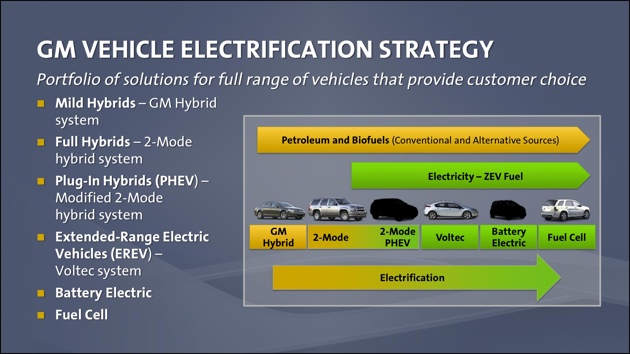

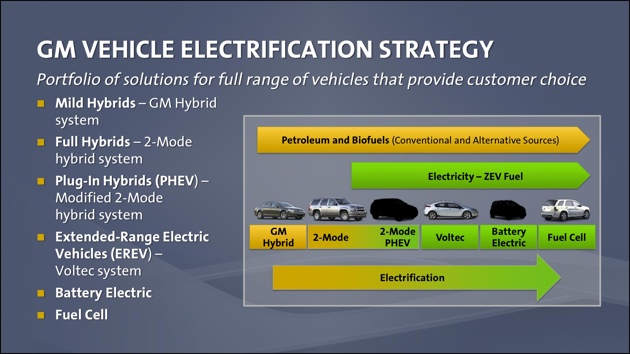

Over the past century, two of the primary ways that carmakers have been able to distinguish their products is styling and powertrains. While styling has often been outsourced to various design studios, typically only the smallest automakers outsource powertrains. As the industry heads into the era of increasing electrification, the whole concept of the powertrain is evolving.

General Motors has decided that powertrains will remain one of its core competencies whether they are based on internal combustion or transferring electrons. To that end, GM has announced that it will become the first U.S.-based automaker to design, develop and manufacture its own electric motors. GM will invest $246 million on a high volume motor production facility that starts production for 2013.

[Source: General Motors]

During a background briefing, GM's Pete Savagian explained that a fuel tank in a conventional vehicle corresponds to the battery of an EV, while the engine controller equates to the power electronics and inverter and the internal combustion engine is analogous to the electric motor. All of these are core powertrain elements and GM has already announced it will produce its own battery packs and electronics.

