As gorgeous as the 2009 Corvette ZR1 may be on the outside, it's what is under the skin that gets our blood pumping. Fortunately, GM stripped down its new supercar to the bare essentials and put it on display here at the 2008 Detroit Auto Show.

You can access our gallery of ZR1 chassis photos by clicking on the photo above. We've also got commentary on what you're looking at after the jump.

You can access our gallery of ZR1 chassis photos by clicking on the photo above. We've also got commentary on what you're looking at after the jump.

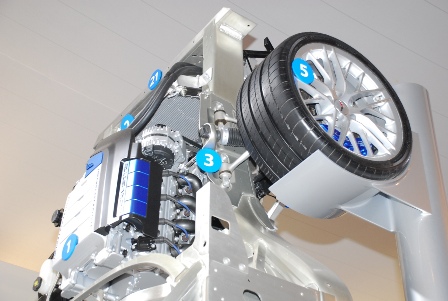

The Corvette is rather unique among volume production cars by virtue of its space-frame layout, which uses a self-supporting structure as shown above. Contrast this to the typical modern car, which largely relies on welded and bonded sheetmetal to bear the forces imparted by the suspension, passengers, cargo, powertrain, and other required components.

At the front of the car, tall tubular members help tie the suspension system into the firewall, much like the geometry that would be found at the front of a tube-frame race car chassis (although constructed rather differently).

At the very top of the picture is the large bumper beam that forms a significant part of the crash safety system.

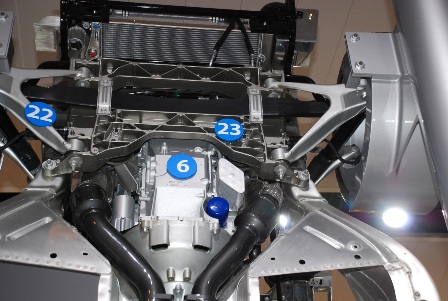

Underneath the front end, a magnesium engine cradle (23) supports not only the powerplant, but also the aluminum lower control arms (22). The radiator is located in front of this; it looks small in this picture because of the angle. The black band running above the "22" and "23" tags is the transverse composite leaf spring, which saves weight and packaging space compared to traditional coil springs.

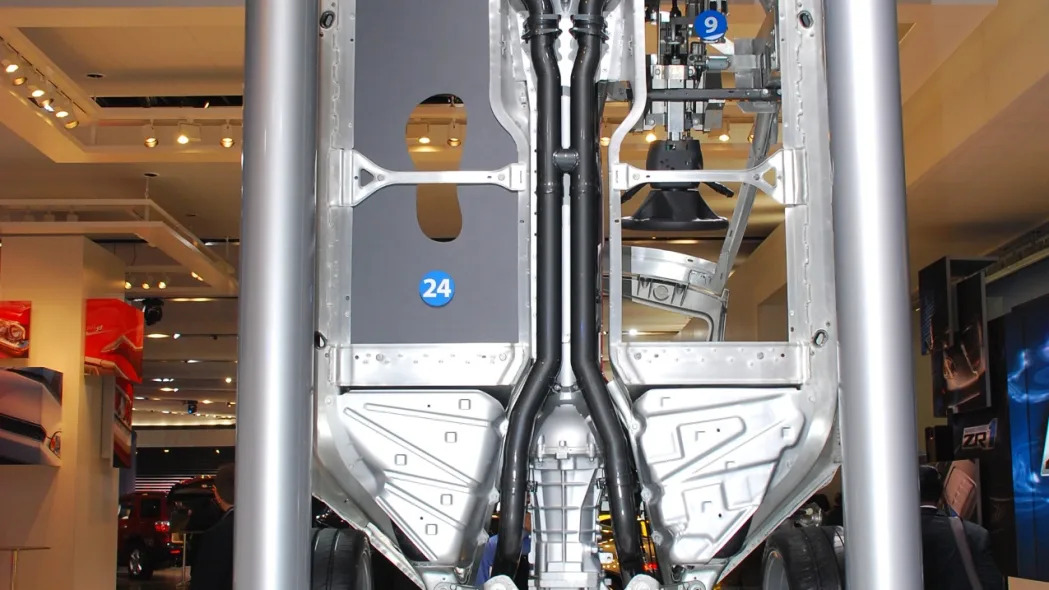

Just before the exhaust disappears into the frame, you can also see the close-coupled catalytic converters.

