Click on the Equinox Fuel Cell for a high res gallery

In the fall of 2006, General Motors announced plans to launch the largest ever field test of hydrogen fuel cell vehicles with Project Driveway. The intent was to build over 100 fuel cell-powered Chevrolet Equinoxes and provide them to regular drivers to use for a period of time in real world conditions so that the company could gather data about the vehicles perform. Everything in the article below applies equally to the Equinox fuel cell and the HydroGen4 which is the re-badged version for Europe. Only the name is different.

Having significant numbers of regular customers drive your vehicles is very different from having engineers drive them. Most importantly, they will tend to see a much wider variation of both road and driver input conditions than you will ever see on a proving ground. When a vehicle is being developed usually at most only a few dozen people responsible for each of the systems, like power-train, brakes, chassis, body, etc., will ever spend any significant amount of time driving them. Those engineers tend to focus on what they know to be the likely problem areas and get those fixed.

Continue reading after the jump

Inevitably, no matter how much internal testing is done, when a vehicle gets into the hands of regular customers, new issues will crop up. Those problems get fed back to the engineers and they add them to the list of things to look at on the next go around. That's what Project Driveway is all about. With internal combustion engines, over a century of experience has given development teams a pretty good of what to expect in the field. The scope of knowledge with fuel cells and hydrogen fueling is much more limited. In the few field tests that have been conducted so far by companies like Ford, DaimlerChrylser and Honda, the companies are all trying to gain a competitive advantage with fuel cells.

In Project Driveway some of the vehicles will go to controlled fleets. Many of them however will go to ordinary people who happen to live in proximity to where there is some hydrogen fueling infrastructure already in place. Anyone can go to the eligibility website and enter their zip code. If you live in one of the test areas in southern California, New York or Washington DC you can than apply for the program. People who are accepted will get one of the Equinoxes for a period of time along with free hydrogen in return for the feedback they provide to GM.

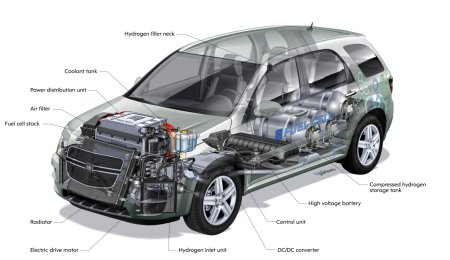

So what is this fuel cell Equinox/HydroGen4? It's based on the body-in-white and suspension of a standard Equinox. The underside of the Equinox has been modified to accommodate the new power-train and energy storage system. One of the design goals was to make the packaging as transparent as possible to drivers and limit the intrusion into the cargo and passenger space.

The entire fuel cell stack/inverter/controller/motor system is packaged to fit into the space within the standard Equinox engine compartment. Just like a standard internal combustion power-train, the fuel cell/electric drive system is assembled to the front sub-frame and suspension off-line and then installed into the vehicle from the below. Once it's in place, the hydrogen fuel lines, high-voltage lines to the battery and other assorted connections are hooked up.

Under the floor in the middle of the vehicle there is a nickel metal hydride battery pack. The pack has a capacity of 1.8kWh and an output of 35kW. It's used to store kinetic energy from the regenerative braking system and provide an extra boost when needed for acceleration. Continuing back below the rear seats and cargo area are three hydrogen storage tanks. The tanks are made of carbon fiber composite and they contain hydrogen gas pressurized to 10,000 psi.

The previous HydroGen3 was based on the European Opel Zafira van and was built in two different versions. One used compressed hydrogen gas at 5,000 psi while the other used liquid hydrogen. For hydrogen to be in liquid form it needs to be kept below -253°C. Like the BMW Hydrogen 7, the liquid H2 version used a heavily insulated tank but even with the best insulation the fuel does warm up over time. When the liquid warms it vaporizes and the vapor has to be vented to atmosphere. If the vehicle is left sitting long enough the fuel will completely boil off. While liquid hydrogen is more dense than the compressed gas, until a means is developed to keep it cold indefinitely, it won't be a viable option.

In light of the issues with liquid H2, GM has chosen to go with gaseous hydrogen for now. There are three tanks so that each one can be smaller in diameter providing for less overall intrusion into the interior of the vehicle. Other converted production vehicles like the Ford Focus FCV use a single large tank that takes up virtually the entire trunk volume. The fuel cell Equinox has a small lump on the floor of the cargo area where the rear-most tank is but the cargo capacity remains at 32 cu.ft compared to the 35.2 cu.ft of the standard Equinox. Seating space remains the same as stock although the rear seat is now for two only with the center position occupied by a storage bin.

The hydrogen tanks contain a total of 4.2 kg of hydrogen. which is enough to give the Equinox a range of 200 miles, about the same as the Focus FCV. Of course it goes without saying that your mileage may vary. Predominantly urban driving may increase the range thanks to some regen and highway driving may cause a dip. The braking system is capable of blending conventional hydraulic friction braking and regenerative braking in a seamless manner. In addition to regenerative braking the system can also provide full slip control capability including anti-lock braking, traction control and stability control.

Like the system on the upcoming Two-Mode hybrids, the system determines how much regen braking energy the battery can absorb and then reduces the friction braking torque by that amount. Once the battery reaches its maximum state of charge the regenerative braking is reduced to zero and the system returns to full friction braking. In the GM mild hybrid system the regenerative braking is overlaid on the friction braking. When the battery reaches full charge, the regen is switched off and the vehicle decel suddenly changes. In the Equinox there is no noticeable change in deceleration.

The fuel cell stack is based on GM's fourth generation technology just like the Chevy Sequel concepts. The Equinox will be the final vehicle to use this design as GM's fuel cell team is already well on their way developing the generation 5 stack which will go into the fuel cell version of the Volt sometime next year. The Gen4 stack is designed to operate at temperatures from -13F up to 113F meaning that it can be operated in most regions of the United States and Europe without a heating mechanism.

The Gen3 stack used a screw type compressor to pump air into the fuel cell but the new stack uses an electrically driven turbo compressor which is both quieter and more efficient. Since the fuel cell itself doesn't produce any noise, components like the compressor and motor are the main sources of noise. The stack has an output of 93kW (125hp) which is enough to push the 4431 lb-Equinox from to 60 mph in 12 seconds and on to a top speed of 100 mph. The electric traction motor has a continuous output of 73 kW with peaks up to 94 kW. Torque of 236 lb-ft is available pretty much from a stand-still and the motor sends power directly to the differential with no transmission.

Accessories like power steering and air conditioning are electrically driven with the heating supplied by the stack cooling system. The interior of the Equinox is pretty much stock Equinox with the addition of a touch screen display in the center stack for the navigation system and power-flow display. The Equinox is also equipped with front and side curtain airbags. On the outside the main visual difference is at the front where the fascia is based on the one from the Pontiac Torrent with the now standard Chevrolet horizontally split twin port grille and extra cooling air inlets in the lower front corners. At the back the fascia under the rear bumper has been replaced with one featuring four thin vertical slats in place of the standard exhaust pipe where the steam exhaust from the fuel cell comes out.

Driving the fuel cell Equinox should be pretty much the same as any standard front-wheel drive internal combustion version carrying an extra 770 lbs. As final development for the Project Driveway program was happening this summer GM was also in the process of moving about 500 of the 600 people who have been working on fuel cell activities from the research and development side of the company to production engineering and vehicle integration. In that capacity, the scientists and engineers will be working to bring the latest fuel cell technology to full production readiness.

Sign in to post

Please sign in to leave a comment.

Continue