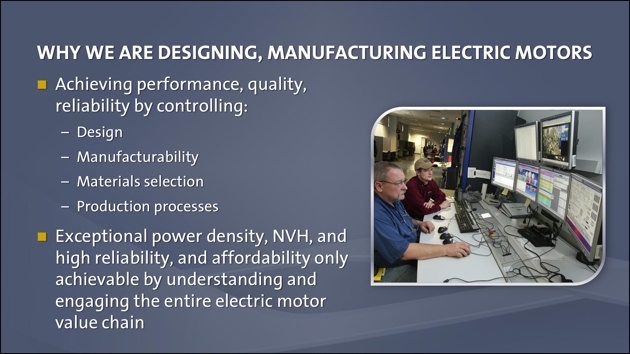

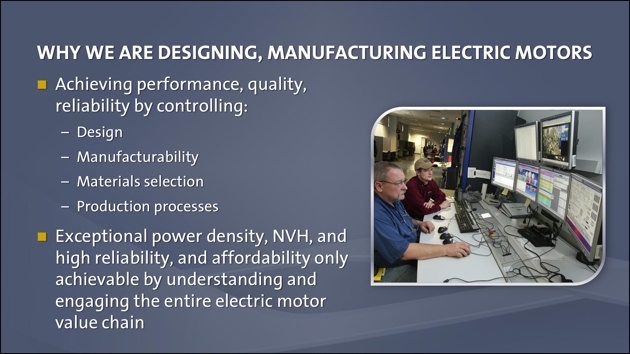

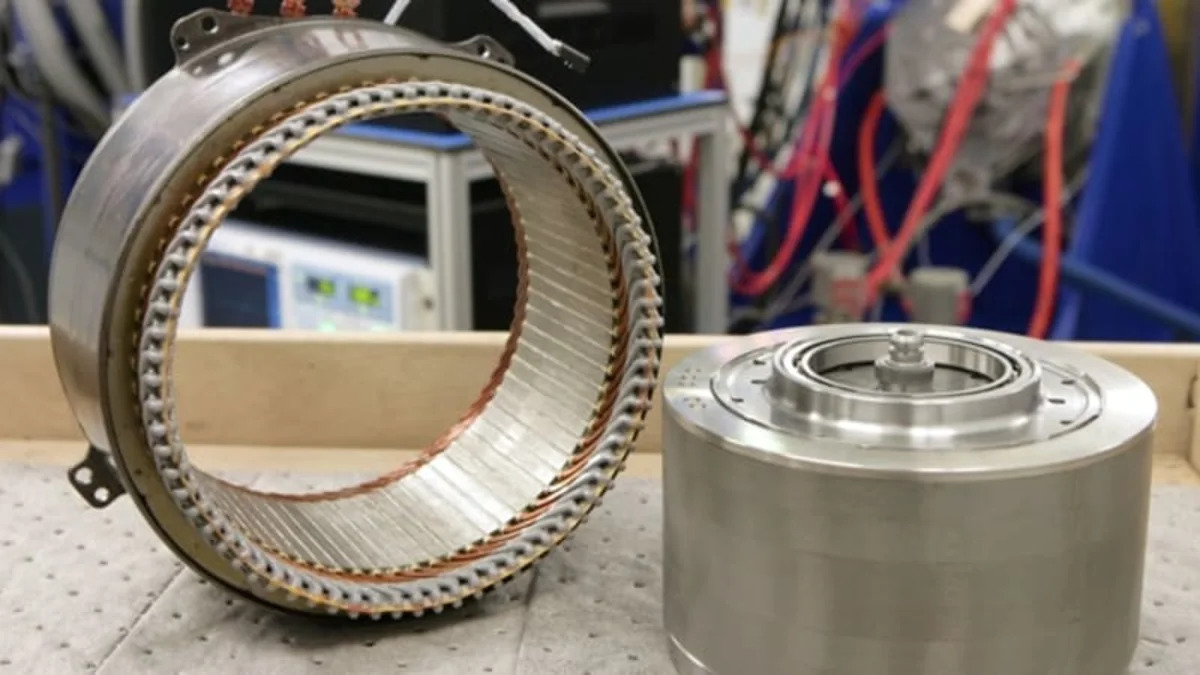

Building a basic electric motor is not very hard. Building a good electric motor suitable for use in an electric or hybrid vehicle is a lot more complicated. The operating environment for a car is among the most varied for any consumer product. Creating a product robust enough to last two decades under widely varying temperatures, vibration and usage patterns is a non-trivial matter.

GM has decided that it must take a more active role in motors in order to ensure that the electrical analog of the engine meets its strict requirements. Because the battery retains extraordinarily poor energy density compared to any liquid fuel, the engineers must make up for it in other areas including the motor. Savagian highlighted the power density of the motor as critical. GM's motor engineers are working to improve power density with a goal of doubling it in the coming years. Getting more power from smaller motors allows for more packaging flexibility while also keeping weight down.

Having a strong in-house knowledge base about motors is also expected to give GM an advantage in adapting to technological changes and supply issues. One of the questions raised during the briefing regarded the availability of rare earth metals such as Neodymium for use in permanent magnets for motors. Savagian acknowledged that supplies of these materials could be a problem in the future. He said that GM could build motors that don't use these materials and they are likely to use non-permanent magnet motors for some applications.

Having a strong technological basis will also help GM create motors that run smoothly and quietly. The motor used in the Chevy Volt is particularly quiet as we found when we drove the prototype back in December. At this time GM hasn't announced who will build the Volt motors, although it doesn't appear those will be produced by the automaker at first.

The first application for GM's new motors will be the next generation two-mode hybrids, which are coming in 2013. GM put out a media advisory that it will make an announcement on January 26, 2010 at its White Marsh, Maryland transmission plant, so it seems likely that the plant that builds the current two-mode transmissions will be home to GM's first big motor line.

General Motors has decided that powertrains will remain one of its core competencies whether they are based on internal combustion or transferring electrons. To that end, GM has announced that it will become the first U.S.-based automaker to design, develop and manufacture its own electric motors. GM will invest $246 million on a high volume motor production facility that starts production for 2013.

[Source: General Motors]

During a background briefing, GM's Pete Savagian explained that a fuel tank in a conventional vehicle corresponds to the battery of an EV, while the engine controller equates to the power electronics and inverter and the internal combustion engine is analogous to the electric motor. All of these are core powertrain elements and GM has already announced it will produce its own battery packs and electronics.

Building a basic electric motor is not very hard. Building a good electric motor suitable for use in an electric or hybrid vehicle is a lot more complicated. The operating environment for a car is among the most varied for any consumer product. Creating a product robust enough to last two decades under widely varying temperatures, vibration and usage patterns is a non-trivial matter.

GM has decided that it must take a more active role in motors in order to ensure that the electrical analog of the engine meets its strict requirements. Because the battery retains extraordinarily poor energy density compared to any liquid fuel, the engineers must make up for it in other areas including the motor. Savagian highlighted the power density of the motor as critical. GM's motor engineers are working to improve power density with a goal of doubling it in the coming years. Getting more power from smaller motors allows for more packaging flexibility while also keeping weight down.

Having a strong in-house knowledge base about motors is also expected to give GM an advantage in adapting to technological changes and supply issues. One of the questions raised during the briefing regarded the availability of rare earth metals such as Neodymium for use in permanent magnets for motors. Savagian acknowledged that supplies of these materials could be a problem in the future. He said that GM could build motors that don't use these materials and they are likely to use non-permanent magnet motors for some applications.

Having a strong technological basis will also help GM create motors that run smoothly and quietly. The motor used in the Chevy Volt is particularly quiet as we found when we drove the prototype back in December. At this time GM hasn't announced who will build the Volt motors, although it doesn't appear those will be produced by the automaker at first.

The first application for GM's new motors will be the next generation two-mode hybrids, which are coming in 2013. GM put out a media advisory that it will make an announcement on January 26, 2010 at its White Marsh, Maryland transmission plant, so it seems likely that the plant that builds the current two-mode transmissions will be home to GM's first big motor line.

Sign in to post

Please sign in to leave a comment.

Continue