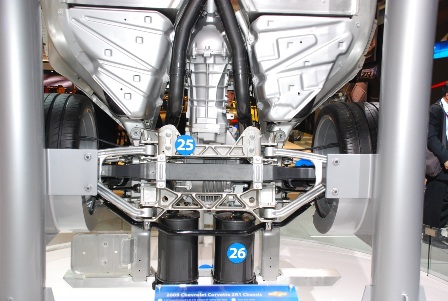

This shot clearly shows the front-engine/rear-transmission layout of the Corvette, but the exhaust system hides the large "torque tube" that ties together the two components.

A large plate normally covers the open bottom of the tunnel, which greatly improves the structural rigidity of the chassis.

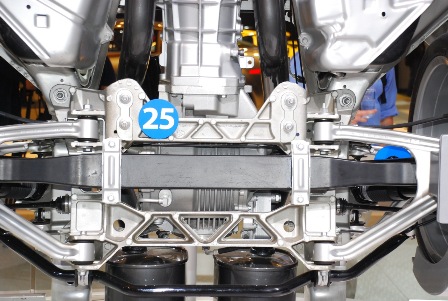

Another magnesium subframe appears at the rear of the car. While its job of resisting the torque reaction from the driveshaft and differential is made somewhat easier by the aforementioned torque tube, it's still a difficult task to keep the control arms, differential and chassis in alignment when all 595 lb-ft of engine torque are multiplied by the transmission and axle gearing. When the inertia of the rotating mass is considered, the instantaneous torque transmitted to the rear tires is immense - perhaps on the order of 8,000 lb-ft or more, depending on the tires, road surface, and mood of the driver.

Although not obvious here, GM uses unequal-diameter half-shafts in the rear - 40mm on the left, and only 33mm on the right. Although the manufacturer has not explicitly stated why it does this, it's very likely that the left shaft experiences larger torque loads during hard acceleration. Making both shafts the same diameter would result in increased weight, and the Corvette team fights for every pound.

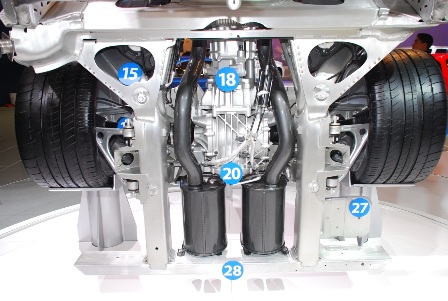

The titanium mufflers of the previous Z06 are gone, but in their place are these stainless-steel pieces with bypass valves (manufactured by Pierberg). Those who get a look at the ZR1's tail - that'd be most cars on the road - at least are treated to the sight of polished 4" tips.

The construction of the Corvette presents an interesting problem - where to store the fuel? The solution is to place twin tanks (15) ahead of the rear axle centerline, with a transfer system linking the two that allows the use of one filler neck.

The transmission (18) and rear diff (20) share a cooling system, which is a rather significant issue to address when one considers that the majority of powertrain losses - on the order of 10-15% - are dissipated in these two assemblies. For a 620-hp engine, that's up to 50 kW of power - enough to run several clothes dryers or electric ovens.

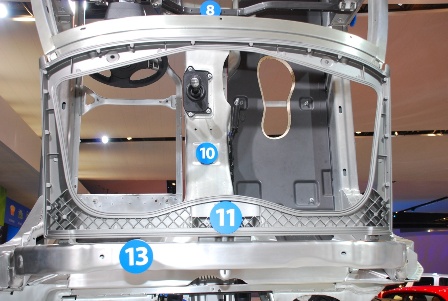

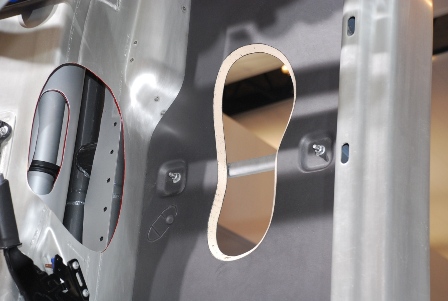

Magnesium is used once again for the roof structure. It's a material that's well-suited to this type of structural task - the strength-to-weight ratio is quite good, and better yet, modern processing technologies allow the metal to be injection-molded in its thixotropic (semi-solid) state - much like the way that plastic is processed. This results in a part with accurate details (like the honeycomb ribbing of the above part), which further improves the part's strength and stiffness.

Despite all the fancy materials used elsewhere, a balsa-wood composite is still used for the Corvette's floor. Don't be too critical, though - the material simply needs to act as a spacer between the two "skins", and balsa's mechanical characteristics and light weight make it perfect for this task.

Sign in to post

Please sign in to leave a comment.

Continue