Hyundai 2.4L Theta-II GDI - click above for high-res image gallery

When Hyundai's all new Sonata goes on sale early in 2010, it will arrive in U.S. showrooms with only one available engine, a thoroughly revamped version of the 2.4-liter Theta-II four cylinder. The new engine is Hyundai's first production powerplant with gasoline direct injection, but John Juriga, director of powertrains at the Hyundai-Kia Technical Center (HATCI), promised it wouldn't be the last. Juriga told attendees at a recent media briefing at HATCI that Hyundai was planning to roll out GDI across its lineup in the coming years.

For now, though, we have to be content with the new Sonata engine. The basic internal dimensions are carried over from the 2010 port injected edition, with bore and stroke of 88 mm x 97 mm for a total displacement of 2,359 cc. The new fuel delivery system has allowed the engineering team to bump the compression ratio from 10.5:1 up to 11.3:1. Like other direct injected engines, the charge cooling effect of injecting the fuel in into the high temperature compressed aid allows the elevated compression without the risk of knock. Read on to learn more about the first GDI Hyundai engine.

[Source: Hyundai]

Just as on the latest common rail direct injected diesels, the system on the Theta is capable of executing multiple fuel delivery pulses per ignition cycle. While all modern diesels uses multiple fuel pulses, this is a relatively new phenomena in gas engines. Hyundai is not the first to do it, with Ford's Ecoboost V6 and General Motors' 2.4-liter direct injected EcoTec using dual injection pulses during cold start periods. The split pulse strategy helps increase the exhaust temperature, to heat up the catalytic converter faster.

On modern engines, most of the emissions (aside from carbon dioxide that is produced whenever the engine is running) are produced immediately following a cold start. Since the catalyst is ineffective until it heats up, getting it warmed up fast is key to eliminating the remaining emissions. The changes to the GDI Theta help it to a 30 percent emissions reduction and a ULEV-2 and PZEV rating from the California Air Resources Board.

Besides direct injection, Hyundai has added several other enhancements to the four cylinder. A variable intake system speeds up the flow of air into the cylinders at low speed while reducing the restriction at higher speeds. Variable phasing is also implemented on both of the camshafts although the lift remains fixed. In combination with the increased compression ratio made possible by the DI all of this helps to the boost the torque which improves driveability. According to Juriga, the low end torque is increased by 7 percent while the improvement is as much as 12 percent at the upper reaches of the rev band.

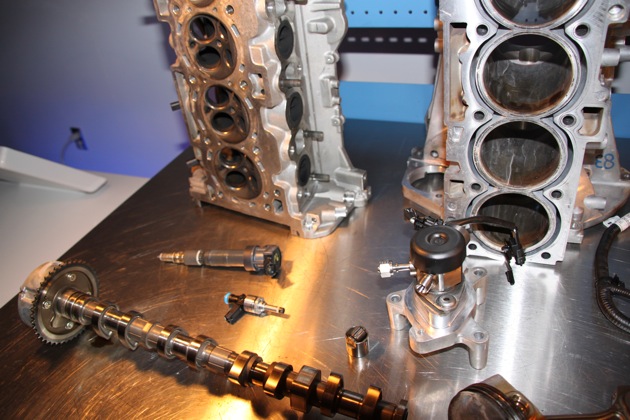

Maximum output of the GDI engine in the dual exhaust SE model is now 200 hp (198 hp in the single exhaust GLS and Limited models) at 6,300 rpm compared to 175 hp at 6,000 rpm in the 2010 model. Peak torque goes from 168 pound-feet to 186 pound-feet at 4,250 rpm. With Hyundai's emphasis on quality in recent years, the GDI four and all of the other engines being used in U.S. market cars are put through extensive testing including 300 hour durability cycles on the dynamometer. That's equivalent to 120,000 miles of driving at wide-open throttle. One of the Theta's that had already gone through this testing and had been torn down was on display adjacent to the cutaway engine.

