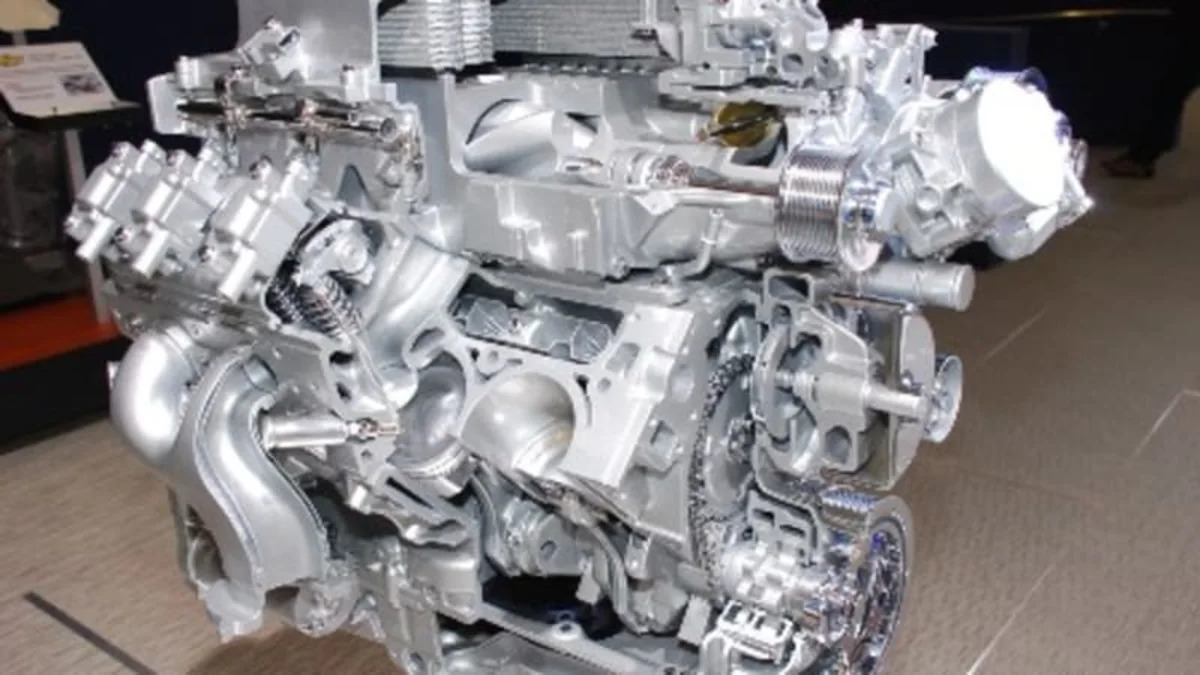

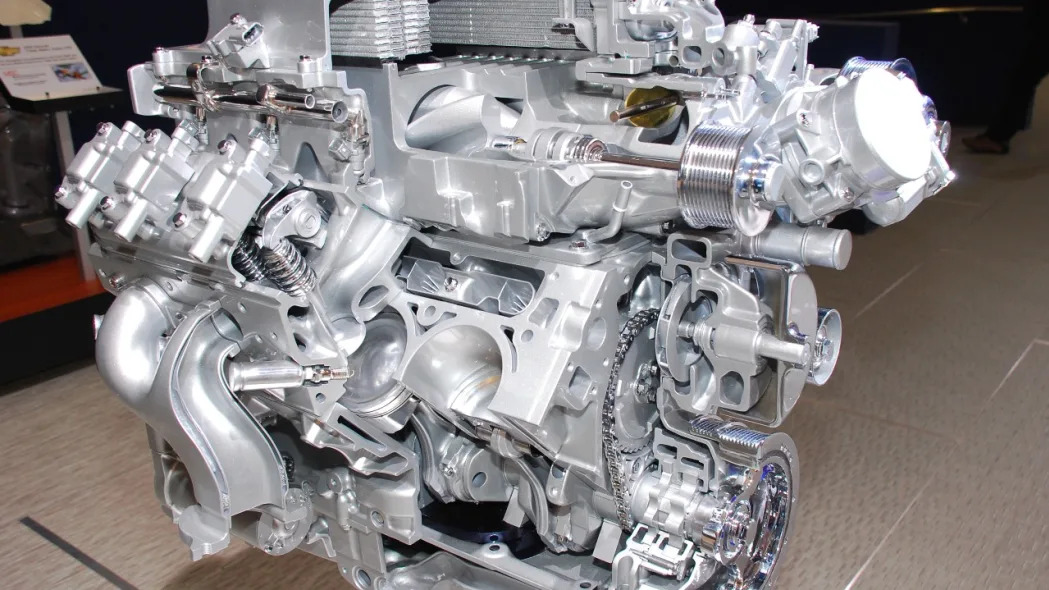

Yea, we know - the automotive press has featured a whole bunch of Corvette ZR1 content lately (including us!), and readers are probably getting a bit tired. However, we figure that a cutaway of the mighty supercharged LS9 should be interesting enough to justify yet another post on the revived King of the Hill.

Painted in monochrome silver as GM is wont to do, this particular display isn't particularly photogenic. Still, we were able to capture some details that aren't easily observed in 2D drawing or press releases, so click through the jump for a variety of shots.

Painted in monochrome silver as GM is wont to do, this particular display isn't particularly photogenic. Still, we were able to capture some details that aren't easily observed in 2D drawing or press releases, so click through the jump for a variety of shots.

