults Unrealistic, Televised "Unintended Acceleration" Staged With Virtual Remote Throttle Control

TORRANCE, Calif., March 8, 2010 /PRNewswire/ - Today, during a live webcast, Toyota raised serious concerns about the validity, methodology and credibility of a demonstration of alleged "unintended acceleration" in a Toyota Avalon by Professor David Gilbert of Southern Illinois University and depicted in ABC News broadcasts and on-line segments.

A comprehensive analysis conducted by a world renowned engineering group, as well as testing by Toyota, has concluded the following about Professor Gilbert's demonstration:

The vehicle's electronics were rewired and reengineered in multiple ways, in a specific sequence, and under conditions that are virtually impossible to occur in real-world conditions without visible evidence.

Toyota vehicle electronic systems were actively manipulated to mimic a valid full-throttle condition.

Substantially similar results were successfully created in vehicles made by other manufacturers.

In the demonstration dramatized by ABC on February 22, Professor Gilbert, assisted by segment reporter Brian Ross, asserted that he had detected a "dangerous" flaw in the Toyota electronic control system that he alleged could lead to unintended acceleration. The following day, Professor Gilbert offered a preliminary report of his findings in testimony to the U.S. House of Representatives Energy and Commerce Subcommittee on Oversight and Investigations.

Engineers at Exponent, one of the country's leading engineering and scientific consulting firms, as well as Toyota engineers, have reviewed and recreated Gilbert's demonstration with substantially similar results in representative vehicles of other makes.

Separately, at Toyota's request, Dr. J. Christian Gerdes, associate professor of mechanical engineering at Stanford University and the director of the Center for Automotive Research at Stanford (CARS), conducted an independent review of Professor Gilbert's testimony and the preliminary report presented to Congress.

Their findings were demonstrated today at a news conference during which the accelerator circuitry of a Toyota Avalon, as well as a sampling of well-regarded and popular competitive makes, was rewired and manipulated as Gilbert did in his demonstration.

Kristen Tabar, general manager of electronics systems, Toyota Technical Center, summarizes three of the major concerns with the artificial nature of Professor Gilbert's demonstration.

"First, an electrical circuit that has been reengineered and rewired will not behave as it was originally designed and engineered," said Tabar.

"Second, no automaker can or should be expected to design detection strategies for artificially created events in the absence of any evidence that such an event can occur in the real world.

"Third, if the artificial condition created by Professor Gilbert had occurred in the real world, it would have left readily detectable fingerprints."

Exponent and Toyota engineers have found no evidence to suggest that any of the steps of Professor Gilbert's demonstration exists in the real world. Thus, the fact that the Toyota Avalon used by Professor Gilbert did not show a Diagnostic Trouble Code after his demonstration does not indicate an undetectable safety defect. The same is true of the representative vehicles of other manufacturers tested by Exponent and Toyota.

Professor Gilbert's reengineering and rewiring of the vehicle's electrical system involves the following manipulations in a specific sequence. First, the protective insulation on two separate wires that carry the accelerator pedal position signals to the Engine Control Module must be individually cut or breached. Next, these wires are connected to each other through a 200 Ohm resistor.

This contrivance, by itself, did not cause an increase in engine speed. To cause an increase in engine speed, it is necessary to cut the insulation on a third wire, the 5-volt power supply to the accelerator pedal, and force a low resistance connection between the power supply and the secondary signal wire.

The resulting increase in engine speed is a result of the subsequent artificial and sudden application of the 5-volt power supply to this signal line with the rewired circuit. When subjected to similar unrealistic reengineering and rewiring, the competitive vehicles evaluated by Exponent and Toyota achieved substantially similar results with varying levels of resistances.

This manipulation of electrical components and a power source created artificial voltages that the engine control module, or ECM, would interpret as valid accelerator pedal signals. In essence, this test created a virtual, remote control accelerator pedal that replicated the vehicle's own normally functioning accelerator pedal.

Also contrary to statements made in the ABC News story, had short circuits of the kind artificially created by Professor Gilbert occurred in real-world driving conditions, they would have left visible evidence such as damage or deterioration of the wiring and components.

As revealed in their testimony before Congress, Professor Gilbert's Preliminary Report was commissioned by Sean Kane, a paid advocate for trial lawyers involved in litigation against Toyota and other automakers. Mr. Kane also appeared on the ABC News broadcast in support of the claim that Professor Gilbert's demonstration revealed a flaw in the electronic throttle control system that could lead to "runaway" Toyota and Lexus vehicles. The relationship between Mr. Kane, Professor Gilbert and the trial lawyers who support Mr. Kane's advocacy was not revealed by ABC News during the newscast, nor was Toyota offered an opportunity to view the demonstration or given time to respond.

Toyota believes that the public and Congressional committees have been misled by Professor Gilbert's demonstration and the dramatization of it by ABC News. This has cast unwarranted doubt on the safety of Toyota and Lexus vehicles. Toyota remains confident in the integrity of the electronic throttle control system in its vehicles and there has been no reliable evidence of any kind to the contrary presented to the media or to Congress. Toyota's electronic systems have multiple fail-safe mechanisms to shut off or reduce engine power in the event of a system failure. Extensive testing of this system by Toyota has not found any sign of a malfunction that could lead to unintended acceleration.

Toyota has commissioned Exponent to conduct a comprehensive analysis of the electronic throttle control systems in Toyota and Lexus vehicles. No limitations of any kind were imposed on Exponent by Toyota. This evaluation is ongoing. An interim report of Exponent's findings has been provided to Congress and establishes the functionality of the electronic throttle control fail-safe systems. The final results of Exponent's exhaustive analysis will be made public when completed. As with all such reliable engineering analyses, Exponent's final results will provide the data and information necessary for others to validate Exponent's conclusions.

Exponent, Inc. is a leading engineering and scientific consulting firm with expertise in over 90 technical disciplines. Exponent has a full-time staff of over 900 located in 23 international offices. Exponent's multidisciplinary organization of engineers, scientists, physicians and business consultants, addresses complicated issues facing industry and government today. The firm's consultants provide product design analysis, development, and testing; analyze failures and accidents to determine their cause and prevent their recurrence; and evaluate environmental and human health concerns to find cost-effective solutions. Exponent is certified to ISO 9001 and is authorized by the General Services Administration (GSA) to provide professional engineering services. For information about Exponent capabilities and credentials visit www.exponent.com

Visual demonstrations of Toyota and Exponent testing, as well as detailed information regarding Toyota's electronic throttle control system operation and testing for electrical and electromagnetic interference can be found at www.toyotanewsroom.com.

Sign in to post

Please sign in to leave a comment.

Continue