Final EPA fuel economy numbers aren't yet available, but Hyundai is estimating a ten percent improvement. Hyundai officials made it clear that we could expect to see DI availability expanding in coming model years along with the addition of turbocharging and downsizing. The Theta-II GDI has been in production at Hyundai's Alabama engine plant for several weeks now and production of the new Sonatas will start shortly.

PRESS RELEASE:

HYUNDAI ANNOUNCES NEW ENGINE TO POWER ITS DRIVE TOWARD FUEL ECONOMY LEADERSHIP

SUPERIOR TOWNSHIP, Mich., 11/20/2009

Theta II 2.4-liter I-4 engine with Gasoline Direct Injection goes into production

* Built in Alabama, starting this week

* First Application in 2011 Sonata

* 10 percent better fuel economy and improved durability

* 200 horsepower and 186 lb-ft of torque

High Quality Photos for Print are available here: Large

A new four-cylinder engine will help power Hyundai's drive towards becoming the fuel economy leader when it launches in the company's most popular car, the 2011 Sonata.

Today, Hyundai unveiled the engine, which is built at Hyundai Motor Manufacturing of Alabama, at its Hyundai America Technical Center in Superior Township, Michigan, where it engineers, designs, tests and certifies vehicles sold in the U.S.

The 2.4-liter Theta II GDI engine features gasoline direct injection (GDI) technology which operates with greater efficiency using less fuel, creating fewer emissions and delivering improved throttle response, all while making more power than a traditional port-injected engine. In the all-new 2011 Sonata, consumers can expect an estimated best-in-class fuel economy of 35 miles per gallon in highway driving (EPA certification pending).

"At Hyundai's core is a promise to deliver unparalleled quality and value to our customers," says Hyundai Motor America President and CEO, John Krafcik. "Leading the introduction of this technology in our most important, highest volume product, the all-new 2011 Sonata, demonstrates our commitment to delivering products that excite and reward Hyundai owners."

Hyundai announced in late 2008 that it would lead the industry in meeting newly proposed Corporate Average Fuel Economy (CAFÉ) standards, that would have required a fleet average of 35 mpg by 2020, five years early through a combination of new technologies, including hybrids and gasoline direct injection. Since that time, the industry has agreed to work with the more aggressive standard. The Obama administration has since proposed more aggressive standards of 35.5 mpg by 2016, which Hyundai supports and also plans to meet ahead of schedule in its quest to become the most fuel efficient brand in the U.S.

Theta II 2.4L GDI

Hyundai's Theta I-4 engine family is a proprietary design, engineered in Namyang, Korea and currently in production for applications all over the world at volumes exceeding 2 million annually. The new Theta II 2.4L GDI engine is a derivative of the Theta with major upgrades in technology and architecture. It features a unique block, valvetrain, front end accessory drive (FEAD), intake manifold, pistons, rods, crankshaft, variable induction system and catalyst. The Theta II 2.4L GDI delivers an estimated 200 horsepower @ 6,300 rpm and 186 lb.-ft. of torque @4,250 rpm. The most significant technology in the new engine is direct injection.

How GDI Differs from Conventional Port Injection

The key to direct injection is the use of individual fuel injectors for each cylinder strategically positioned to deliver the optimal fuel charge directly into the combustion chamber. In a traditional multi-port system, gasoline is delivered via the port of each cylinder, where it mixes with air and is drawn into the cylinders when the intake valve opens and the piston moves down. A drawback to the traditional system is when engine speeds increase, the time to open the valve to deliver fuel becomes progressively shorter making accurate delivery more challenging.

GDI avoids that issue and the shorter, more direct path of fuel delivery, allows for greater control of the optimum fuel mixture at the optimum moment, thus improving efficiency.

The fuel is injected by a camshaft-driven, high pressure pump that operates at pressures up to 2175 psi (150 bar). Direct injection also utilizes a higher than normal 11.3:1 compression ratio to for increased power. The pistons are "domed" to increase combustion efficiency.

