When Acura designed the RDX, they wanted to give it a lightweight mill that was powerful enough to compete in a class rife with six-cylinder power. A V6 would provide the desired output, but it would add too much mass over the front axle, so instead, Acura decided to slap a turbo onto a four-cylinder and boost output accordingly. Honda, Acura's parent company, has developed some of the best performing four bangers in terms of horsepower-per-liter, so the engineers had a lot of innovation at their fingertips. The package put together for the RDX is a 2.3-liter inline-four, complete with Honda's i-VTEC variable valve timing and creating 240 hp at 6000 rpms and 260 ft-lbs of torque at 4500 rpm. Thanks to the addition of the turbocharger, it makes more torque than any other engine in Acura's lineup -- not a huge feat considering that most of Honda/Acura engines are devoid of any low-end grunt. The engine also features some economical innovations to keep the RDX's price tag from skyrocketing, so when we found this engine on display at the Acura booth at the 2007 Los Angeles Auto Show, we thought a closer look was in order. Follow the jump for an in-depth view with pictures from the display engine and Acura's own renderings.

Using a small four-cylinder, as opposed to a V6 engine configuration, has a significant advantage when it comes to meeting emissions standards. The RDX mill meets CARB LEV II ULEV (ultra low emissions vehicle) along with EPA Tier-2 Bin-5 standards. The reduction of hydrocarbons is achieved by placing the catalytic converter as close as possible to the turbine outlet of the turbocharger. This enables the cat to heat up quickly so it can do its job of converting hydrocarbons and carbon monoxide into carbon dioxide and water, along with breaking up NOx. The engine's cylinder head is also designed with internal exhaust gas recirculation. This significantly reduces the occurrence of NOx emissions by lowering temperatures in the combustion chamber that lead to the generation of nitrogen oxide and nitrogen dioxide.

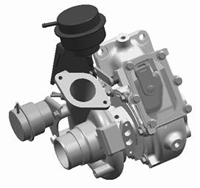

Certainly the most impressive development of Acura's 2.3L engine is the design of the turbocharger turbine manifold. The manifold has a variable geometry arrangement that doesn't involve a lot of complication. This design has similar benefits to the variable-vane turbocharger used by Porsche, but not as costly or intricate to implement. Variable turbine geometry allows the turbocharger to perform over a wider range of exhaust flow rates. As engine rpm increases so does the air flow rate through the engine and out the exhaust. If a turbocharger turbine manifold is sized to flow for maximum horsepower, then the engine must reach a certain level of rpms before enough exhaust gas is circulating through the manifold for its energy to be effectively recovered by the turbine wheel of the turbocharger. By reducing the area ratio (A/R) of the turbine manifold, the turbine wheel can begin to effectively recover exhaust gas energy at lower rpms. However, the smaller size manifold begins to restrict the flow as rpms increase. This in-turn limits the amount of power the engine can produce. To solve the problem Acura created a variable flow turbine manifold that has multiple flow paths for exhaust gas.

Certainly the most impressive development of Acura's 2.3L engine is the design of the turbocharger turbine manifold. The manifold has a variable geometry arrangement that doesn't involve a lot of complication. This design has similar benefits to the variable-vane turbocharger used by Porsche, but not as costly or intricate to implement. Variable turbine geometry allows the turbocharger to perform over a wider range of exhaust flow rates. As engine rpm increases so does the air flow rate through the engine and out the exhaust. If a turbocharger turbine manifold is sized to flow for maximum horsepower, then the engine must reach a certain level of rpms before enough exhaust gas is circulating through the manifold for its energy to be effectively recovered by the turbine wheel of the turbocharger. By reducing the area ratio (A/R) of the turbine manifold, the turbine wheel can begin to effectively recover exhaust gas energy at lower rpms. However, the smaller size manifold begins to restrict the flow as rpms increase. This in-turn limits the amount of power the engine can produce. To solve the problem Acura created a variable flow turbine manifold that has multiple flow paths for exhaust gas.

Acura's variable flow turbine manifold works much like a traditional twin-scroll turbine housing. A twin-scroll turbine housing has a divider in the center of the exhaust flow path. It works with exhaust pulses by keeping the exhaust flow of consecutive cylinders separate in order to capture more of the exhaust gas energy. However, Acura utilized this design differently. They created a diaphragm actuator-controlled trap door that restricts the exhaust gas to one scroll at lower rpms, then flips away to allow the gas to flow through both scrolls at higher rpms. It can be seen as the red painted flap on the display engine. This design allows the small engine to make use of its entire exhaust flow at low rpms, as opposed to a traditional twin-scroll design that only feeds half the exhaust through each scroll.

Acura's variable flow turbine manifold works much like a traditional twin-scroll turbine housing. A twin-scroll turbine housing has a divider in the center of the exhaust flow path. It works with exhaust pulses by keeping the exhaust flow of consecutive cylinders separate in order to capture more of the exhaust gas energy. However, Acura utilized this design differently. They created a diaphragm actuator-controlled trap door that restricts the exhaust gas to one scroll at lower rpms, then flips away to allow the gas to flow through both scrolls at higher rpms. It can be seen as the red painted flap on the display engine. This design allows the small engine to make use of its entire exhaust flow at low rpms, as opposed to a traditional twin-scroll design that only feeds half the exhaust through each scroll.

Other elements of the engine design can be seen in the cutaway photos, such as the top mount intercooler. Be sure to visit the gallery for a host of high-res images to get a better look.

Sign in to post

Please sign in to leave a comment.

Continue