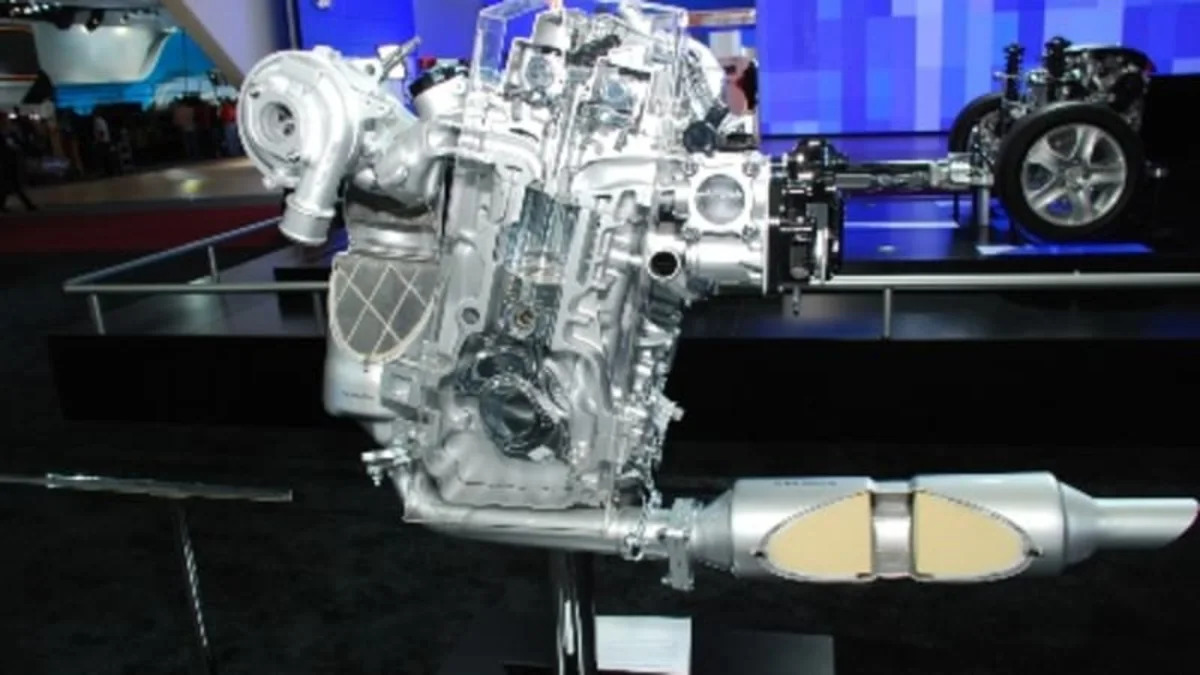

We've been hearing about Honda's upcoming clean diesel for quite some time now, and the automaker was kind enough to show a cutaway of the i-DTEC clean diesel for us at the 2008 Detroit Auto Show. Expect to see the engine appear first in an upcoming and unnamed Acura product around 2009 - but while you may have to wait over a year for the engine, you can see some cutaways of it right now in our photo gallery below. Click past the jump for some brief commentary on what we learned about Honda's i-DTEC clean diesel in Detroit.

Up top, we find centrally-located injectors that are surrounded by four valves - no surprise. Note the extremely tight valve angle, and the roller-equipped rockers that enable this geometry. Valve lash is controlled via the small plungers that appear on the outside perimeter of the head, opposite the valves.

The common rail for fuel is shown at the bottom of this photo, with individual feed pipes to the injectors. We are currently unaware as to what injector technology is being employed by Honda, but various presentations by Denso have us believing that it's likely piezoelectric technology, with multiple pre- and post-combustion injection events utilized to reduce emissions and noise.

The bottom end is smaller than what we're used to seeing on diesels, but then again this isn't a 6+ liter monster intended for a heavy-duty pickup. The piston skirts are considerably longer than what we'd see on a spark-ignition engine of this size, and the top piston ring is located quite some distance from the piston crown (this improves the strength of the piston and helps prevent the ring from getting pinched in its groove during the incredibly high peak pressure of diesel combustion).

Shockingly enough, we saw no evidence of variable-vane technology employed on the turbocharger. Perhaps this is intended to reduce cost?

An electromechanical exhaust gas recirculation (EGR) valve is used to regulate the amount of exhaust gas that is allowed back into the intake manifold. Such gas is inert; when combined with the intake charge during part-throttle operation, it helps reduce the amount of free oxygen in the combustion chamber. This, in turns, helps reduce the formation of oxides of nitrogen (NOx) - one of the nastier by-products of diesel combustion.

Tucked underneath the intake manifold is the EGR cooler, which, as the name implies, takes the hot exhaust gases and cools them considerably before recirculating them into the intake manifold. Diesels employ far greater volumes of EGR than do gasoline engines, so cooling becomes important to avoid excessively high charge air temperatures.

Typical for modern diesels, an electronically-controlled throttle butterfly is placed in the intake tract. It's not for controlling the engine's speed, however; instead, it creates a bit of vacuum to help draw EGR gases into the intake manifold.

Immediately after leaving the turbocharger, exhaust gases are subjected to an oxidizing catalyst to turn hydrocarbon and carbon monoxide emissions to carbon dioxide. Particles that make it through the oxidization process are captured by the particulate filter. This particular filter shows no provisions for a burn-off mechanism; we're not sure if this is a production-intent design and how maintenance-intensive the device may be.

This downstream emissions device would appear to be a lean NOx storage catalyst, which is employed to capture, store, and reduce oxides of nitrogen before they enter the atmosphere. NOx is stored during lean modes of operation; on occasion, the engine runs rich to provide the catalyst with an opportunity to reduce the nitrates to inert nitrogen.

According to manufacturers and suppliers, this approach makes sense on small diesels where the fixed cost of a complex urea injection system is cost-prohibitive. At some point, engine size (and thus catalyst size and cost) increases to the point where urea injection is cheaper.

Sign in to post

Please sign in to leave a comment.

Continue