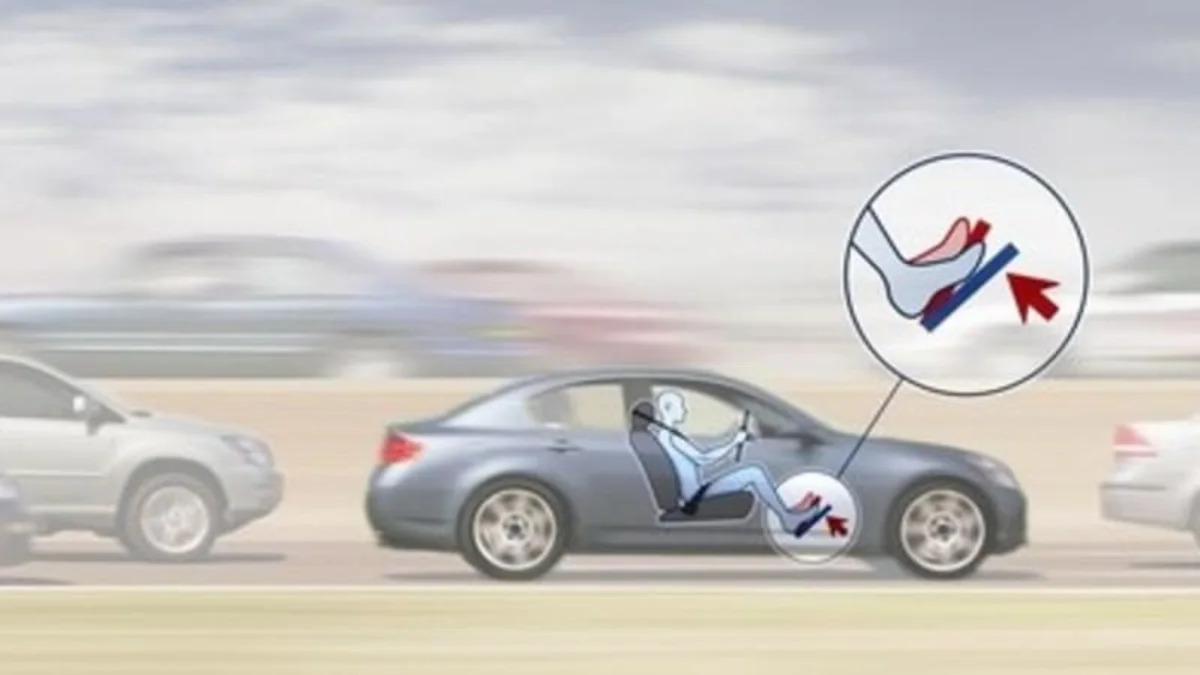

Video game players are used to force feedback controllers that provide a haptic response to user inputs. German automotive supplier Continental is now introducing an accelerator pedal that provides similar feedback to drivers in cars. The Accelerator Force Feedback Pedal (AFFP) is being initially branded as a safety device with interfaces to stability control and adaptive cruise control systems. The idea is when other active safety systems in the vehicle detect a hazardous situation where the drive should slow down, the pedal vibrates or buzzes to provide a signal to the driver to back off. The system can also be used monitor the driver's acceleration behavior and provide warnings if they are accelerating too hard or too often. Much like the efficiency gauges now being installed in many new cars, the active pedal can help the driver learn the most efficient driving techniques. An electric motor on the underside of the pedal pushes the pedal back against the driver's foot, but the driver can still push through if they decide they really need to accelerate.

[Source: Continental Automotive]

Continental produces the first accelerator pedal that communicates with the driver

Continental's Accelerator Force Feedback Pedal reaches market production for the first time – aims at significantly reducing the number of accidents

Frankfurt am Main, Germany, August 11, 2008. The accelerator pedal, now being installed by a Japanese car manufacturer, represents a unique safety engineering technology which the Chassis & Safety Division of Continental, the international automotive supplier, is introducing to the world's markets for the first time. The Accelerator Force Feedback Pedal (AFFP) gives warning of hazardous situations by vibrating and exerting counter pressure in the accelerator pedal. This should make the driver take his foot off the pedal and get ready to brake. This technology is an extension to Continental's ContiGuard® safety system and represents a further contribution to reducing the number of road traffic injuries, particularly as a result of rear-end collisions. The intelligent accelerator pedal can also help the driver to drive at a more even speed and therefore more economically with the aim of reducing fuel consumption and CO2 emissions.

