We've all got the standard wares of the trade: wrenches (open end and box), sockets (inch, metric, regular and deep), various and sundry screwdrivers, etc. Those things are expected when building a tool kit. In the years since I started wrenching on cars with a simple Craftsman kit, I have done a lot of supplementing. No longer do my tools fit in the small box they came in. The box has long since broken, anyway. My heavy junkyard prowling days are behind me, but they helped me develop a deep love for some of my tools. Usually it's the ones that help me take stuff apart easily, or put things back together correctly.

Check the top five after the jump.

Torch

One of my favorite tools is a MAPP-gas torch. It's compact, so it fits easily in the Stanley rolling tool box. I have used the torch to heat countless recalcitrant fasteners, usually on suspension components. MAPP gas is hotter than propane, though not as hot as an Oxy-Acetylene kit. That'd be another thing to lug, as Oxy-Acetylene kits are considerably larger than the little plumbing torches. There's a MAPP/Oxy setup, but it's halfway useless. You burn through the oxygen just about the time you really start making progress. Oh well.

One of my favorite tools is a MAPP-gas torch. It's compact, so it fits easily in the Stanley rolling tool box. I have used the torch to heat countless recalcitrant fasteners, usually on suspension components. MAPP gas is hotter than propane, though not as hot as an Oxy-Acetylene kit. That'd be another thing to lug, as Oxy-Acetylene kits are considerably larger than the little plumbing torches. There's a MAPP/Oxy setup, but it's halfway useless. You burn through the oxygen just about the time you really start making progress. Oh well.

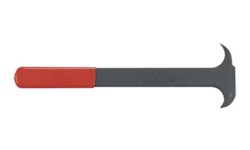

Seal Puller/Big Sockets

Another tool that I'm glad I bought is a seal puller. Seems simple, stamped steel with a rubber boot at the handle end, hook shaped. For years, I'd dig seals out gingerly with small screwdrivers, terrified I was going to mar the hell out of the shaft or the housing. With the seal puller, it's quick - stick and lever. Out pops the seal. Which leads me to the next few pieces I really dig having around: big sockets. It's not often I'm faced with a 30mm fastener, but that socket makes a dandy drift for installing seals.

Another tool that I'm glad I bought is a seal puller. Seems simple, stamped steel with a rubber boot at the handle end, hook shaped. For years, I'd dig seals out gingerly with small screwdrivers, terrified I was going to mar the hell out of the shaft or the housing. With the seal puller, it's quick - stick and lever. Out pops the seal. Which leads me to the next few pieces I really dig having around: big sockets. It's not often I'm faced with a 30mm fastener, but that socket makes a dandy drift for installing seals.

Thread Chase

I almost never use it to chase spark plug threads, which is the intended use. I've never had the pleasure of stripped or damaged spark plug holes in my cars. It turns out that the thread on some oxygen sensors is the same as some spark plugs. Exhaust components always get a coating of oxidation, and the bung for the O2 sensor is no different. Oxygen sensors are sometimes murder to remove, and putting the new one into that beat up, heat cycled bung is no picnic, either. I usually pull out the chase and clean up the threads before attempting to screw in the new sensor.

I almost never use it to chase spark plug threads, which is the intended use. I've never had the pleasure of stripped or damaged spark plug holes in my cars. It turns out that the thread on some oxygen sensors is the same as some spark plugs. Exhaust components always get a coating of oxidation, and the bung for the O2 sensor is no different. Oxygen sensors are sometimes murder to remove, and putting the new one into that beat up, heat cycled bung is no picnic, either. I usually pull out the chase and clean up the threads before attempting to screw in the new sensor.

Digital multimeter

The DVOM is handy for watching real-time dynamic changes. With the DVOM, I can use the continuity function to trace wiring connections, check voltage drop or amperage draw as well as test individual sensors. My favorite use was to tweak the adjustable voltage regulator in my old 740 to 14.5V; the H4's would burn nice and bright. When checking the operation of an oxygen sensor, the DVOM and its fast response are especially handy. It's a neat trick to tune an older engine with an O2 sensor and meter, though there's something more romantic about doing it by ear.

The DVOM is handy for watching real-time dynamic changes. With the DVOM, I can use the continuity function to trace wiring connections, check voltage drop or amperage draw as well as test individual sensors. My favorite use was to tweak the adjustable voltage regulator in my old 740 to 14.5V; the H4's would burn nice and bright. When checking the operation of an oxygen sensor, the DVOM and its fast response are especially handy. It's a neat trick to tune an older engine with an O2 sensor and meter, though there's something more romantic about doing it by ear.

Ratchet Adapter

I used this one just tonight, swapping the snow tires onto the car (why did I wait until it was in the single digits?) before the snow flies on Friday. This thing is one of my very favorite tools. It allows me to get more than 4 positions out of my breaker bar or torque wrench, facilitating easier, faster operation. I love this thing. By far, one of my favorite. tools. ever.

I used this one just tonight, swapping the snow tires onto the car (why did I wait until it was in the single digits?) before the snow flies on Friday. This thing is one of my very favorite tools. It allows me to get more than 4 positions out of my breaker bar or torque wrench, facilitating easier, faster operation. I love this thing. By far, one of my favorite. tools. ever.

But Wait, There's More

I've got more things that I use all the time, but they're not quite tools. The insulated coveralls fall into that category. I have no garage (yet), so any wrenching I do in the winter is cold. The coveralls help. I always have a box of latex or nitrile gloves in the toolbox, as well. My fingers are no longer numb for three days after working on stuff, and I don't get black gunk under my fingernails. One of my most indespensible tools is a Sharpie. With it, I can index pieces, so I reassemble them in proper orientation, mark the inner lip of my rims so when the monkey boys at the dealer rotate my tires (when I've told them not to), I know where they go, and it's most handy for angle-tightening. Draw a mark on the fastener head, draw a "destination" mark at the angle necessary, turn. Way easier than one of those fancy protractor things or fiddling with pieces of cardboard.

I'm sure we've all got some "ninja-grade" bits in our toolboxes, I'd love to be turned on to new toys. It helps me build my Christmas list, and gives me an excuse to go out and listen to all the podcasts I never have time to get to.

Sign in to post

Please sign in to leave a comment.

Continue