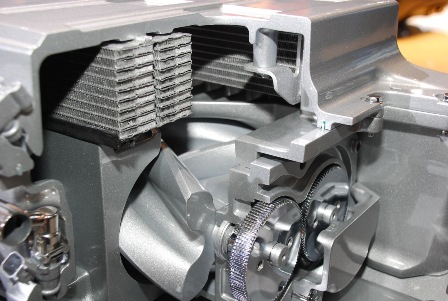

Here's a great shot of the helical rotors, but due to the paint, the specialized Teflon coating isn't visible. We have no idea how the rotors are fabricated, and GM's not talking - let's assume that it's a relatively exotic and expensive process.

Slightly unexpected was the use of straight-cut gears, which tend to be noisier than those cut on an angle. We wouldn't object to a bit of blower noise from under the hood, and besides, the loudest whining is likely to come from owners of more-expensive exotics.

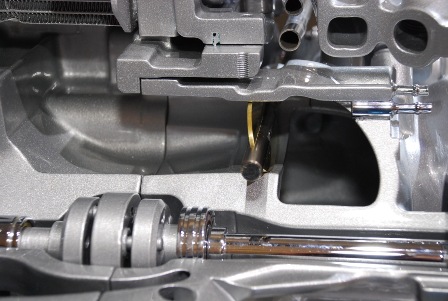

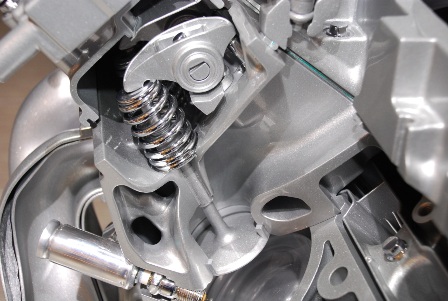

This is the bypass valve, which provides an alternative route around the supercharger during part-throttle operation. This improves part-throttle fuel economy by reducing the pumping losses of the blower.

Located at the bottom of this shot is the driveshaft for the supercharger - the drive pulley (off-screen to the right of this shot) is located about a foot ahead of the rotors.

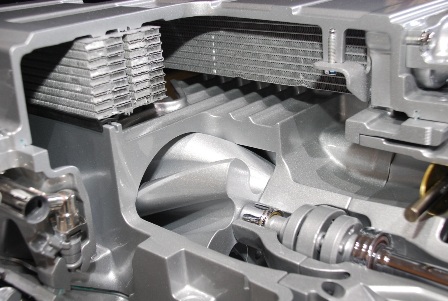

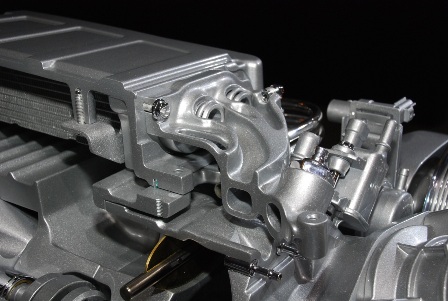

This shot clearly shows the intercooler assembly mounted atop the supercharger. In an actual ZR1, the clear window in the hood would be directly above this component. Note the ribbing used on the roof of the blower housing to help improve heat dissipation.

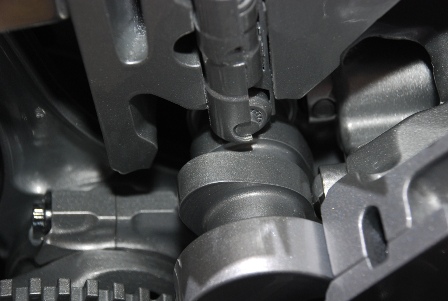

The heavily-dished piston is clearly evident here - it takes a lot of dish to reduce the compression ratio on an engine of this displacement, especially when combined with a small combustion chamber as utilized on the GenIII/IV engines.

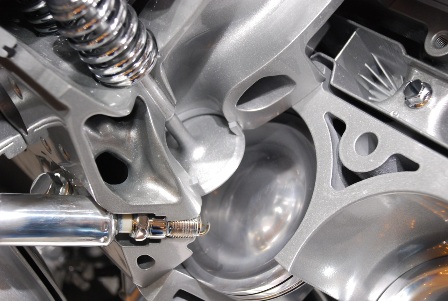

That, folks, is one nicely-shaped intake port. After "spending" so much horsepower to compress the intake charge, it'd be a shame to restrict its entry into the combustion chamber, and so the LS9 attempts to give the air a straight shot into the cylinder. The titanium valves are 2.2 inches in diameter; this is larger than what would normally be used on a naturally-aspirated engine, but the airflow requires of this engine far surpass that of GM's other 6.2L V8s.

These two passages provide routes for coolant into and out of the intercooler. Located off to the bottom right of this photo is the throttle body.

Getting the spent charge out of a forced-induction motor is an important task, and so the free-flowing exhaust ports combine with hydroformed tubular headers to create a path of least resistance.

Silver paint hides the beautiful color of natural titanium, which is used for the connecting rods. The pistons are forged, although that's difficult to tell from this particular angle.

While the camshaft used in the LS9 is significantly less aggressive than the bumpstick used by the higher-revving naturally-aspirated LS7, it still uses a healthy amount of lift. These lobes also have a fairly aggressive profile, which quickly opens and closes the valve and thus makes the most out of each actuation cycle. Roller camshafts make such profiles practical, but the valvesprings end up with a rather difficult job as a result.

Sign in to post

Please sign in to leave a comment.

Continue