We've now had a couple of weeks to digest the new 620+hp LS9 V8 in the Corvette ZR1, it's time to see what else the GM Powertrain team has up its sleeves. The other half of the GM power duo to be displayed at the 2008 North American International Auto Show is the 2009 Cadillac CTS-V. The CTS-V is propelled by an engine closely related to the LS9 and carrying the designation LSA.

Like the LS9, the LSA is an aluminum block 6.2L V-8 with an Eaton 6th generation two-rotor supercharger. The basic configuration matches the LS9 with the blower sitting in the valley of the block. An air to liquid intercooler sits on top of the supercharger. Differences between the two engines are primarily intended to give the Cadillac an extra air of refinement compared to the sports car and result in the LSA "only" producing 550 hp and 550 lb-ft of torque. Read on after the jump to learn about the differences between the LS9 and LSA.

[Source: General Motors]

Like the LS9, the LSA is an aluminum block 6.2L V-8 with an Eaton 6th generation two-rotor supercharger. The basic configuration matches the LS9 with the blower sitting in the valley of the block. An air to liquid intercooler sits on top of the supercharger. Differences between the two engines are primarily intended to give the Cadillac an extra air of refinement compared to the sports car and result in the LSA "only" producing 550 hp and 550 lb-ft of torque. Read on after the jump to learn about the differences between the LS9 and LSA.

[Source: General Motors]

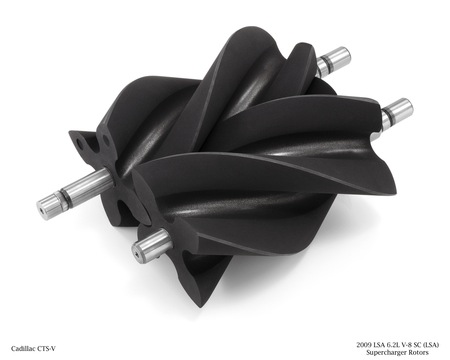

The single biggest difference leading to lower output for the Cadillac is the supercharger displacement. While the LS9 has a 2.3L blower, the unit in the CTS-V only displaces 1.9L. Aside from the size, the blower is based on the same four lobe rotor design with 160 degrees of twist to the lobes. The design provides greater efficiency and thirty-five percent less power draw than the previous three lobe design in addition to much quieter operation. The maximum boost pressure is reduced from 10.5 psi to 9.0 psi.

Since the CTS-V had a little more vertical and longitudinal space under the hood than the Corvette, the engineers were able to use a different intercooler. The LS9 intercooler has two separate heat exchanger units that are split on either side of the supercharger outlet. The LSA has a single heat exchanger that is slightly taller but has more efficient airflow. The other packaging difference is the use of a third drive belt dedicated to the supercharger rather than the two belt system used on the ZR1 engine.

The lower pressures mean that some of the material changes that were implemented on the LS9 were not necessary on the LSA. The titanium connecting rods and intake valves are replaced by forged powdered metal and SilChromel, respectively. The exhaust valves on the LSA are not sodium filled either. The exhaust manifolds are cast iron rather than stainless steel as on the LS9 and the main bearing caps are nodular iron rather than steel.

The pistons in the LSA are hyper-eutectic cast aluminum rather than being forged. The piston skirts are polymer coated for improved scuff resistance and reduced NVH. The sumped top design of the pistons is retained, which allows for clearing the valves without machined valve pockets. The continuous surface free of edges helps to avoid hot spots that can contribute to pre-ignition.

The LSA also gets the dual pressure fuel system used in the the LS9, but the top pressure is reduced from 600kPa to 450kPa. The LSA gets the same beefed up block casting, seven-layer head gasket and 12mm head bolts as its big brother. The improved lubrication system including the squirters that spray oil on the bottom of the pistons is also retained. In total, the LSA and LS9 have about 100 new part compared to the LS7 in the current Corvette Z06. Of those, about twenty-five percent are common to both engines.

The end result is an engine that compared with the BMW M5 has 50 hp more at its peak and, more importantly, a much fatter torque curve. At 1,200 rpm the LSA is already producing more torque than the 383lb-ft that the M5 engine makes at its 6,100 rpm peak, and it never really lets up. It's the kind twisting force that gives you a shove in the back and just keeps pushing and pushing as long as the driver has the nerve to keep his or her right foot planted.

Sign in to post

Please sign in to leave a comment.

Continue