Mechanically actuated valves may soon be a thing of the past. We've made over a century's worth of improvement on the same basic combination of a camshaft, followers (or lifters), a poppet valve and a spring. We've gone from using pushrods and rocker arms to actuate the valvetrain to direct-acting buckets motivated by an overhead camshaft with variable phasing and lift. While engineering ingenuity has managed to wring incredible performance and flexibility out of these setups, there's only so far you can go before bumping into the laws of physics. French automotive supplier Valeo SA has been working on camless engine technology for quite some time and they expect to have their system on the street by 2010 or 2011. Valeo is working with several automakers to implement the camless technology. Eliminating a traditional valvetrain is expected to yield efficiency improvements nearing 20 percent. An increase in performance and emissions decreases will also be realized from the system.

More after the jump

[Source: Valeo via Autoweek]

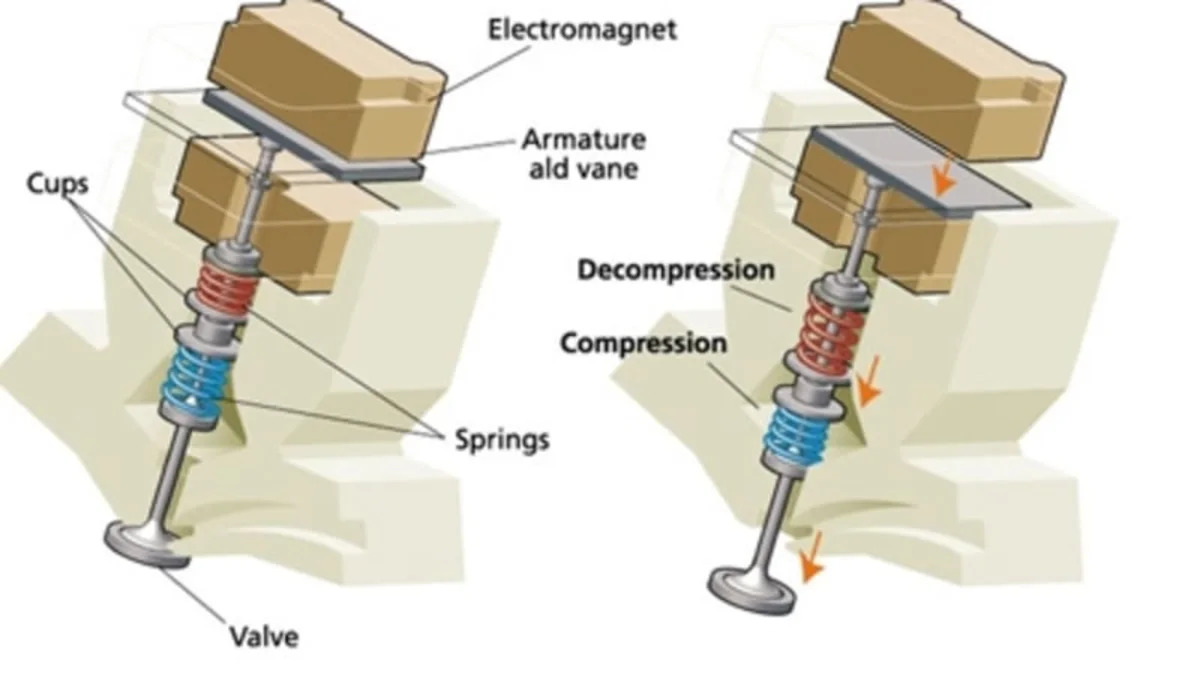

The Valeo system uses electromagnetic actuation. Where a typical valvetrain uses a spring to hold the valve closed until the camshaft lobe overcomes the spring, the camless system uses a pair of springs, and the valves default to a partially open position. There's a pair of electromagnets above the valve assemblies with an armature in between. The armature is what the electromagnetic fields move to actuate the valve. The upper electromagnet pulls the valve shut, and the lower electromagnet fully opens the valve. This system eliminates entirely the camshaft and its associated drive system such as belts, tensioners and bearings. High performance engines with variable timing and lift valvetrains will be easy to accomplish with the Valeo system, as opposed to the complex mechanical systems currently used to accomplish those functions. Think of Valeo's system as operating much like a fuel-injection system. Each valve event can be discrete and optimized. Low end torque will be increased, and cylinder head design can use more radical valve and port angles without having to fit rotating machinery above and around the cylinder head. Depending on the size of the hardware, packaging could approach the compact size of pushrod engines.

Think of it, your engine could switch run in the Atkinson cycle with cylinders deactivated at cruise and save a lot of fuel, switching over to the traditional Otto-cycle and all cylinders when more power is needed would be fast and seamless. While some engines can currently pull off cylinder deactivation, they can't switch cycles from the more fuel-efficient but less powerful Atkinson Cycle (or Miller-cycle when teamed with forced induction) and the "standard" four-stroke cycle. The biggest stumbling blocks for Valeo to overcome are developing sensors that are accurate and durable enough to make sure valve events occur exactly when they should and the system has a reasonable MTBF. Cost of the system will likely see it installed on premium and performance vehicles at first. Valeo has a "half-camless" configuration that offers eighty-percent of the benefit at half the cost of the full-camless system. We're excited to see this system hit the street. We're even more excited to see what the DIY aftermarket can do with this hardware - just imagine, a "camless retrofit-kit" for your classic car. You build and program the system, much the same as a MegaSquirt. That'd be great under the rear decklid of the Porsche 912 I lust for.

More after the jump

[Source: Valeo via Autoweek]

The Valeo system uses electromagnetic actuation. Where a typical valvetrain uses a spring to hold the valve closed until the camshaft lobe overcomes the spring, the camless system uses a pair of springs, and the valves default to a partially open position. There's a pair of electromagnets above the valve assemblies with an armature in between. The armature is what the electromagnetic fields move to actuate the valve. The upper electromagnet pulls the valve shut, and the lower electromagnet fully opens the valve. This system eliminates entirely the camshaft and its associated drive system such as belts, tensioners and bearings. High performance engines with variable timing and lift valvetrains will be easy to accomplish with the Valeo system, as opposed to the complex mechanical systems currently used to accomplish those functions. Think of Valeo's system as operating much like a fuel-injection system. Each valve event can be discrete and optimized. Low end torque will be increased, and cylinder head design can use more radical valve and port angles without having to fit rotating machinery above and around the cylinder head. Depending on the size of the hardware, packaging could approach the compact size of pushrod engines.

Think of it, your engine could switch run in the Atkinson cycle with cylinders deactivated at cruise and save a lot of fuel, switching over to the traditional Otto-cycle and all cylinders when more power is needed would be fast and seamless. While some engines can currently pull off cylinder deactivation, they can't switch cycles from the more fuel-efficient but less powerful Atkinson Cycle (or Miller-cycle when teamed with forced induction) and the "standard" four-stroke cycle. The biggest stumbling blocks for Valeo to overcome are developing sensors that are accurate and durable enough to make sure valve events occur exactly when they should and the system has a reasonable MTBF. Cost of the system will likely see it installed on premium and performance vehicles at first. Valeo has a "half-camless" configuration that offers eighty-percent of the benefit at half the cost of the full-camless system. We're excited to see this system hit the street. We're even more excited to see what the DIY aftermarket can do with this hardware - just imagine, a "camless retrofit-kit" for your classic car. You build and program the system, much the same as a MegaSquirt. That'd be great under the rear decklid of the Porsche 912 I lust for.

Sign in to post

Please sign in to leave a comment.

Continue