The injection is split into two phases to achieve optimum combustion during the catalyst heating operation right after the cold start. First, the pilot injection is applied during the piston's descent in the intake stroke and then, in the second, at the end of the compression stroke, the rest of the fuel is injected and then ignited after some delay. This split-injection technique reduces loading on the catalytic converter and helps lower emissions.

When an engine is cold, so is the catalyst. Traditional engines run high rpm's for a few seconds upon startup to "fire" the catalysts. The GDI's split-injection strategy enables the catalyst to reach operating temperature faster. This helps reduce emissions by 30 percent during cold starts meeting California Air Resources Board's ULEV-2 and PZEV standards.

Dynamic Performance and Fuel Economy Improved

Compared to a conventional engine of the same displacement, GDI delivers 7 percent more torque at low engine rpm's and 12 percent more torque at the high-end for better take-off and overtaking performance. Best of all, GDI boosts gas mileage by up to 10 percent compared to a conventional engine.

Variable Induction System (VIS)

Design modifications in the Theta-II 2.4L GDI engine continue with a 2-stage variable induction system which improves engine breathing by automatically adjusting the volume of the air drawn into the combustion chamber to create the optimal air-to-fuel mix under different engine load conditions.

Continuously Variable Valve Timing (CVVT)

Depending on engine load and speed, CVVT can modulate the phasing of the valve opening and closing for more power and lower emissions. The new Continuously Variable Valve Timing System improves engine breathing on the intake and exhaust sides for better fuel economy and lower emissions. And the CVVT system is run by a new steel chain with an innovative roller and a retuned chain tensioner for the improved fuel efficiency and robust durability.

Weight and Friction Reduction

A critical engineering challenge is to find ways to reduce engine weight and internal friction to attain better fuel economy. Friction reduction measures in the Theta II 2.4L GDI include a revision of the piston pin from a fixed-type to a full-floating design which helps reduce friction between piston and cylinder wall. This further improves long-term durability.

And under the piston crown, engineers have added a piston cooling jet which sprays a fine oil mist to the bottom of the piston reducing heat and contributing to the durability.

Weight reduction measures include a new lighter-weight aluminum cylinder block and a lighter weight crankshaft. Hyundai engineers looked for weight savings throughout the engine, inside and out. In the end, the Theta-II 2.4L GDI is more than10 pounds lighter than its predecessor.

Next Steps?

Hyundai has stated aggressive goals aiming at fuel economy leadership. The benefits of GDI technology will be expanded over time to the entire family of Hyundai gasoline engines. GDI is one technology out of several that will help deliver superior efficiency, durability, quality and value to Hyundai customers.

HYUNDAI MOTOR AMERICA

Hyundai Motor America, headquartered in Fountain Valley, Calif., is a subsidiary of Hyundai Motor Co. of Korea. Hyundai vehicles are distributed throughout the United States by Hyundai Motor America and are sold and serviced through more than 790 dealerships nationwide. All Hyundai vehicles sold in the U.S. are covered by The Hyundai Advantage, America's Best Warranty. In addition, Hyundai Assurance is now offered on all new vehicles leased or purchased from a certified Hyundai dealer. The program is available to any consumer, regardless of age, health, employment record or financed amount of the vehicle. The program is complimentary for the first 12 months.

ABOUT HYUNDAI AMERICA TECHNICAL CENTER, INC.

Hyundai America Technical Center, Inc (HATCI), headquartered in Superior Township, Michigan, near Ann Arbor, is a subsidiary of Hyundai Motor Co. of Korea. HATCI provides design and engineering support and tests and certifies all Hyundai (and subsidiary Kia) products sold in North America. In addition to the headquarters in Michigan, HATCI operates two design centers in Irvine, Calif., two engineering facilities in Irvine and Chino, Calif. and the Hyundai California Proving Ground in California City.

Sign in to post

Please sign in to leave a comment.

Continue