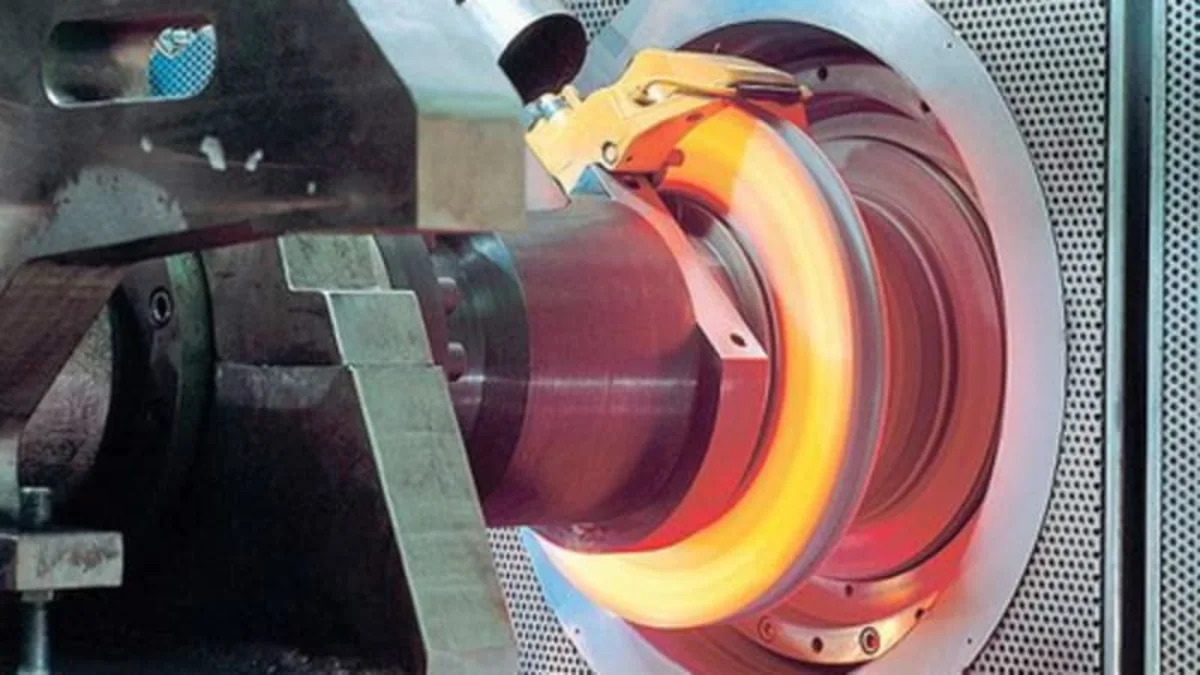

The sight of a race car streaking into the darkness, brakes aglow as it slows for the next corner, is one of those incredible images that just sticks with you. Those massive carbon-ceramic rotors can take a lot of abuse and their light weight and durability have made them a racing staple for more than 15 years now. Street cars, on the other hand, have been slow to adopt the technology. Although their superior performance is unquestionable, the high cost of carbon-ceramic brakes has made them pretty much exclusive to exotics and supercars.

Porsche was the first to use them on a street car when they fitted them to the "widowmaker" GT2. Soon after, they found their way onto the "regular" 911 Turbo as well. Now you can get carbon-ceramics on any Ferrari, most Lambos and Porsches, the Bentley Conti GT Diamond and the Audi RS4. But whereas half of Ferrari buyers splurge for the upgrade, only 6% of RS4 owners have done likewise. Why is that? Well, price surely must factor into it.

Although the carbon-ceramic brake discs last four times longer than conventional steel discs, they cost a heck of a lot more than traditional steel discs: $15 to $20 a disc for steel compared to $665 to $2,660 a disc for carbon-ceramic. That's quite a jump. But there may be hope. By switching from batch production to a continuous process, German manufacturer SGL Carbon AG, along with Audi, are trying to change that. If they can get the process perfected, they are expecting the price per disc to drop all the way down to $465.

Some still think that's too expensive to generate real mass appeal. Perhaps they'll still primarily be seen on sports cars and exotics, but the new, lower price would make them that much more attainable to the average Joe or Josephine who wants to autocross, say, their Mazda5 on weekends. Click through for the details about the new process and the specifics about why carbon-ceramics are so superior to steel.

[Source: AutoWeek]

Porsche was the first to use them on a street car when they fitted them to the "widowmaker" GT2. Soon after, they found their way onto the "regular" 911 Turbo as well. Now you can get carbon-ceramics on any Ferrari, most Lambos and Porsches, the Bentley Conti GT Diamond and the Audi RS4. But whereas half of Ferrari buyers splurge for the upgrade, only 6% of RS4 owners have done likewise. Why is that? Well, price surely must factor into it.

Although the carbon-ceramic brake discs last four times longer than conventional steel discs, they cost a heck of a lot more than traditional steel discs: $15 to $20 a disc for steel compared to $665 to $2,660 a disc for carbon-ceramic. That's quite a jump. But there may be hope. By switching from batch production to a continuous process, German manufacturer SGL Carbon AG, along with Audi, are trying to change that. If they can get the process perfected, they are expecting the price per disc to drop all the way down to $465.

Some still think that's too expensive to generate real mass appeal. Perhaps they'll still primarily be seen on sports cars and exotics, but the new, lower price would make them that much more attainable to the average Joe or Josephine who wants to autocross, say, their Mazda5 on weekends. Click through for the details about the new process and the specifics about why carbon-ceramics are so superior to steel.

[Source: AutoWeek]

Sign in to post

Please sign in to leave a comment.

Continue