Direct support for the driver

The most important question in every interaction between the driver and the vehicle is how to warn the driver of a hazardous situation and make them fully aware of the information provided. "The basic problem with optical or acoustic signals is that the driver's attention might be elsewhere, either because he/she is on the phone or chatting to a passenger, for example, and as a result fails to note the warning", says Bernd Gebhart, head of the Chassis Electronics business unit. The AFFP relies on warning the driver directly through sensory stimulation; the hazard warning is felt directly by the driver's foot, making him aware of the situation in the quickest and most reliable way so that he can react.

Continental also uses similar sensory warnings, for example in its lane-change assistant where vibrations in the steering wheel warn against pulling out to overtake if a vehicle is coming up from behind in the fast lane. The AFFP vibrates if the Adaptive Cruise Control (ACC) senses that the vehicle is too close to the vehicle in front. In hazardous situations, the system significantly increases the counterpressure on the accelerator pedal.

However, the driver still remains in control and can accelerate if required by the specific traffic situation.

By integrating AFFP into future vehicle systems, the active accelerator pedal could make a valuable contribution to vehicle safety in a variety of dangerous situations. If a breakdown or an accident occurs where visibility is restricted and if this is reported electronically by Car-2-Car communication, the AFFP will respond – and similarly if the sensors in the vehicle register that the driver is clearly struggling not to fall asleep. "This sensory warning at the accelerator pedal, the classic man-machine-interface, is a clear road safety gain", stresses Gebhart.

A rapid reaction accelerator pedal: the electric motor takes 0.1 seconds to react

The central mechanical feature of the Accelerator Force Feedback Pedal is an electric motor, directly linked to the accelerator pedal, without any additional working parts, and in a very short reaction time adjusts the pedal position: the motor can affect the pedal position within 0.1 seconds of responding. The drive is a one-way design; i.e. the motor only turns in release direction.

The Accelerator Force Feedback Pedal can be installed in any vehicle, being suitable for both suspended and floor-mounted pedals. This means that the AFFP can also be used for small vans and commercial vehicles – inadequate distance between vehicles and overtired drivers are the most frequent causes of accidents with both vans and trucks.

Smooth traffic flow reduces fuel consumption and CO2 emissions

Even in heavy traffic, the Accelerator Force Feedback Pedal helps drivers to maintain optimum vehicle distance and to drive at a consistent speed. The system uses information from the radar or camera sensors, identifies the best speed for staying with the flow of the traffic, and warns the driver by gentle pedal counterpressure that if they were to accelerate any more, the driver would be exceeding the optimum speed range and distance. The result is that the vehicle keeps to an even engine speed, avoiding frequent braking and accelerating. This not only spares the driver's nerves and therefore reduces the risk of accidents, it also noticeably reduces fuel consumption and, consequently, CO2 emissions.

Almost every other accident is a rear-end collision

The statistics for passenger car rear-end collisions in 2006 are clear testimony:

USA: 20% (Source: NHTSA, National Highway Traffic Safety Administration)

Europe (Focus on Germany): 44% (Source: Federal Highway Research Institute (BASt))

Japan: 57% (Source: Institute For Traffic Accident Research and Data Analysis (ITARDA))

These accidents are largely attributable to the human factor. In 85% of cases, human error was a decisive determinant of the accident; the three most important aspects being:

Inappropriate speed

Inadequate vehicle distance

Insufficient attention.

The Accelerator Force Feedback Pedal now offers the opportunity of intervening to achieve the globally stated aim of lowering the number of traffic fatalities by half.

With targeted annual sales of more than €26.4 billion for 2008, the Continental Corporation is one of the top automotive suppliers worldwide. As a supplier of brake systems, systems and components for the powertrain and chassis, instrumentation, infotainment solutions, vehicle electronics, tires and technical elastomers, the corporation contributes towards enhanced driving safety and protection of the global climate. Continental is also a competent partner in networked automobile communication. Today, the corporation employs approximately 150,000 people at nearly 200 locations in 36 countries.

As a worldwide leading technology and systems partner to the automotive industry, the Chassis & Safety Division of Continental AG integrates extensive know-how and leading-edge quality in the fields of active and passive driving safety, safety and chassis sensorics, and chassis components. The Division achieves sales of more than € 5 billion (based on 2006 figures) with a workforce of more than 27,500 (2007). Chassis & Safety develops and produces electronic and hydraulic brake and chassis control systems, sensors, driver assistance systems, air bag control systems, occupant classification systems, washer systems as well as electronic air suspension systems.

Sign in to post

Please sign in to leave a comment.

Continue